50W LDMOSFET HF

linear amplifier for the Red Pitaya

Almost

four years ago, in early 2017, I decided to get into software-defined

radio, and for that purpose I bought a Red Pitaya board. The main

project

is a transceiver that has a high efficiency, legal-limit output stage

employing envelope elimination and restoration. I started doing the

development work, but I found rather little interest in such a

project among fellow hams. Some even ridiculed me for striving towards

highest possible efficiency, arguing that energy is cheap enough that

it's no problem to waste some. These reactions, along with the general

state of ham radio, which I perceive as being in serious decadence, damped my

motivation. I got lazy, and the project has been resting in a state of

half development for years.

Almost

four years ago, in early 2017, I decided to get into software-defined

radio, and for that purpose I bought a Red Pitaya board. The main

project

is a transceiver that has a high efficiency, legal-limit output stage

employing envelope elimination and restoration. I started doing the

development work, but I found rather little interest in such a

project among fellow hams. Some even ridiculed me for striving towards

highest possible efficiency, arguing that energy is cheap enough that

it's no problem to waste some. These reactions, along with the general

state of ham radio, which I perceive as being in serious decadence, damped my

motivation. I got lazy, and the project has been resting in a state of

half development for years.

But I did a lot of listening with the Red Pitaya and PowerSDR software,

which provides very much better performance and functionality than my

old conventional Kenwood transceiver. Only for transmitting I went

back to the Kenwood. Eventually the idea matured to build a little

amplifier that would allow me to put the Red Pitaya on the air, in a

basic way, with a usable power, although without the cost of a high

power amplifier nor the complexity of EER.

I had purchased a small, inexpensive, 70W-rated gemini LDMOSFET, intending to

use it as an expendable guinea pig in a scale model of the big

project's legal-limit class D final amplifier. So I decided to use this

device to build a provisional small amplifier for the Red Pitaya, laid

out in such a way that it can still be used for experimentation towards

the big project. Since the small, 13.8V-fed amplifier works with the

same drain load impedance as a big 50V-fed one, such experimentation is

quite realistic.

This little amplifier is an attempt at operation in totally, absolutely

conventional class AB, unlike most HF broadband push-pull amplifiers,

which are mixed-class designs, operating somewhere in the continuum

between class AB and current-switching class D. The idea was to provide as much signal

quality and efficiency as class AB can deliver. How much success I had

in this attempt will be shown further down this page, in the section

about test results.

The Red Pitaya delivers a maximum output power of

10mW, and

it's best to run it a few dB below its maximum output, so a 50W

amplifier needs to have about 40 to 42dB gain. While LDMOSFETs

are capable of very high gain at HF, 40dB is a little high. So I

decided to build a two-stage amplifier, and divide the gain roughly

equally between the two stages.

To keep the circuit simple, I wanted to use a single-ended class A

driver stage. I experimented with various FETs, but found that these

are simply too non-linear to use in single-ended circuits. It would be

necessary to bias them to a comparatively very high standing current in

order to get good linearity. BJTs are very much better in this regard,

being far more linear than FETs over a wide range of collector current,

thus allowing to bias them just high enough to avoid clipping on signal

peaks. Unfortunately production of RF power BJTs has essentially been

discontinued. But I have some in my junk box. I selected a very

antique but excellent 2N5109, fully knowing that the use of a

discontinued device won't be very popular with people who want to copy

my design but don't have such an animal in their junk boxes. Sorry... I

just used what I had!

The final stage is built around a modern LDMOSFET, an AFT05MP075N. This

device is intended for VHF and UHF final stages in mobile radios, and

is quite inexpensive. I ordered it from a Chinese provider, but it's also

available at several of the well-known mainstream parts suppliers.

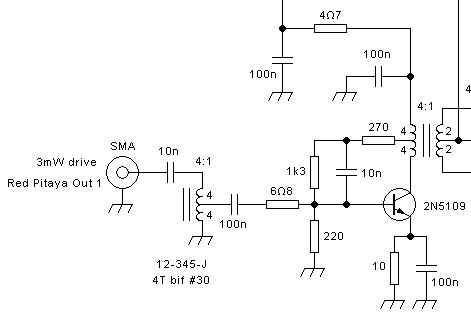

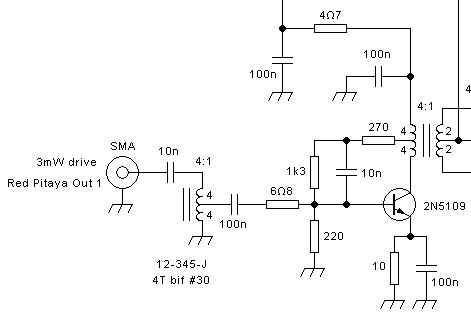

Without more ado, let's divide and conquer the schematic. You can get

the undivided and unconquered version by clicking on any of the parts.

The

driver stage uses strong collector-to-base feedback and no emitter

degeneration, to achieve stability and good linearity along with high

gain. The feedback pickup point is tapped down on the output

transformer in order to improve the stage's efficiency by

wasting less of its available RF output power in the feedback

circuit.

The

driver stage uses strong collector-to-base feedback and no emitter

degeneration, to achieve stability and good linearity along with high

gain. The feedback pickup point is tapped down on the output

transformer in order to improve the stage's efficiency by

wasting less of its available RF output power in the feedback

circuit.

Due to the lack of emitter degeneration, presence of negative feedback,

and the high gain of this transistor, which has a transition frequency

in excess of 1GHz, the base input impedance is very low, behaving quite

a lot like a constant-voltage current node. To get

enough

drive current the Red Pitaya's 50Ω output is transformed down in a 4:1

autotransformer, and a 6.8Ω resistor provides the missing resistance

between the stage's low input impedance and the 12.5Ω expected by the

transformer. This resistor also serves to isolate the transistor from

the Red Pitaya's output lowpass filter, to prevent any instability.

Actually the design value for this resistor was 8.2Ω. I used 6.8Ω

because I had no 8.2Ω SMD resistor in my junk box... If you have one,

use it, to get the stage's input impedance closer to 50Ω. But don't use a 10Ω resistor, as it would be

too high.

As is traditional in this sort of amplifier stage, the standing current

is controlled by the base voltage, defined mainly by the three

resistors biasing it, the supply voltage, and the resistor placed at

the emitter. It's approximately 77mA. The ease with which one can obtain a sufficiently stable bias current in a

simple circuit, without a need for adjustment, is one of the advantages

of BJTs over MOSFETs.

The input transformer is wound as four bifiliar turns of AWG #30

enameled wire twisted together using a drill, on a small Ferronics

12-345-J two-hole ferrite core. A suitable replacement for this core

would be an Amidon BN-43-2402.

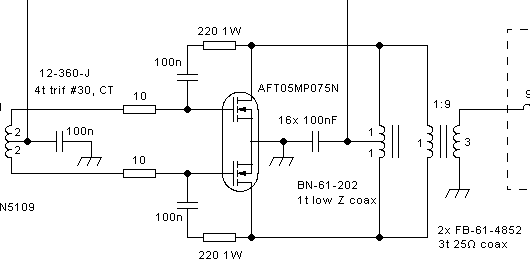

The interstage transformer is more complex: It's a trifiliar winding,

with one of the windings being center-tapped. To make this, a piece of

wire is bent into a T shape, the downgoing bar of the T consisting of a

wire loop forming the tap. This loop is twisted together just to give

mechanical support. Then two more wires are placed along the horizontal

part of the T, and the wire bundle is twisted together using a drill.

The core is wound with 4 turns of this bundle, of course

winding

2 turns in each direction from the center tap. Then the wire ends are

properly sorted out. The center tap of the secondary, and also the tap

for the feedback resistor between the two primary wires, are soldered

together to as close as possible to the core, to minimize the

inductance they put in the path of currents flowing in the transformer.

The core I used is a Ferronics 12-360-J, which is a somewhat

larger two-hole core. The Amidon equivalent is the BN-43-1502. Be

careful about replacements for this core, because it's working

relatively close to its saturation limit, courtesy of its high

permeability and of the class A amplifier's standing current. If you

use a higher permeability, the core will saturate, and with a much

lower permeability it will give insufficient reactance on the lowest

bands. So if you have to find a replacement of your own, make sure that

not only the dimensions are close, but also the permeability.

The

input transformer is far less critical in this regard, and a higher

permeability will work fine as long as the material isn't too lossy.

The transistor works into a total load of roughly 200Ω. This is defined

by the final stage's input resistance of around 60Ω, transformed to

roughly 240Ω by the interstage transformer, and by the tapped-down 270Ω

resistor, which acts like 1080Ω in parallel with those 240Ω.

No frequency compensation is used. Thanks to the transistor's high

transition frequency, its current gain is still above 30 at the highest

operating frequency. The peak base drive current should end up below

2mA. Compared to the 28mA available from the drive transformer this is

small enough to cause only a very slight gain reduction at the high

frequency end. The feedback resistor takes up the excess drive current,

and also swamps the transistor's small input capacitance by providing a

very low drive source impedance. All this is part of the beauty of

using UHF transistors at HF!

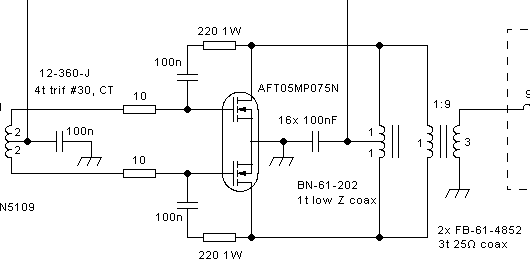

The

final stage is an attempt at making a true, real, traditional,

conventional class AB push-pull amplifier. The drive signal is applied

symmetrically and ground-referenced, using a real, properly functioning center

tap on the interstage transformer. The drains are tightly coupled

together by means of a feed transformer designed for the lowest

possible leakage inductance, and the physical assembly is also

designed to minimize stray inductance in the relevant

circuit.

All these points are often disregarded by amplifier builders, either

intentionally or due to lack of understanding, resulting in sort-of class D

amplifiers rather than true class AB. While class D amplifiers pressed

into sort-of-linear service have some advantages of their own, they

also suffer from considerable problems.

The

final stage is an attempt at making a true, real, traditional,

conventional class AB push-pull amplifier. The drive signal is applied

symmetrically and ground-referenced, using a real, properly functioning center

tap on the interstage transformer. The drains are tightly coupled

together by means of a feed transformer designed for the lowest

possible leakage inductance, and the physical assembly is also

designed to minimize stray inductance in the relevant

circuit.

All these points are often disregarded by amplifier builders, either

intentionally or due to lack of understanding, resulting in sort-of class D

amplifiers rather than true class AB. While class D amplifiers pressed

into sort-of-linear service have some advantages of their own, they

also suffer from considerable problems.

The output transformer is a conventional 1:9 design, which

results in utmost circuit simplicity and also a very short delay, when

compared to transmission line transformers. The short delay is a huge

advantage when it comes to controlling the drain voltage or current

waveform by means of suitable lowpass filters.

I didn't use the very widespread construction technique consisting of

a tube-and-sheet primary, with the secondary threaded through the

tubes, because the performance of this arrangement is relatively poor,

suffering from high leakage inductance, which has to be compensated

for, and limits high frequency response. Instead I wound the

transformer with homemade 25Ω coax cable, using the inner conductor as

secondary and the shield as primary. This results in significantly

lower leakage inductance.

The amplifier employs direct negative feedback, which is effective both

in common mode and in differential mode. Given the value of the

feedback resistors, the transconductance of this LDMOSFET, and

the

drain load resistance, the feedback circuit causes approximately a 20Ω load

on each gate. This is low enough to reasonably swamp the 170pF total

input capacitance of each gate. At 30MHz the gain is slightly lower

than at low frequencies, but not excessively so. Swamping the gates

through negative feedback is far better than doing so through resistors

to ground, because the negative feedback improves linearity and

stability.

10Ω resistors are used in series with each input side to provide some

isolation to the driver and prevent oscillations involving

resonances between the interstage transformer and the LDMOSFET's capacitances, by

de-Q-ing those resonators and thus drastically reducing any phase

rotations caused by them.

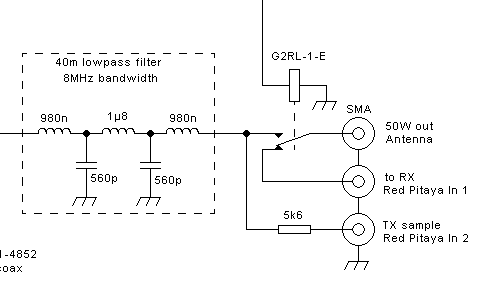

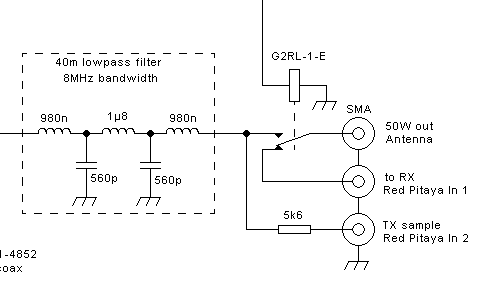

Broadband

RF amplifiers inevitably require lowpass filters to meet spectral

purity requirements. And particularly if they will be driven into some

degree of saturation! I have been in contact with a few hams who are

trying to build linear amplifiers that are naturally clean enough to

meet regulations without such filters, but this is an elusive

goal. At the end of the day, lowpass filters are still the

simplest, cheapest and most efficient way to get the harmonics low

enough.

Broadband

RF amplifiers inevitably require lowpass filters to meet spectral

purity requirements. And particularly if they will be driven into some

degree of saturation! I have been in contact with a few hams who are

trying to build linear amplifiers that are naturally clean enough to

meet regulations without such filters, but this is an elusive

goal. At the end of the day, lowpass filters are still the

simplest, cheapest and most efficient way to get the harmonics low

enough.

I was too lazy to build a whole bank of lowpass filters, one per band

or at least one per octave, with relay switching. Since almost all of

my HF activity is on 40 and 80 meters, I just built a single 40m

lowpass filter, mounted directly on the amplifier board, and I'm using

the amplifier on the air on 40 and 80 meters. For testing on other

bands I unsolder that filter (just the input and output wires) and

either measure without a filter, or with another filter quickly built on the board. It's very important to note in this context

that testing an amplifier with or without lowpass filter is very

different, and the results of one kind of testing should never be mixed

up with those of the other method. What counts is the tests done with

the correct lowpass filter. Any tests done without a lowpass filter are just additions, useful to test

for some specific problems.

I used an inductive-input (T-layout) filter with a low-ripple Chebyshev

response. It has nice standard values for capacitance, by

slightly

tweaking the cutoff frequency, but I still didn't have suitable 560pF

capacitors, so I had to use combinations in parallel. Murphy never

sleeps. The inductors are air-wound, for simplicity, adjustability and cheapness.

Please note that it's definitely not a matter of personal preference

whether to use a T filter or a π filter! The correct type of filter to

use depends on the amplifier type. Transistors are controlled current

sources, so a linear amplifier working without feedback forces the

output current while being voltage-flexible. This is a good match to π

filters, because they tend to force the voltage waveform but accept any

strange current waveform. But when strong negative feedback is added to

a linear amplifier, it behaves very close to an RF voltage source,

forcing the voltage while being current-flexible. Such an amplifier requires T

filters, which force the current waveform and accept the voltage

waveform forced by the amplifier.

If an amplifier is used in hard saturation, it's important to

understand whether it will clip the voltage or the current while

staying in saturation, as this will determine the type of filter to use.

That means, voltage-switching class D amplifiers need T filters, while

current-switching class D amplifiers need π filters.

And when a linear amplifier is slightly driven into saturation, the

type of filter required might change when it saturates! It's important

to avoid this situation. Linear amplifiers that degrade into

voltage-switching class-D when saturating should use strong negative

feedback, to always be voltage sources, while linear

amplifiers

that degrade into current-switching class D when saturating shouldn't

use direct negative feedback. Source degeneration would be OK, though.

Using an amplifier with the wrong type of lowpass filter results in

much lower efficiency! This lurking dragon has bitten many circuit

designers!

For a lowpass filter to have the desired effect on the amplifier, it's

essential that the filter is close enough to the MOSFETs, in terms of

electrical wavelength at the strongest harmonics. This is easy to

achieve with a conventional transformer on the lower bands. It starts

becoming a problem on the higher bands, and is a big problem when using

transmission line transformers or outboard lowpass filters. In those

situations many designers find that they need to use diplexer filters,

adding complexity and loss.

In the configuration I use my 50W amplifier on the air, with the 40m

lowpass filter directly on the board, behind a relatively small

conventional transformer, I have an easy and almost ideal situation,

which facilitates getting high performance.

The lowpass filter is followed by a simple relay for antenna switching.

During RX the antenna is passed over to the Red Pitaya's input #1.

There is also an ultra simple voltage divider, consisting just of a

5.6kΩ resistor and the 50Ω load that's connected to it, to

provide

a sample of a suitable level to the input #2 of the Red Pitaya, which

can be used to provide RF feedback for adaptive predistortion

of

the drive signal. This results in an extremely clean transmitted signal,

and allows some other tricks, as I will explain near the end

of

this page. For now, let's leave the predistortion turned off, and treat

this amplifier as a standard linear one.

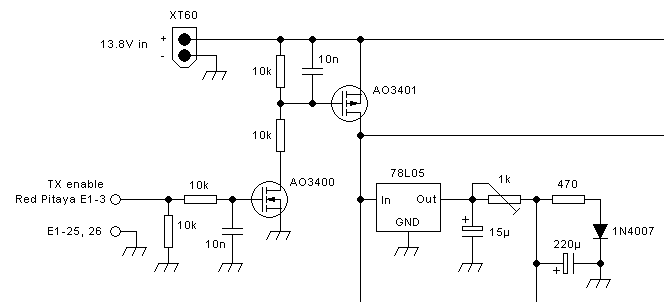

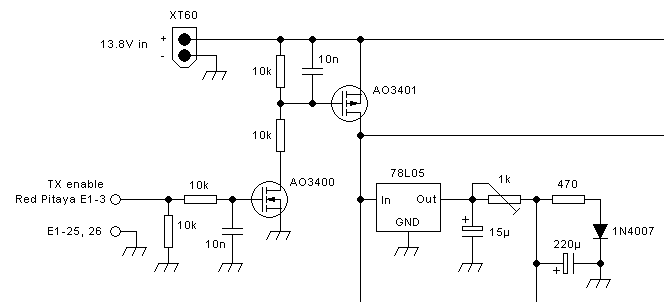

TX/RX

switching is controlled by an auxiliary output of the Red Pitaya, that

works at 3.3V CMOS levels. A very basic two-stage switching circuit,

using tiny but very capable N-channel and P-channel MOSFETs, controls

the power supply to the driver stage, the final stage's bias circuit,

and the relay coil. RC lowpass filtering is included to keep the little

FETs from embarking in any mischief if there is RF pickup. It also

moderates the inrush current charging the bypass capacitors.

TX/RX

switching is controlled by an auxiliary output of the Red Pitaya, that

works at 3.3V CMOS levels. A very basic two-stage switching circuit,

using tiny but very capable N-channel and P-channel MOSFETs, controls

the power supply to the driver stage, the final stage's bias circuit,

and the relay coil. RC lowpass filtering is included to keep the little

FETs from embarking in any mischief if there is RF pickup. It also

moderates the inrush current charging the bypass capacitors.

It seems that the day I designed this switching circuit I wasn't very

creative regarding component values...

As long as the TX enable input is low the entire circuit consumes no

power, doing away with the need for a power switch.

The bias circuit consists of a small 5V regulator, followed

by an

adjustable voltage divider with a slight temperature compensation

provided by a diode. The resistor values are low enough to provide a

low bias source impedance, which is further lowered in the audio and LF

ranges by an electrolytic capacitor, an in the HF and higher

ranges by a ceramic bypass capacitor located at the center tap of the

interstage transformer.

The temperature compensation provided by the single diode is

insufficient to fully compensate drift when the LDMOSFET warms up, but

is good enough for practical operation. When warm, the idling current

might be 10% higher than when cool. It might be better to use two

diodes in series, and reduce the value of the 470Ω resistor, to get

more complete thermal compensation.

I used a very slow, old and common high voltage rectifier diode here,

because it's placed right on top of the LDMOSFET, exposed to a

significant RF field. This diode is simply too slow to rectify

that RF, so there

will be no problem.

I used an XT60 connector for the 13.8V input. I got to know these in

the model aircraft world. They are inexpensive, compact, capable of

carrying 60A, and very good. They are tremendous overkill in this

amplifier, but I think that it's a good standard to use for low

voltage, moderate to high current connections in the ham shack.

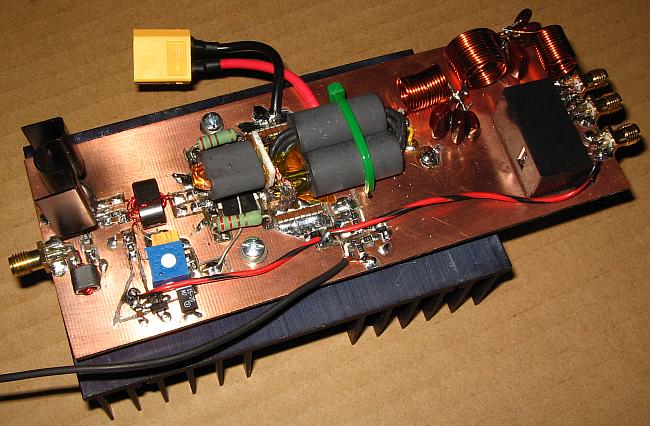

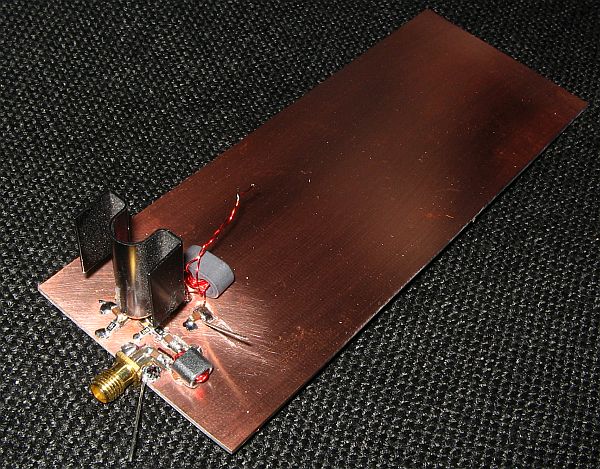

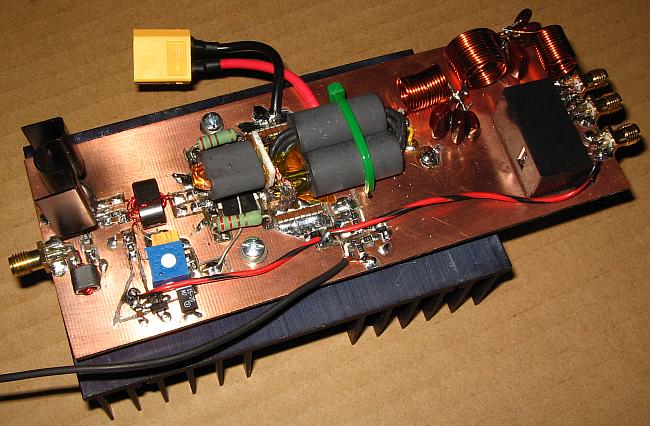

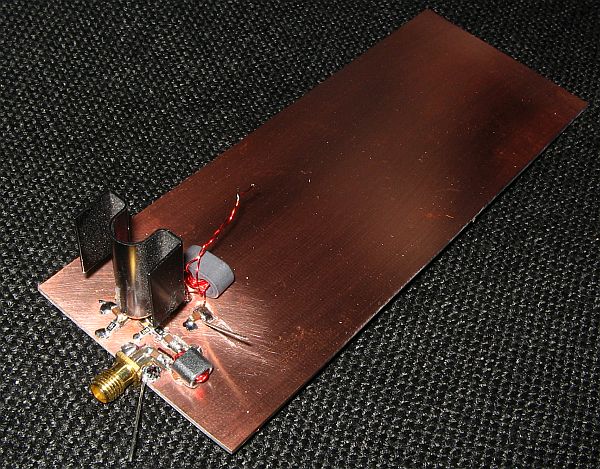

Construction

This

amplifier isn't build on a PCB. Instead I built it on a GCB: A gnawed

circuit board! I commissioned a rat to gnaw it for me. That rat has "Dremel"

printed on its back. The background of this decision is twofold: One is

that I temporarily lost my capability for making PCBs, because - again!

- my umpteenth inkjet printer failed and my laser printer absolutely

refuses to make decent PCBs, and the other is that in my old age (55,

but I feel like 85) I have increasing trouble concentrating for long

enough to imagine a whole project in my head and design a board for it

in one pass.

This

amplifier isn't build on a PCB. Instead I built it on a GCB: A gnawed

circuit board! I commissioned a rat to gnaw it for me. That rat has "Dremel"

printed on its back. The background of this decision is twofold: One is

that I temporarily lost my capability for making PCBs, because - again!

- my umpteenth inkjet printer failed and my laser printer absolutely

refuses to make decent PCBs, and the other is that in my old age (55,

but I feel like 85) I have increasing trouble concentrating for long

enough to imagine a whole project in my head and design a board for it

in one pass.

So I got my rat by the tail, grabbed a piece of double-sided PCB/GCB

stock, and had the buzzing animal gnaw my board step by step, stage for

stage, area by area, as construction progressed.

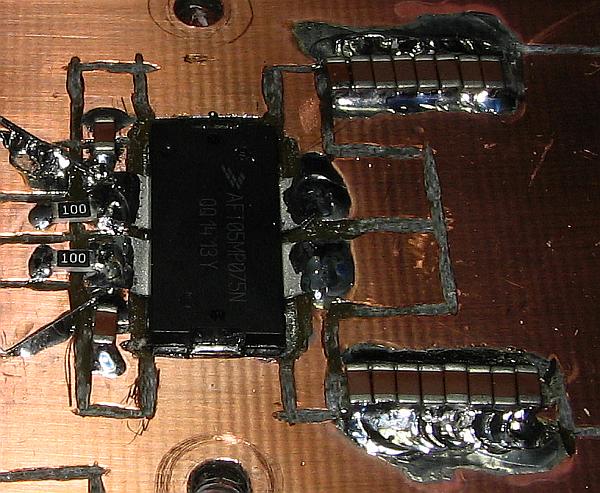

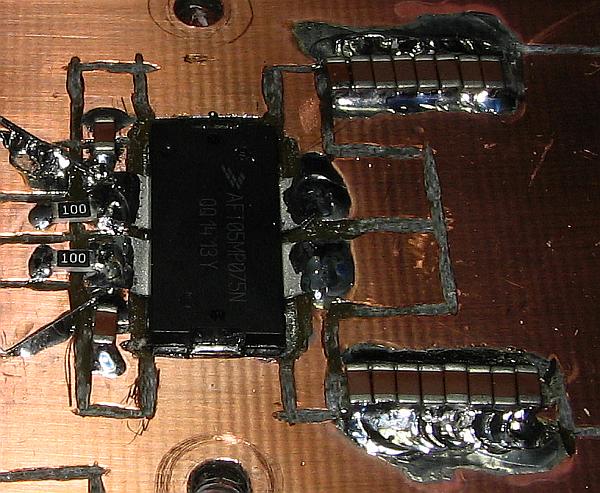

This photo shows the driver stage, temporarily with a

different,

simpler output transformer, fully operational for testing and approving

before continuing the construction.

I decided to use mostly SMD components because they are cheap, good for

RF, and over the years I have collected enough of them to be able to

largely build circuits using them. Some arrived as gifts, others

were bought. I have standardized on the 1206 size as much as possible,

because I can handle and solder them using just a strong magnifier.

Smaller ones would require a microscope...

It would have been nice to use an SMD transistor instead of the old

leaded, metal-cased one,

but there are few, and not as good as the 2N5109. If you absolutely

must use an SMD transistor, you could try the PZT2222A, but its

dissipation rating is very tight for this application, and its

transition frequency is much lower, so it will probably have a very

noticeable gain fall-off on the higher bands. The old 2N5109 is

certainly much better.

Please

excuse my rat for the unclean gnawing. The rat driver is old and can't

see very well, even when using a magnifier. For the same

reason,

please excuse my soldering iron for doing a sometimes messy job. The

circuit works, and that's good enough at this stage of life.

Please

excuse my rat for the unclean gnawing. The rat driver is old and can't

see very well, even when using a magnifier. For the same

reason,

please excuse my soldering iron for doing a sometimes messy job. The

circuit works, and that's good enough at this stage of life.

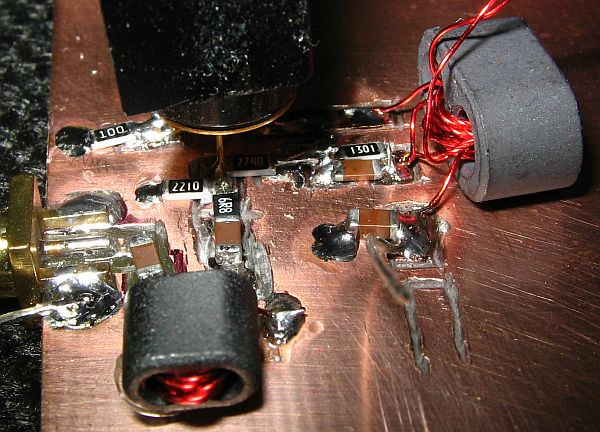

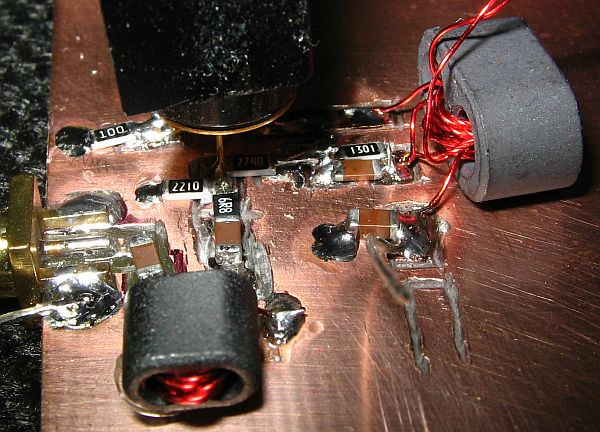

Some details of the output transformer wiring can be seen here quite

clearly. The shorter you get those wires, the better, although a few

extra millimeters aren't a big problem, given the comfortable

impedance

this transformer works at.

Note that I kept the groundplane as continuous as possible, leaving

copper ground bridges in place between parts and under some parts. This

allows getting away without drilling holes to connect to the underside

of the board. If you are less lazy than I am, then be so good and place

a connection through the board at each of those places where something

connects to ground. Specially the bypass capacitors at the

supply

point and at the emitter. It might cause a tiny performance improvement

at the high frequency end.

The transformers can be stuck to the board using hot glue, or double-sided foam tape.

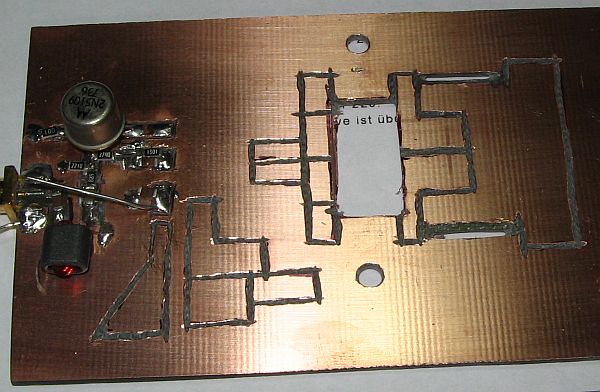

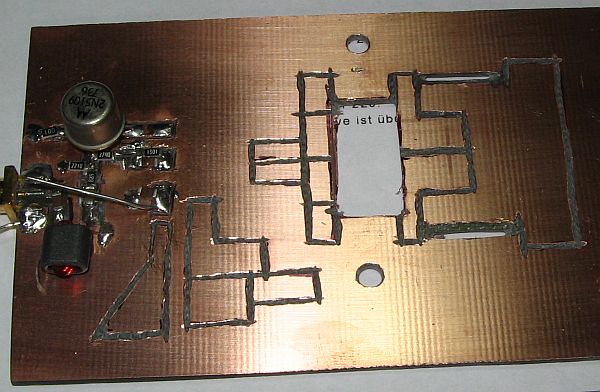

My rat was very happy to

get that much board to gnaw. It's the whole layout for the power stage

and bias circuit.

My rat was very happy to

get that much board to gnaw. It's the whole layout for the power stage

and bias circuit.

The big cutout is for the LDMOSFET, of course, and the round holes are

for screws that will mount the whole assembly to a heatsink. But pay

special attention to the two slits, gnawed out with a Dremel cut-off

wheel. I soldered strips of copper tape through these slits, to get a

very low impedance connection between the top side and the bottom side

ground foils there. The performance of a true class AB amplifier stands

and falls with this. The drain bypass capacitors need to provide a low,

very low, really truly

low inductance connection to the LDMOSFETs source.

If you have a board made by a PCB company, place at least two tightly spaced

rows of vias along these lines, instead of the slits.

After

soldering the copper tapes into the slits, I soldered 8 bypass

capacitors along each slit, to get a nice low impedance there, and to

distribute the current so that the caps can handle it.

After

soldering the copper tapes into the slits, I soldered 8 bypass

capacitors along each slit, to get a nice low impedance there, and to

distribute the current so that the caps can handle it.

Many builders don't realize how high the RF current in a

class AB

push-pull amplifier's bypass capacitor is! Until it's too late, that

is, until the underrated caps they use blow up. More usually than not,

the maximum current for a cheap SMD capacitor isn't specified. The

options a ham has are to either pay premium prices for RF-rated

capacitors, or do what I did: Use so many in parallel that

trouble

is unlikely. They are cheap enough!

This LDMOSFET is designed to be mounted through boards that are only

0.8mm thick, half of the normal thickness of traditional PCBs.

Since I don't have any such board material, but I do have a large

amount of high quality 1.6mm thick board stock that was given to me by

a fellow ham from the USA, I used some of that, and had my rat gnaw

45-degree chamfers along the edges of the cutout where the

transistor tabs end up. After soldering the transistor to the

heat spreader I bent and soldered down the tabs. It's definitely not

the best way to solve this problem, so if you can get 0.8mm board for

this project, get it.

The heat spreader is a 50mm long piece of 40×5mm silver-clad copper bus

bar, which I also got for free from a friend. Bus bar is a great

material for this purpose, because it's high purity copper and has nice

flat surfaces. Silver plating is nice to have, as it eases the

soldering job, but it's not required. I cut, deburred and drilled that

piece, then drilled the holes in the GCB by using the

spreader as

a template (lazy man's method to avoid measuring).

The spreader doesn't need to be this large and thick. 40×30×3mm would be plenty. I just used what I had.

To solder the transistor and the spreader to the board, I cleaned

everything, applied solder paste to the whole spreader surface, then

screwed the spreader to the board using long spring-loaded screws, then

clamped the board in a horizontal position, placed the transistor in its

hole (correctly oriented!), then heated up the spreader from below,

using a small jeweler's blowtorch. It smoked like an old steam engine,

then the solder melted, the spreader seated itself snugly against the

board's underside, some solder squeezed out, and the transistor of

course followed the laws of molecular attraction, and those of Murphy,

and snugged up as much as it could to one corner. I had to use some tools

to push it into a more suitable location and hold it down there while

the solder solidified. I don't know whether there are solder voids, but

I don't think so, because the flux seems to have almost fully

evaporated, and it seemed to come out of the joint before the solder

did. In any case this transistor has a very generous dissipation

rating, the copper heat spreader I used is also very generously sized

for this power level, so I have no worries about overheating the

transistor in use.

This sort of fully soldered mounting achieves the best possible thermal

and electrical conductivity. It's very much better than alternative

methods in which the spreader isn't soldered to the board.

Also

this is a very solid, robust and simple assembly.

Should it ever become necessary to replace the transistor, this can be

done by removing the board from the heatsink, cutting off the

transistor tabs, heating the spreader, picking off the transistor

corpse, sucking up old solder, then letting the thing cool. Then remove

the tabs, clean everything, apply fresh solder paste to the transistor

mounting area, put the new transistor in place, and reheat the spreader.

Note that I soldered wire jumpers from the gate areas to ground, to

protect the LDMOSFET gates during all this work. Better safe than

sorry.

The

next step was building and installing the output transformer. It has 3

turns of 25Ω coax cable, starting and ending on the output

side. On the input side the braids of all three turns are cut,

and

soldered to the LDMOSFET drains as shown here, to form a single-turn

primary winding consisting of the three parallel-connected braids.

The

next step was building and installing the output transformer. It has 3

turns of 25Ω coax cable, starting and ending on the output

side. On the input side the braids of all three turns are cut,

and

soldered to the LDMOSFET drains as shown here, to form a single-turn

primary winding consisting of the three parallel-connected braids.

My intentions were nicer than the outcome. I intended to place the

three turns nicely and orderly against the board, like three U shapes

nestled into one another. But the rather stiff coax cable, my even stiffer

arthritic fingers, and my old and presbioptic eyes decided otherwise.

It looks messy, and it is, but it ended up correctly connected...

This method of connecting the primary side minimizes leakage

inductance.

On the output side two of the turns simply loop, while the third one is

the start and end of the secondary winding. The center conductor of the

ends is connected to ground and the output point, while the two braid

ends are soldered together.

The outer insulation of the coax cable isn't

electrically required. The transformer would work the same if

the

three braids were in random contact along their whole length, or even

soldered together. I used an outer layer only to hold the braid tightly

to the dielectric, to keep the cable's impedance from rising.

25Ω

coax cable can be bought ready-made, but only from specialist

companies, and at prices that are much stiffer than the cable. For that

reason I made my own. I used a piece of stranded, silver-plated,

teflon-insulated wire, having an overall diameter of 1.3mm, and pulled

the braid of some good quality RG-174 cable over it. Then I pulled a

very tightly fitting heat shrink tube over that, and heated it. The

result is a coax cable that should have roughly the correct impedance,

thanks to the wire being much thicker than RG-174's center conductor,

the other dimensions being about the same. I didn't measure the actual

impedance of this cable, but anyway it's not terribly critical, given

that the total length of the three turns is only about 28cm.

25Ω

coax cable can be bought ready-made, but only from specialist

companies, and at prices that are much stiffer than the cable. For that

reason I made my own. I used a piece of stranded, silver-plated,

teflon-insulated wire, having an overall diameter of 1.3mm, and pulled

the braid of some good quality RG-174 cable over it. Then I pulled a

very tightly fitting heat shrink tube over that, and heated it. The

result is a coax cable that should have roughly the correct impedance,

thanks to the wire being much thicker than RG-174's center conductor,

the other dimensions being about the same. I didn't measure the actual

impedance of this cable, but anyway it's not terribly critical, given

that the total length of the three turns is only about 28cm.

I used two Amidon FB-61-4852 ferrite sleeves, which give plenty enough

inductance for 160m, more than enough voltage handling for 13.8V

operation at low loss, and also can handle considerable DC without

saturating. Given that no DC blocking capacitor is used, any small

difference in the resistances of both sides of the feed transformer

will result in a DC flowing in the output transformer's primary, so this point

needs to be considered. Don't replace these cores by any having a higher

permeability!

The three turns of coax cable fit tightly through the holes of

these cores.

The

feed transformer of a class AB push-pull amplifier has the duty to

tightly couple the drains, and at the same time bring in the power

supply in a way that allows the huge second harmonic supply current

ripple to go through to the bypass capacitors. It needs to have

extremely low leakage inductance, and the circuit it works in, which

includes the transistors, the bypass caps, and all their

interconnections, including the path through ground, must also

have extremely low stray inductance. A class AB linear amplifier of

this kind works well in the frequency range where these leakage and

stray inductances are negligible. At higher frequencies these

inductances cause trouble, making the amplifier's performance degrade.

The

feed transformer of a class AB push-pull amplifier has the duty to

tightly couple the drains, and at the same time bring in the power

supply in a way that allows the huge second harmonic supply current

ripple to go through to the bypass capacitors. It needs to have

extremely low leakage inductance, and the circuit it works in, which

includes the transistors, the bypass caps, and all their

interconnections, including the path through ground, must also

have extremely low stray inductance. A class AB linear amplifier of

this kind works well in the frequency range where these leakage and

stray inductances are negligible. At higher frequencies these

inductances cause trouble, making the amplifier's performance degrade.

Many people have used bifiliar

chokes using several turns of two parallel wires wound on toroidal

cores. Those do not work!!! Or rather, they do bring in the DC just

fine, of course, and being bifiliarly wound they benefit from DC

cancellation, which keeps them from saturating - but that's all. They

don't couple the drains, because their leakage inductance is far too

high. In that regard they work almost exactly like two separate feed

chokes. My amplifier instead attempts to demonstrate the advantages of

getting this point as correct as possible.

To this end I picked the smallest ferrite core that can just barely

handle the voltage at low enough loss on the lowest band (160m), and

that provides just barely enough inductance on that band. A good choice

of core material, size and shape is required. Unfortunately the choice

of ferrite materials a private experimenter can obtain is extremely

limited. Among the cores I can get, the Amidon BN-61-202 was the most

promising.

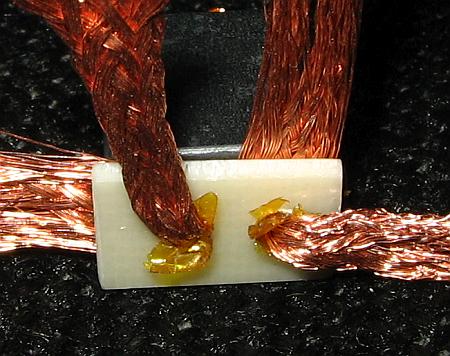

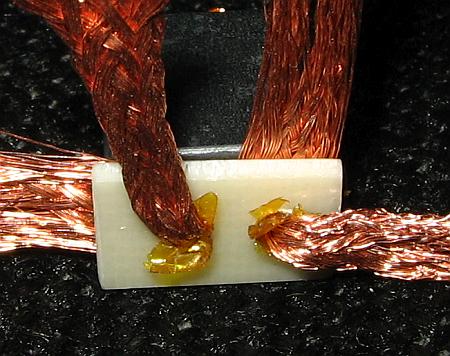

I wound this core with a single turn of homemade extra low impedance

coax cable. The point here is getting the insulation so thin that the

two conductors end up very close together, minimizing leakage

inductance. I used braid from a good quality RG-58 cable, wrapped one

piece of that braid in a spiral winding of kapton tape, wound with such

an overlay as to get two layers of tape covering the conductor.

Then

I slipped another piece of identical braid over it, and wrapped it in

kapton tape just to keep that braid in close contact with the

insulation.

The

outer braid ends were bent to the sides, and the inner ones were

threaded through the holes drilled into a piece of copper-free PCB

material, used as insulating separator. The kapton wrap goes along into

the holes, to maintain integrity of insulation, and then was cut.

The

outer braid ends were bent to the sides, and the inner ones were

threaded through the holes drilled into a piece of copper-free PCB

material, used as insulating separator. The kapton wrap goes along into

the holes, to maintain integrity of insulation, and then was cut.

This

is the somewhat uncombed feed transformer, ready for installation. My

idea was that after soldering the three coax loops of the output

transformer flat to the drain pad, I would solder the very short feed

transformer terminals to the top side of those coax cables, and bend

the feed transformer side terminals down to the bypass capacitors,

fanning them out to minimize inductance, and solder them. The core

would stand vertically over the drain pad area.

This

is the somewhat uncombed feed transformer, ready for installation. My

idea was that after soldering the three coax loops of the output

transformer flat to the drain pad, I would solder the very short feed

transformer terminals to the top side of those coax cables, and bend

the feed transformer side terminals down to the bypass capacitors,

fanning them out to minimize inductance, and solder them. The core

would stand vertically over the drain pad area.

As

happens so often, practice ended up differing somewhat from theory. My

rat had left rather little space there, and my old eyes and hands had

made a mess with the transformer connections, so that I had to change

plans and install the feed transformer in the best way I found at that

point. It ended up roughly horizontal over the LDMOSFET, with much

longer supply terminals than I intended. There are several

nanohenries of stray inductance here, which weren't planned. Just the

feed transformer's terminal inductance is surely much larger

than its leakage inductance. Those two act in series and are

equally undesirable.

As

happens so often, practice ended up differing somewhat from theory. My

rat had left rather little space there, and my old eyes and hands had

made a mess with the transformer connections, so that I had to change

plans and install the feed transformer in the best way I found at that

point. It ended up roughly horizontal over the LDMOSFET, with much

longer supply terminals than I intended. There are several

nanohenries of stray inductance here, which weren't planned. Just the

feed transformer's terminal inductance is surely much larger

than its leakage inductance. Those two act in series and are

equally undesirable.

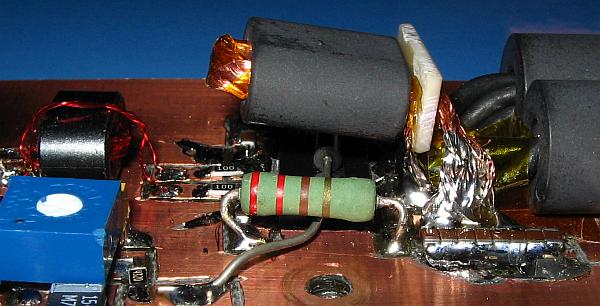

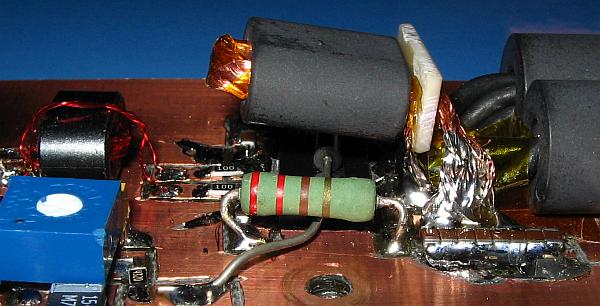

Note that in this photo you can see the temperature sensing diode lying

on the LDMOSFET, and the drive transformer is in place. The gate

shorting jumpers have been removed.

The 3W feedback resistors are far larger than necessary. 1W would have

been just big enough, but I had none. I found these big 220Ω resistors

on old CRT TV boards. Two separate TVs, so the two resistors aren't

identical, but they are of the same value, type and size!

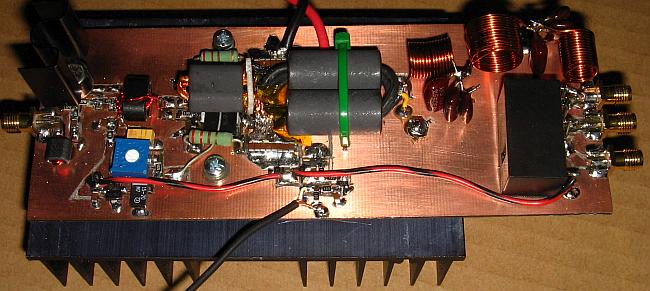

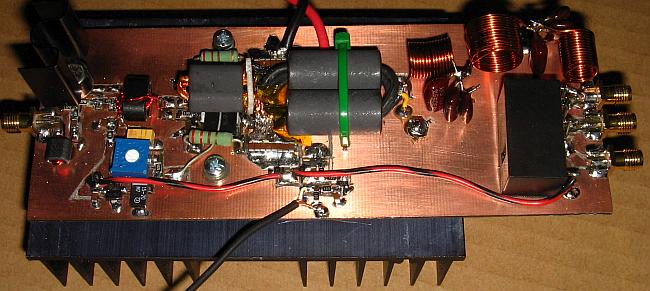

After

some more board gnawing, building the TX/RX switching circuit, the low

pass filter, installing the relay and

the

output-side connectors, and bolting the whole thing to a heatsink, it

looked like this. You can click this photo to get a larger version and

see the amplifier in its full glory.

After

some more board gnawing, building the TX/RX switching circuit, the low

pass filter, installing the relay and

the

output-side connectors, and bolting the whole thing to a heatsink, it

looked like this. You can click this photo to get a larger version and

see the amplifier in its full glory.

The relay I used is far larger than necessary for this low power. It comes from the parts

I bought for the legal-limit power project.

Here

is a view that shows the spreader between the heatsink and the

board. The heatsink measures 120×75×30mm, and during ragchewing at full

power it gets just lukewarm. Without needing a fan, of course. During long

term key-down testing it gets somewhat warmer, but not a lot.

Here

is a view that shows the spreader between the heatsink and the

board. The heatsink measures 120×75×30mm, and during ragchewing at full

power it gets just lukewarm. Without needing a fan, of course. During long

term key-down testing it gets somewhat warmer, but not a lot.

The copper foil connecting the bypass caps to the underside foil ends

up sandwiched between the board and the heat spreader. For that reason

the board doesn't sit exactly parallel to the heatsink. Its output side sits

higher than the input side. The solder fills out the resulting space

between the board and the spreader.

Given the stiffness of this board, no additional support was fond

necessary. It's attached to the heatsink just by the two screws.

There are no connections on the underside of the board. It's just a

continuous groundplane joined to the upper side groundplane only at the

connectors and through the two copper tape straps. Some more

interconnections might improve performance on the high bands.

Performance measurements

I used digital multimeters to measure the supply voltage and current. A

Tektronix 485 oscilloscope with either direct 50Ω connection through

attenuators, or using low impedance Z0 probes having over 500MHz bandwidth, to see the waveforms and

to measure the output power. And the spectral display of PowerSDR,

derived through receiver #2 from the feedback voltage divider, to

assess linearity through IMD measurement. The software's adaptive

predistortion amplifier analyzer was used to separately measure and

graph amplitude and phase linearity. The 50Ω dummy load used is a Bird

unit rated up to UHF.

All measurement results are for the complete amplifier, including the

driver stage. The driver, relay, switching circuit and bias circuit

draw a total of 120mA, so that the current in the final stage is always 0.12A lower

than the total current.

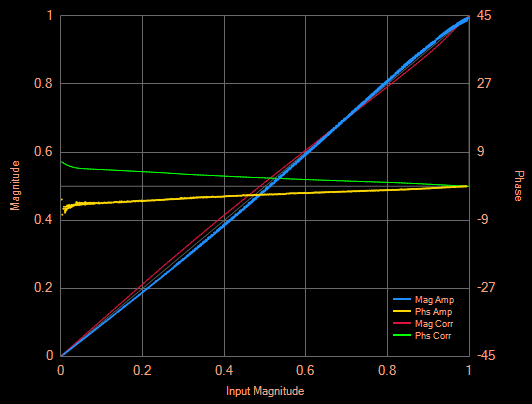

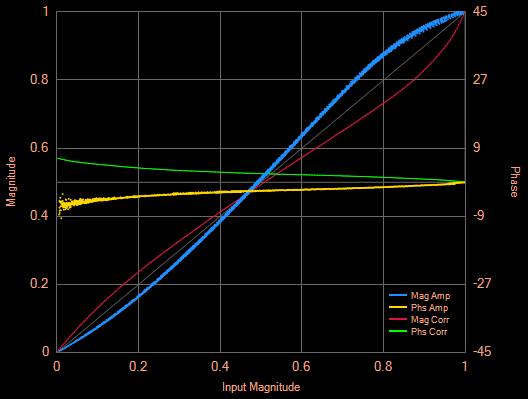

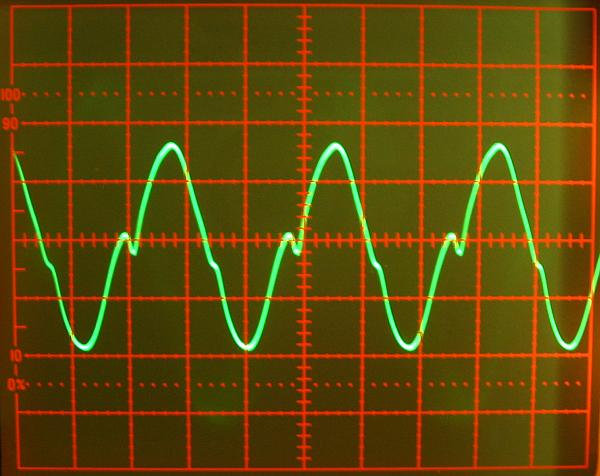

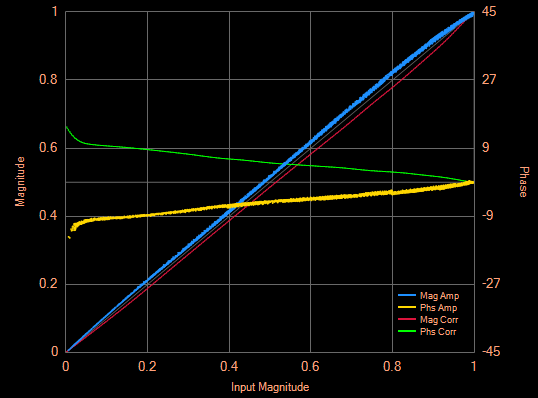

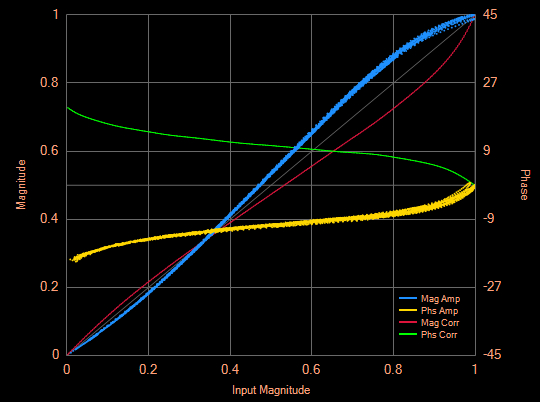

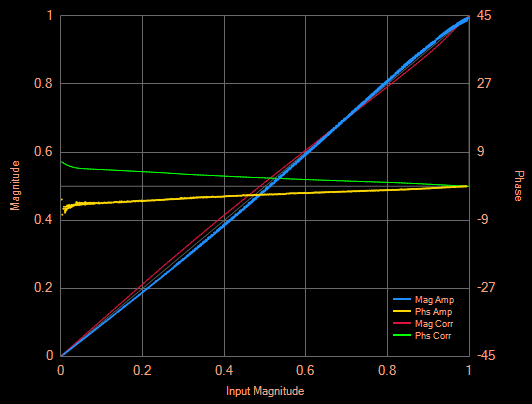

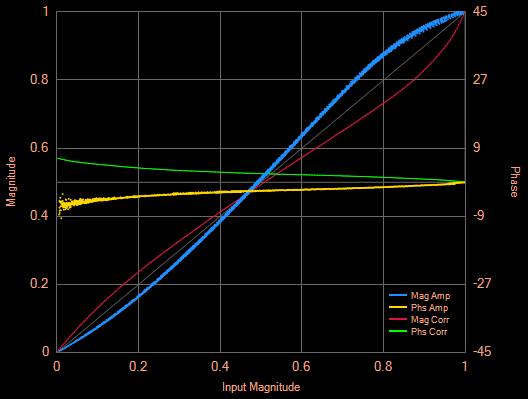

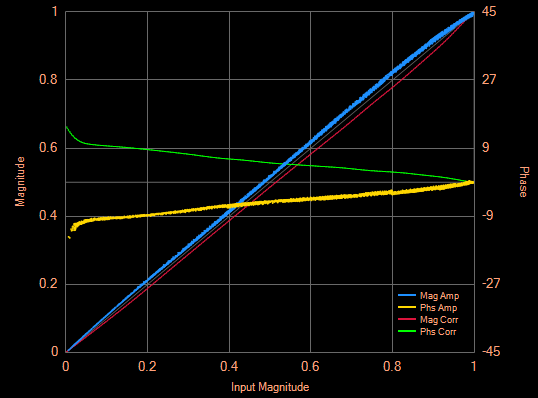

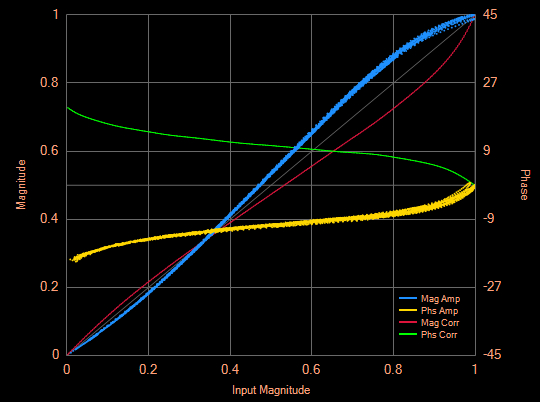

On the 40m band, using

the 40m lowpass filter, a 13.8V

supply, and with the bias set for 1.12A total current at no drive (1A

in the final stage), the amplifier just begins compressing the gain at

50W output. These curves show the amplifier's response under these

conditions. The blue curve is the amplitude response, and the yellow

curve shows the phase response. The other two curves are the

compliments to them, and show the corrections that the adaptive

predistortion system will apply if switched on.

On the 40m band, using

the 40m lowpass filter, a 13.8V

supply, and with the bias set for 1.12A total current at no drive (1A

in the final stage), the amplifier just begins compressing the gain at

50W output. These curves show the amplifier's response under these

conditions. The blue curve is the amplitude response, and the yellow

curve shows the phase response. The other two curves are the

compliments to them, and show the corrections that the adaptive

predistortion system will apply if switched on.

As you can see, the gain curve is quite linear, but not perfectly so,

showing lowest gain at about one third of the maximum amplitude, and

highest gain at a little less than full power. This sort of distortion

is inevitable, given that MOSFETs are square-law devices, rather than

linear ones. We could eliminate the slight nonlinearity at the high end

of the drive range, by limiting the amplifier to 45W, or by slightly

increasing the supply voltage, but the distortion in the low power

range is simply a fact of life. We can reduce it, by further increasing

the bias and by using even stronger negative feedback, but never

eliminate it.

The phase response shows roughly 6° phase shift between low power

and maximum. This comes mostly from the voltage-variable capacitances

all transistors have, and we cannot do much about it except choosing

transistors that have low capacitances, which I did.

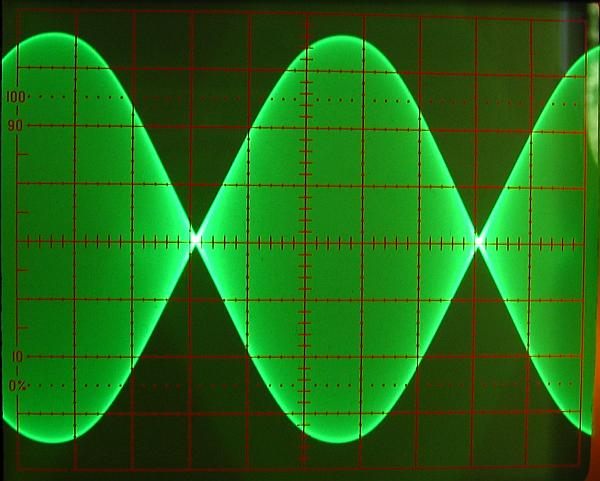

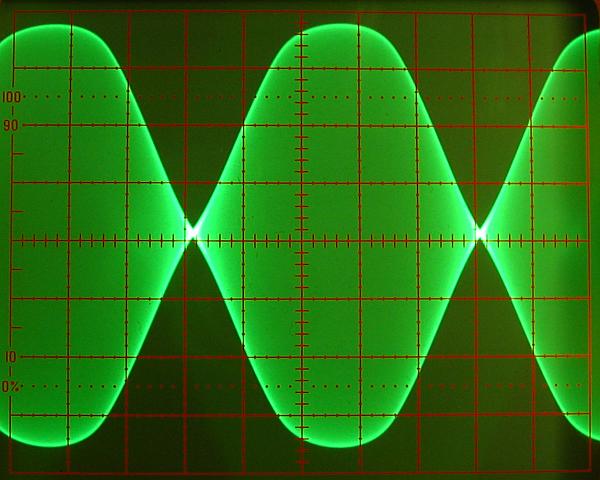

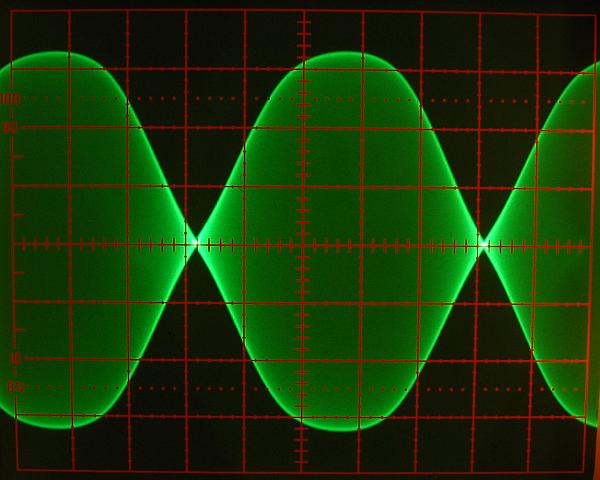

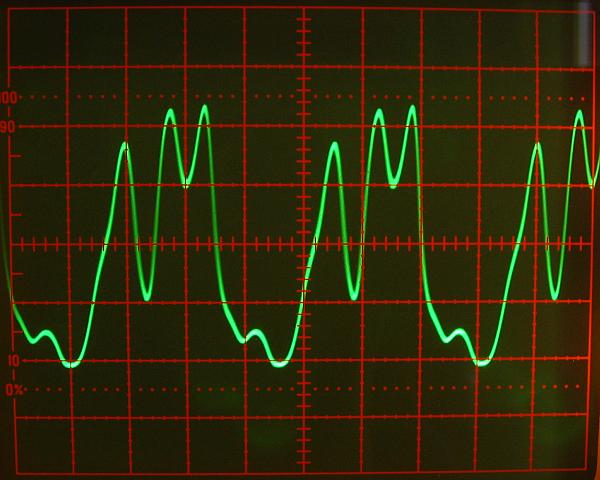

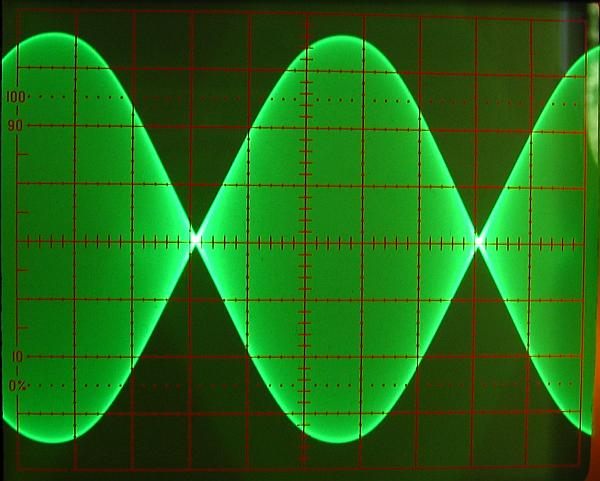

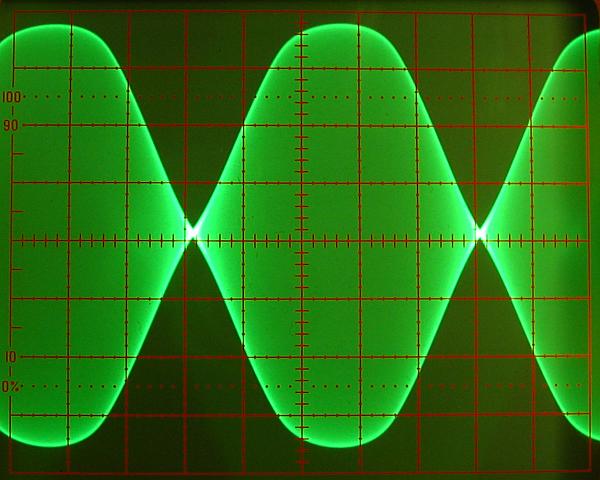

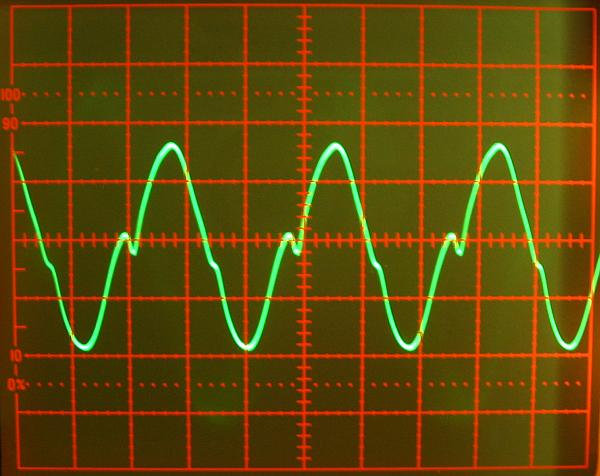

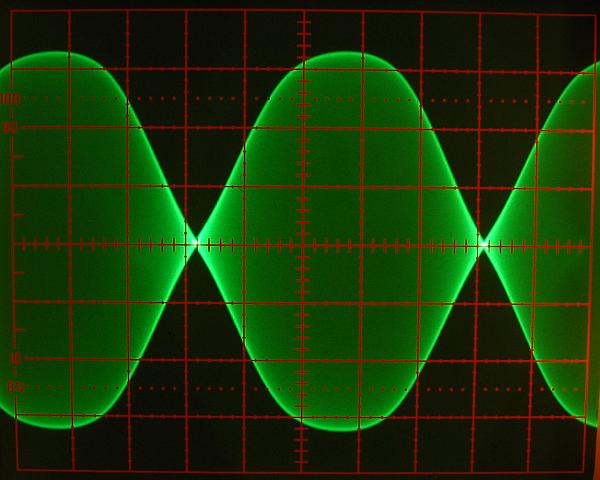

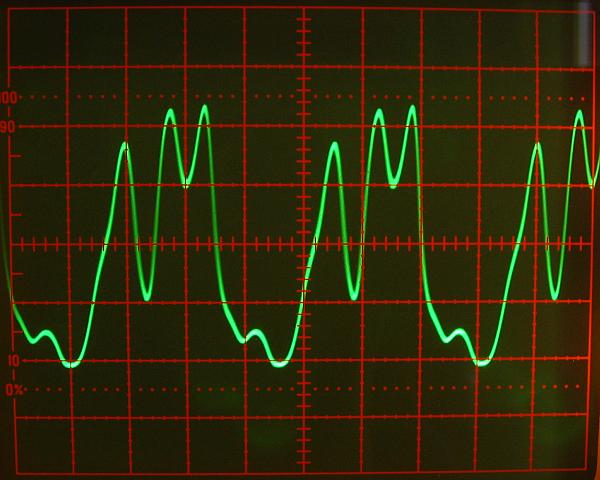

The

two-tone signal looks pretty clean and nice on the scope screen. It

would take a very well trained eye to detect the slight amplitude

distortion of this amplifier on the scope! And of course the

scope can't show the phase distortion at all.

The

two-tone signal looks pretty clean and nice on the scope screen. It

would take a very well trained eye to detect the slight amplitude

distortion of this amplifier on the scope! And of course the

scope can't show the phase distortion at all.

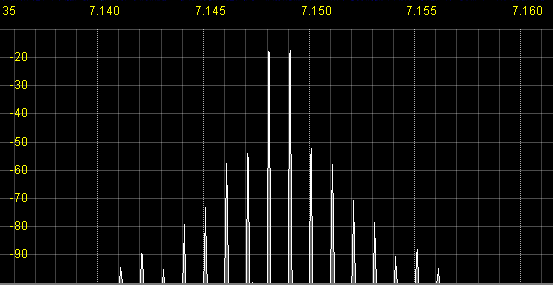

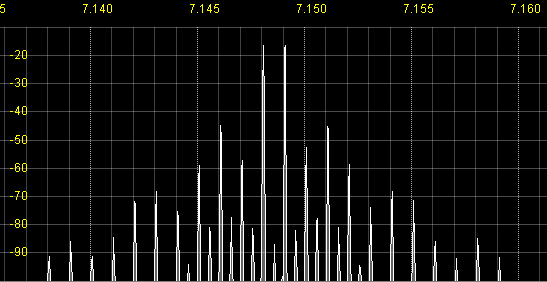

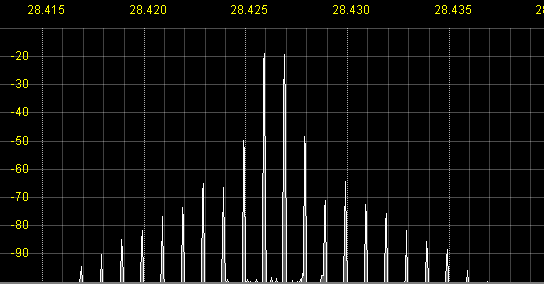

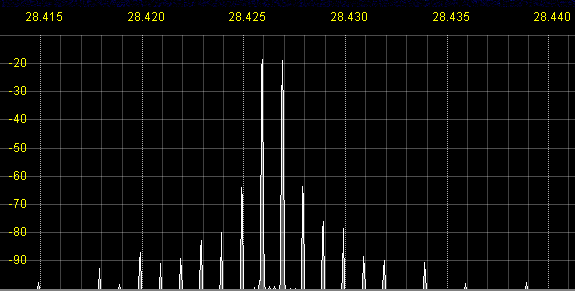

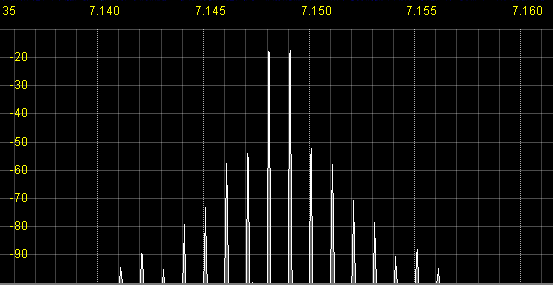

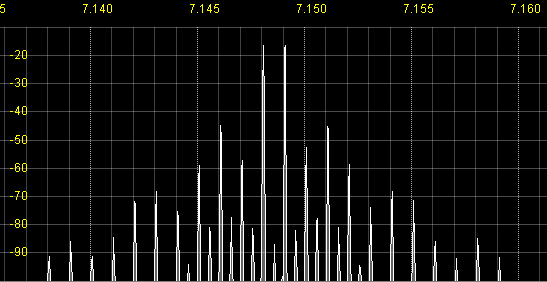

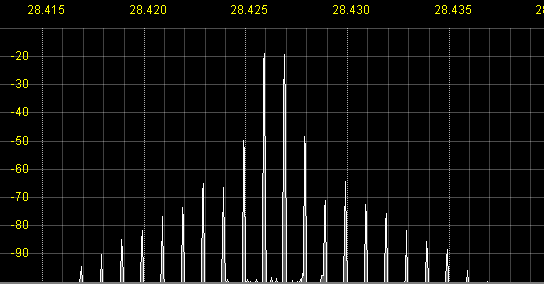

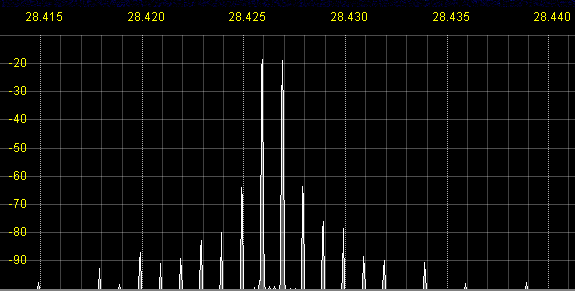

The

spectrum analyzer is the best tool to assess linearity. You can see

that the third order intermodulation products are roughly 34 or 35dB

below the individual tones, which means that they are 40 to 41dB below

the PEP output. This is much better than what many commercial

transceivers achieve!

The

spectrum analyzer is the best tool to assess linearity. You can see

that the third order intermodulation products are roughly 34 or 35dB

below the individual tones, which means that they are 40 to 41dB below

the PEP output. This is much better than what many commercial

transceivers achieve!

The 5th order IMD is only slightly lower, but the higher IMD products

fall off in strength rather quickly.

Operating under these conditions, the complete amplifier draws 3.74A.

At 50W single tone (carrier) output, it draws 5.57A. That's a

single-tone efficiency of 65% for the entire amplifier, including the

driver and switching, or 66.5% for the final stage alone.

The theoretical limit for pure class B amplifiers is 78.5%, but in real

amplifiers it's always lower due to imperfect saturation of

the

transistors, and various other losses. Class AB further reduces the

efficiency. So the efficiency this little amplifier is producing is

probably as good as one could hope for!

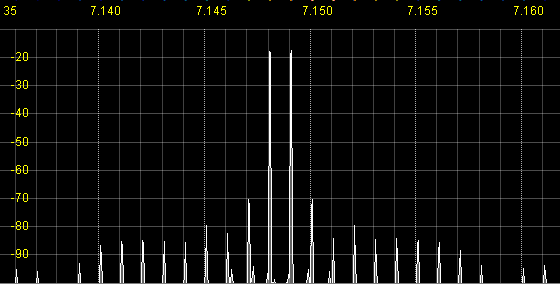

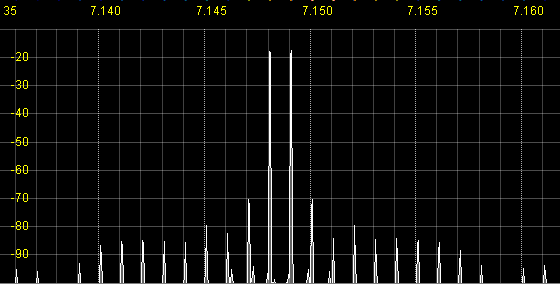

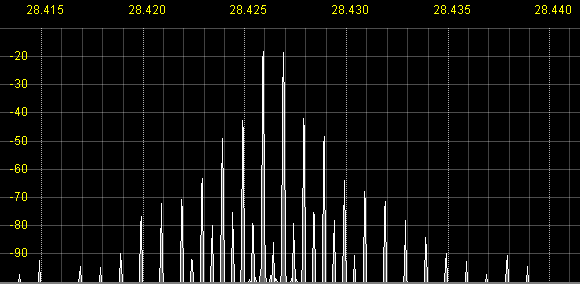

Although

this amplifier is plenty clean enough to put it on the air without any

digital tricks, there is no reason why I shouldn't use some of the

trickery offered by modern digital signal processing. Among these is

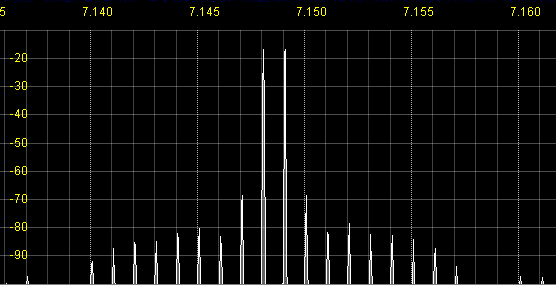

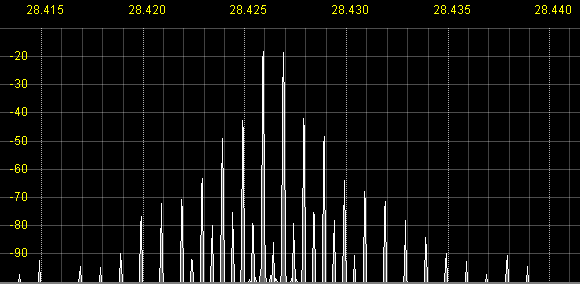

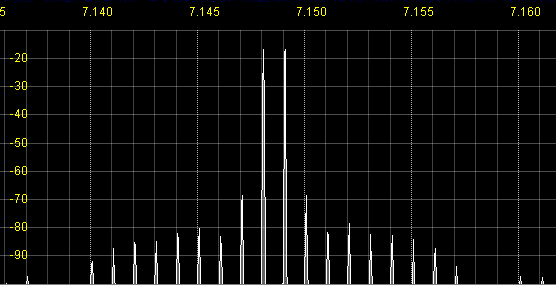

adaptive predistortion. Switching it on makes the 3rd IMD plummet to

53dB below each tone, 59dB below PEP, and all other IMD products are at

least a further 10dB down! The PEP output increases in a barely

noticeable way, and the total supply current increases

marginally

to 3.79A.

Although

this amplifier is plenty clean enough to put it on the air without any

digital tricks, there is no reason why I shouldn't use some of the

trickery offered by modern digital signal processing. Among these is

adaptive predistortion. Switching it on makes the 3rd IMD plummet to

53dB below each tone, 59dB below PEP, and all other IMD products are at

least a further 10dB down! The PEP output increases in a barely

noticeable way, and the total supply current increases

marginally

to 3.79A.

Not all IMD products shrink, though. The more remote ones, starting at

with the 11th, actually increase in strength, compared to the

non-predistorted result. This is a typical side-effect of predistortion

in digital processing, caused mainly by the limited bandwidth

over

which the predistortion system analyzes and corrects the amplifier's nonlinearities. But with all

these rogue IMD products being much more than 60dB below PEP, it's a

non-issue in most practical ham applications.

Having

the adaptive predistortion system at my disposal, it's of course

tempting to improve the amplifier's efficiency and output

power, worsening its linearity in the process, and then fix up

the

linearity through that digital magic. To try this, I reduced the bias

setting to get only 0.5A total current draw at no signal, meaning 380mA

idling current in the final stage, and then driving it more strongly, all

the way into pretty deep gain compression.

Having

the adaptive predistortion system at my disposal, it's of course

tempting to improve the amplifier's efficiency and output

power, worsening its linearity in the process, and then fix up

the

linearity through that digital magic. To try this, I reduced the bias

setting to get only 0.5A total current draw at no signal, meaning 380mA

idling current in the final stage, and then driving it more strongly, all

the way into pretty deep gain compression.

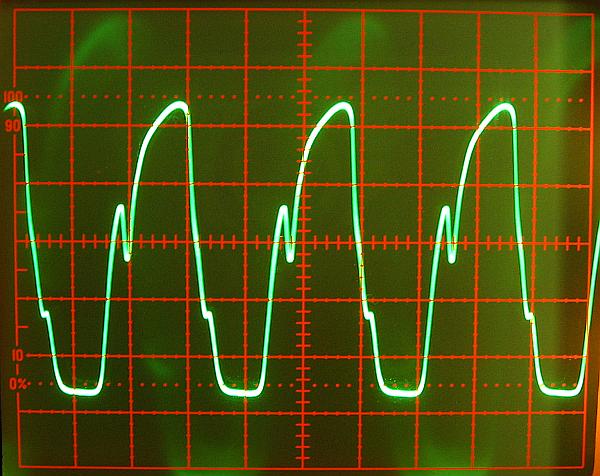

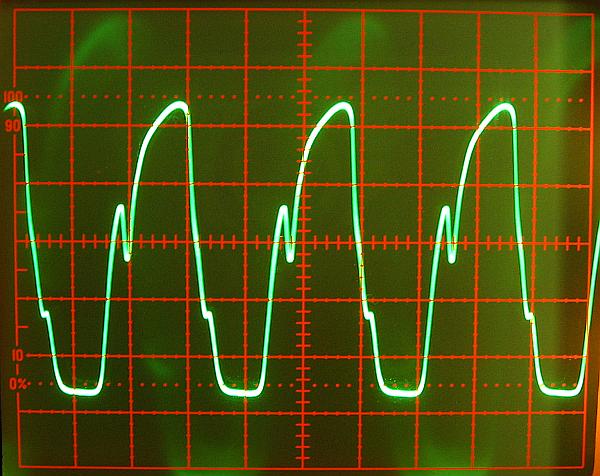

This being a clean class AB push-pull amplifier, which clips the output

voltage when overdriven, the gain compression is rather hard and abrupt, so there

is only a modest amount of power to be gained by operation in saturation. I got 61W output while

operating the amplifier in this way.

The gain curve shows strong compression at high power, and rather

severe crossover distortion caused by the low bias. The phase response curve instead doesn't

change much, there is just a little more phase change in the saturation

region, caused by the drains getting closer to ground potential for a

larger portion of the RF cycle. At lowest drain voltage the capacitance

modulation is greatest.

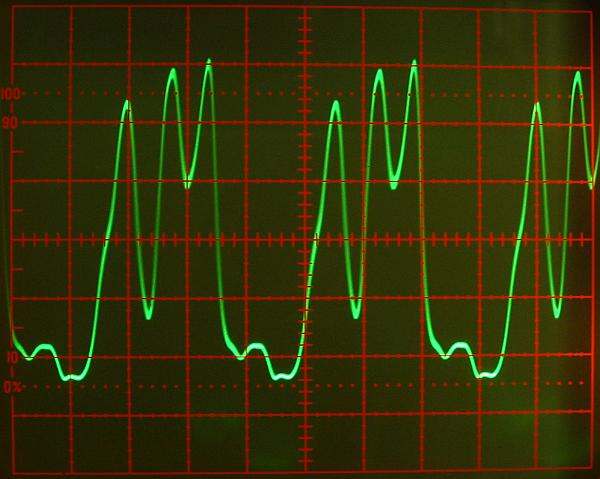

The

waveform on the scope screen shows both the crossover distortion and the

flat-topping in a very obvious way. It's easy to see the distorted

amplitude response curve modulating the sine envelope!

The

waveform on the scope screen shows both the crossover distortion and the

flat-topping in a very obvious way. It's easy to see the distorted

amplitude response curve modulating the sine envelope!

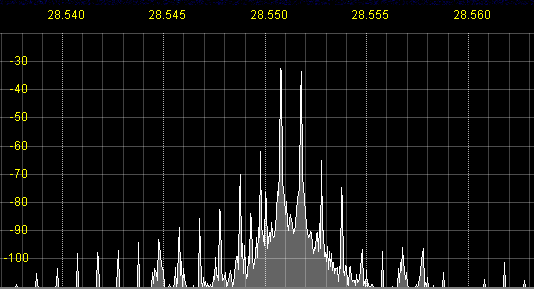

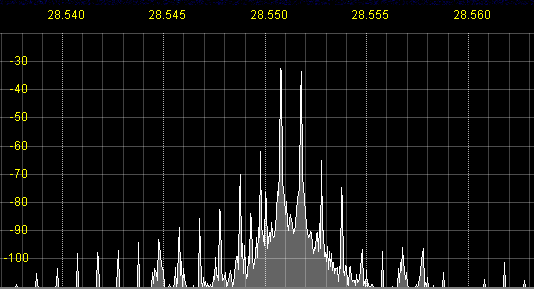

How dirty is such a signal?

The spectrum

analyzer provides the answer: Much more dirty! But plenty good enough

for some people...

The spectrum

analyzer provides the answer: Much more dirty! But plenty good enough

for some people...

The 5th IMD ends up larger than the 3rd one, at about 28dB below each

tone. Sneaky specmen wanting to sell an amplifer that normally works

like this might proudly tell you that the 3rd IMD is 35dB down,

without telling you that the 5th IMD is only 28dB down!

Most manufacturers are fully satisfied with such a result, and

many commercially available transceivers cannot do better

than this when driven to their full output! Specially at lower than normal supply voltage.

Using

PowerSDR, I can. You can too, if you use it. Switching on the adaptive

predistortion pushes the IMD products down where they belong! The

3rd IMD is down about 52dB below each tone, barely 1dB worse

than

at 50W with high bias!

Using

PowerSDR, I can. You can too, if you use it. Switching on the adaptive

predistortion pushes the IMD products down where they belong! The

3rd IMD is down about 52dB below each tone, barely 1dB worse

than

at 50W with high bias!

Operating like this, with predistortion, the amplifier produces a very

clean 61W signal, while consuming 4.03A during 2-tone transmission,

and 5.97A when transmitting a single tone (carrier). And

that,

dear folks, is 74% overall efficiency, including the driver stage,

relay and switching circuit! Or 75.6% if we only measure the final

stage's current drain, but I won't put my hand on fire for the

decimals, given that I'm measuring the power on a scope screen.

Although my scope is of high quality, very well calibrated, and

produces a nice sharp trace, analog measurement has its

limits...

Getting ~75% efficiency from a very simple class AB amplifier, along

with a very clean signal, is strong advertising for adaptive

predistortion and for clean amplifier design.

I tried to go further, by turning down the bias even lower, driving the

amplifier even harder, and letting the adaptive predistortion clean up

the resulting mess. But the results were not so nice, because the low

bias made the far-out IMD products rise, and these are out of the

control of the bandwidth-limited adaptive predistortion system. It can

do magic only up to a point... So I concluded that

operating the amplifier like shown here, at slightly over 60W and with

0.5A total current at zero signal, and using adaptive predistortion, is

about best. And for people who don't have a signal generating system

that includes adaptive predistortion, I suggest to keep the bias

setting at about 1.1 to 1.3A total current at no signal, and limit the

output power to 50W.

Nothing had been said so far about harmonics, because thanks to the use

of a decent lowpass filter they aren't an issue. But I quickly measured

them. Running the amplifier at 61W output, the second harmonic is 54dB

down from the fundamental, the third one is 63dB down, the fourth is

77dB down, and the fifth is 74dB down. Push-pull amplifiers suppress

self-generated even harmonics, if they are well balanced, but

of

course they happily amplify any harmonic that might be present in the

driving signal! And my driver stage is single-ended, so the second

harmonic is its strongest. Also the Red Pitaya might have some significant harmonic

contents in its output. These are the reasons why the second harmonic

is the strongest by far. Combined with the fact, of course, that

lowpass filters attenuate higher harmonics more strongly.

If some stringent application would require stronger suppression of the

second harmonic, I would try a push-pull driver stage.

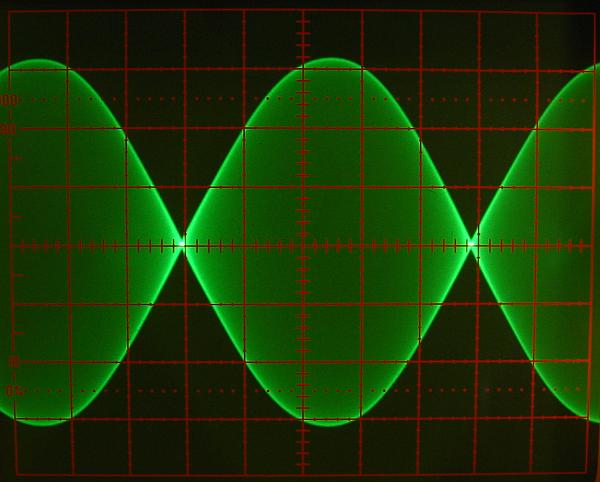

In

broadband RF amplifiers the voltage waveform at the drain usually

reveals such severe imperfections that many builders prefer not looking

at it! Since I seem to have masochist inclinations, at least in the

realm of electronics, I do.

In

broadband RF amplifiers the voltage waveform at the drain usually

reveals such severe imperfections that many builders prefer not looking

at it! Since I seem to have masochist inclinations, at least in the

realm of electronics, I do.

At roughly 20W output power, it looks as shown here. The vertical scale

is 5V/div, and the screen center is at the 13.8V supply voltage. As you

can see, the waveform closely resembles a sine wave, except for

a wiggle at zero-crossing time, when the transistor is ceasing

conduction. This is caused by the non-zero leakage and stray

inductance in the feed transformer and associated circuit. As much as I

tried to reduce these unwanted inductances, a few tens of nanohenry

remain, and at the low drain load of just around 1.4Ω on the active

side, that's bad enough.

Even with this wiggle, this waveform is much better than what you will

see in many other push-pull amplifiers.

At 61W

output the amplifier is strongly saturated. You can see the LDMOSFET

pulling its drain very close to ground, roughly 0.5V (remember that the

center line is 13.8V and scale is 5V/div).

At 61W

output the amplifier is strongly saturated. You can see the LDMOSFET

pulling its drain very close to ground, roughly 0.5V (remember that the

center line is 13.8V and scale is 5V/div).

The wiggle is still present and larger, due to the higher drain

current.

It can also be seen that coupling between the drains is present

but

far from perfect. If it was perfect, the waveform would be symmetrical.

But the top of the waveform shows a ramp instead of a horizontal line

while the opposite transistor holds its drain to ground, which

again is caused

by the stray and leakage inductances. At least the coupling is good

enough to totally avoid voltage overshoot. The peak drain voltage is

a little less than twice the supply voltage, exactly like it should be

in a class AB amplifier.

And since leakage inductance is uncoupled between the sides, the wiggle

of one side doesn't transfer to the other. Instead there is a separate,

smaller wiggle on the downgoing slope, caused by the rising drain

current and the leakage inductance.

In the spectral domain these wiggles appear as harmonics, and are

rejected pretty well by the lowpass filter.

So my lovingly crafted feed transformer and my carefully

designed

very low inductance ground return are still bad enough to cause

obviously imperfect drain-to-drain coupling even on 40 meters! While the

7MHz fundamental is well coupled, the harmonics aren't. On higher bands

this can only get worse.

I did much testing on 40m for three reasons: Because the 40m band is

the geometric center of this amplifier's intended bandwidth, being a

factor 4 above the 160m band and the same factor 4 below the

10m

band; Also because it's the band I use most; But mainly

because I

had the 40m lowpass filter installed on the board when I started

doing systematic tests!

Of course it's essential to see how the amplifier behaves on the other

bands. To avoid having to build a lot of lowpass filters, and

to

abstain from doing measurements without a lowpass filter in place,

which are essentially meaningless because harmonic power masquerades as

useful power and the amplifier operates under totally abnormal

conditions, I built a lowpass filter for 10m,

just for testing.

Of course it's essential to see how the amplifier behaves on the other

bands. To avoid having to build a lot of lowpass filters, and

to

abstain from doing measurements without a lowpass filter in place,

which are essentially meaningless because harmonic power masquerades as

useful power and the amplifier operates under totally abnormal

conditions, I built a lowpass filter for 10m,

just for testing.

The leakage inductance of the output transformer, plus the stray inductance of

the connections between the transformer and the LDMOSFET, are low

enough to be negligible on the 40m band. But not so on 10m! I measured

the leakage+stray inductance by connecting my NanoVNA to the secondary

side of the transformer, while placing a short between the drains,

directly at the FET's body. It came out as 68nH. That's pretty good,

and with proper compensation would allow using this transformer up to

about 100MHz. Compensation is really easy when using a T-configured

lowpass filter, because all that has to be done is subtracting the

leakage+stray inductance from the exact inductance calculated for the

input coil of the filter! With my choices of cutoff frequency and

bandpass ripple I ended up needing 236nH for the filter's

input

inductor without compensation, so I made that inductor to have 168nH,

to compensate for the leakage+stray of the amplifier's output section.

I wound the coils to give a little more than the exact needed

inductance when close-wound, and then stretched them out a little while

measuring their inductances, to get the exact values.

I left the capacitor groups of the 40m filter in place, just removing

its coils, and built the 10m filter around them. Laziness rules.

These

are the amplifier's gain and phase curves on 10m, operating in linear

mode, with 1A idling current in the final stage, and driven to the

point where gain compression starts. At this point it delivers 40W

output.

These

are the amplifier's gain and phase curves on 10m, operating in linear

mode, with 1A idling current in the final stage, and driven to the

point where gain compression starts. At this point it delivers 40W

output.

The amplitude linearity curve is different but not much worse than on 40m. The

phase response instead is significantly worse than on 40m. This is an

inevitable result of the voltage-variable capacitances in

semiconductors having more effect at higher frequencies.

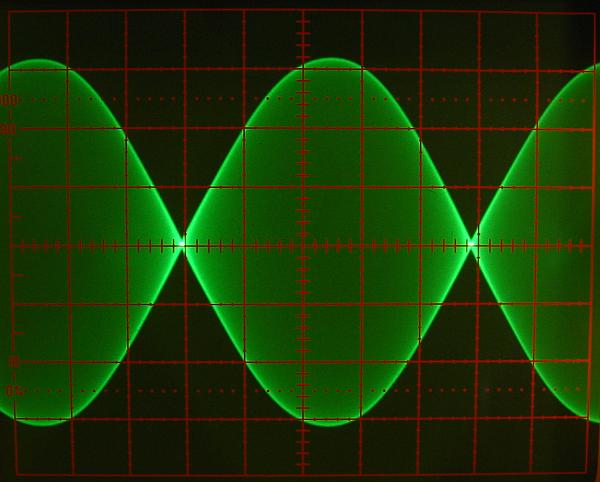

The

two-tone waveform looks pretty good, since it cannot show phase

distortion. Judging SSB signal quality purely from such a scope display

is misleading, for this reason.

The

two-tone waveform looks pretty good, since it cannot show phase

distortion. Judging SSB signal quality purely from such a scope display

is misleading, for this reason.

Vertical scale is the same as in the 40m tests. The power difference

between the bands is clearly visible. Slightly lower voltage, meaning significantly lower power.

Without

using any sort of correction, the 3rd IMD products are 30dB down from

the individual tones, 36dB down from PEP. That's about 4 to 5dB worse

than on 40m, but still pretty good. The higher order IMD products fall

off at a slower rate than on 40m, probably mostly an effect of the

phase distortion.

Without

using any sort of correction, the 3rd IMD products are 30dB down from

the individual tones, 36dB down from PEP. That's about 4 to 5dB worse

than on 40m, but still pretty good. The higher order IMD products fall

off at a slower rate than on 40m, probably mostly an effect of the

phase distortion.

Under these conditions the amplifier consumes 4.38A with a two-signal,

and 6.65A with a single tone. That equates to 43.6% efficiency

including the driver stage, a much worse result than the 65% achieved

on 40m in linear operation.

Enabling

the adaptive predistorstion system cleans up the amplifier to a high

quality, pushing the 3rd IMD down about 46dB below each tone. Again,

not as good as the 53dB obtained on 40m.

Enabling

the adaptive predistorstion system cleans up the amplifier to a high

quality, pushing the 3rd IMD down about 46dB below each tone. Again,

not as good as the 53dB obtained on 40m.

Reducing

the bias to obtain 0.5A total current drain at zero signal, 380mA in

the final stage, and increasing the drive into stronger saturation,

these are the response curves obtained. The amplitude distortion is

quite similar to the 40m case, only the curve is noticeably noisier. I

don't know how much of this comes from memory effects in the amplifier,

and how much is actual noise, derived from the fewer samples per RF

cycle that the Red Pitaya has to work with, on the higher frequency.

Reducing

the bias to obtain 0.5A total current drain at zero signal, 380mA in

the final stage, and increasing the drive into stronger saturation,

these are the response curves obtained. The amplitude distortion is

quite similar to the 40m case, only the curve is noticeably noisier. I

don't know how much of this comes from memory effects in the amplifier,

and how much is actual noise, derived from the fewer samples per RF

cycle that the Red Pitaya has to work with, on the higher frequency.

The phase distortion also increases, and its trace also looks noisier.

No

news here, the scope pattern shows the deformation that are

caused

by the amplitude nonlinearity reported in the blue curve above.

No

news here, the scope pattern shows the deformation that are

caused

by the amplitude nonlinearity reported in the blue curve above.

The

uncorrected signal produced in this way is of course quite dirty: The

3rd IMD is only 23 or 24dB below each tone! This is too dirty to put on

the air without being ashamed.

The

uncorrected signal produced in this way is of course quite dirty: The

3rd IMD is only 23 or 24dB below each tone! This is too dirty to put on

the air without being ashamed.

Digital

magic to the rescue! With predistortion enabled, the 3rd IMD is again

46dB or so below each tone, an excellent signal quality.

Digital

magic to the rescue! With predistortion enabled, the 3rd IMD is again

46dB or so below each tone, an excellent signal quality.

Under these conditions the amplifier delivers 44W PEP, consuming 4.26A.

Transmitting a single tone it consumes 6.69A, giving 47.7%

efficiency including the driver stage. Poor, but usual for solid state

amplifiers operating at the high end of their frequency range.

The

RF voltage waveform at one drain shows why we are getting less power,

more amplitude distortion and much lower efficiency on 10m.

The

RF voltage waveform at one drain shows why we are getting less power,

more amplitude distortion and much lower efficiency on 10m.

This trace was shot with the low bias setting and at a drive level

where the FETs don't saturate. The center line is at the

13.8V supply voltage, scale is 5V/div. The zero-crossing

wiggle

caused by leakage inductance in the feed transformer and connections

has grown to an enormous size, due to the much faster current slew rate

at the higher frequency.

Also an inversion of the positive peak appears, which is another

telltale sign of leakage inductance in the feed transformer. The

amplifier is being current-starved at the signal peaks, due to leakage

inductance acting as a choke in series with the supply, after the

bypass caps.

In

saturated operation we can see that the drain voltage gets pulled down

to about -12V from the supply, meaning about 1.8V drain saturation

voltage. The drain-source capacitance, which gets large at low drain

voltage, has a stronger limiting effect than on 40m. So does the

reverse transfer capacitance of the FETs. This reduced amplitude,

combined with the

very distorted waveform, which contains less fundamental energy, is the

cause why the amplifier delivers so much less power on 10m than on 40m,

even in

saturation.

In

saturated operation we can see that the drain voltage gets pulled down

to about -12V from the supply, meaning about 1.8V drain saturation

voltage. The drain-source capacitance, which gets large at low drain

voltage, has a stronger limiting effect than on 40m. So does the

reverse transfer capacitance of the FETs. This reduced amplitude,

combined with the

very distorted waveform, which contains less fundamental energy, is the

cause why the amplifier delivers so much less power on 10m than on 40m,

even in

saturation.

How could this be improved?

If we could buy better magnetic cores, that have higher permeability

along with low loss at high flux density, we could use them to make an almost

microscopically small feed transformer, that has very low leakage

inductance. This could be embedded right over or under the LDMOSFET

drain tabs, with minimal-length and maximal-width bypass capacitors

and connections to the MOSFET source. But since such a good magnetic material

doesn't exist yet, as far as I know, this remains a purely theoretical

solution.

Many manufacturers and experimenters have done away completely with

the feed transformer, living with totally uncoupled drains, thus

running their amplifiers in a class AB-D hybrid mode. This can work

well if square wave drive is used, but that requires additional care in

the driver stage. All practical implementations of this sort that I

have tested, have ended up showing equal or worse performance than my

little amplifier - and on all bands, not just at the high end of their

frequency ranges! My amplifier at least is good on the lower bands...

Using a higher supply voltage improves the situation. For example at 4 times higher

voltage, and the same power, 4 times as much ferrite cross-section is

needed, thus the feed transformer will have twice the wire length and twice the leakage

inductance, if built in the same style. But the drain load resistance

will be 16 times as high, making us end up with a situation that is 8

times better! In addition the stray inductance in the connections will

probably remain the same, and so the final result will be more than 8

times better. It smells like a good solution. The problem is that RF

power transistors for higher voltages suffer much more from

internal capacitances. Phase distortion can be really bad with them, and the

very existence of those high capacitances, relative to load impedance,

also causes some trouble in getting good efficiency.

Other bands:

I was too lazy to build more lowpass filters, so I tested 20 to 12

meters using the 10m filter, and 160 and 80 using the 40m

filter. For that reason I prefer not publishing detailed per-band test

results, as they would be slightly differenet from what would be

obtained with the correct filters for each band.

But there were no surprises during this testing. The efficiency is a

tad better on 80m than on 40m, while on 160m it gets down again to the

40m value, as the feed transformer starts showing that its inductance

isn't sky-high. Linearity also shows a general trend to be best on the

lowest

bands, caused by the phase distortion being larger at higher

frequencies. Using adaptive predistortion, the signal quality is

excellent on all bands. The bands between 40 and 10m show the

intermediate results that are to be expected, without any odd behavior

on any band. The drain voltage waveform deformations get larger as the

frequency rises. Instead it looks very clean on 160m, where the

leakage and

stray inductances in the feed circuit are small enough to cause almost

no effect.

Harmonic suppression is good enough to meet legal requirements only

when using a suitable lowpass filter. That's true even on 160m. It's

fine to operate on 12m using the 10m filter, even operating on 15m with

the 10m filter still meets requirements, barely, while operating on 17m

with the 10m filter doesn't meet them, with the second harmonic being

suppressed less than 40dB. So an all-band setup using

this amplifier would require switchable filters for 160, 80, 40, 20, 15

and 10m. If a push-pull driver would be used, probably the even-order

harmonics would be low enough to allow eliminating the 15m filter

and meet legal requirements on 17m using the 10m filter.

Reality check: The TS-450S

When

testing RF power amplifiers one can easily get depressed. In such cases

it's good to compare to what the competition achieves. Here is a

spectrogram of my Kenwood TS-450SAT's output on 10m. The 3rd

IMD

is down 29 to 30dB from each tone, which is almost as good as the Red

Pitaya with my homebrew amplifier when not using predistortion. But the

Kenwood is worse then my setup regarding the higher IMD products, and

is very much worse in phase noise! Of course, we are comparing

different technological generations here. The TS-450 only

has linear signal processing, with a balanced modulator, an

SSB

filter, several further stages of mixing, and a complex frequency

synthesizer that includes two DDS blocks and several PLLs. The Red

Pitaya setup instead does almost everything digitally,

even the

generation of the dual-tone test signal. That does allow better signal quality.

When

testing RF power amplifiers one can easily get depressed. In such cases

it's good to compare to what the competition achieves. Here is a

spectrogram of my Kenwood TS-450SAT's output on 10m. The 3rd

IMD

is down 29 to 30dB from each tone, which is almost as good as the Red

Pitaya with my homebrew amplifier when not using predistortion. But the

Kenwood is worse then my setup regarding the higher IMD products, and

is very much worse in phase noise! Of course, we are comparing

different technological generations here. The TS-450 only

has linear signal processing, with a balanced modulator, an

SSB

filter, several further stages of mixing, and a complex frequency

synthesizer that includes two DDS blocks and several PLLs. The Red

Pitaya setup instead does almost everything digitally,

even the

generation of the dual-tone test signal. That does allow better signal quality.

It would be interesting to compare the performance of my amplifier with

the Red Pitaya to that of a commercial radio of comparable technology,

such as the Icom IC-7300. But I don't have one...

The Kenwood consumes 1.4A in RX. Transmitting the dual tone signal it

consumes 10.3A, producing 90W PEP output. With a single tone

at

the same power it consumes 15.67A. That's 41.6% overall efficiency,

including all low-level processing. I don't know how much the low-level

processing really takes, but assuming it's the same as in RX, that

would leave 14.27A for its TX amplifier chain, allowing honest

comparison to my amplifier. It would put its amplifier's overall

efficiency at 45.7% on 10m, quite similar to what mine achieves.

The difference in efficiency is on the lower bands, where the Kenwood

has essentially the same efficiency as on 10m, while my amplifier gets

much better. That's due to my feed transformer that works

reasonably well on low bands but not on 10m. The Kenwood doesn't have a

feed transformer, so it works equally poorly on all bands.

In any case my little amplifier is good enough to use on all bands, and

excellent on the lower bands, which is where I actually use it. With the

Red Pitaya and PowerSDR's adaptive predistortion, it generates an

exceptionally clean signal. Considering that it uses a simple circuit and an inexpensive

output transistor, I think it's a good result.

If an amplifier like this is scaled to higher power, such as using a

BLF188XR to get 700-800W at a 50V supply, the larger feed transformer

required to handle the higher voltage will make the amplifier cross

over from clean low-frequency behavior to dirty high-frequency

operation at a lower frequency than my small amplifier does. With a

well optimized feed transformer, such a big 50V stage would probably

deliver best efficiency on 160 and 80m only, dropping slightly on 40m,

strongly on 20m, and working as badly on 10m as an amplifier that

doesn't have a feed transformer.

I will use this small amplifier not only on the air, but also to test

various ideas about achieving cleaner and more efficient operation

on the high bands.

Back to homo ludens electronicus.

Almost