Spot welder using a microwave oven transformer

Building spot welders out of old microwave oven transformers

has become kind of a sport. Lots of people are doing it, since there

are so many old MOTs out there, just asking to be put to good use!

One can't expect stellar power and performance from one of

these, given that for a good spot weld in thick material one needs a

peak power of tens of kilowatts, which a MOT can't deliver. But for

small jobs, such as welding tabs to battery cells, they work

great.

A

long time ago I joined this sport, and put together a simple MOT spot

welder, just for that task. I never put it in a box, so it's not a

finished project, but since it works well, I now decided it to put it

on my website anyway.

Any usable spot welder needs an adjustable

timer, that controls the

duration of the current pulse. The idea of spot welding is to compress

the two parts to be welded between two electrodes of much higher

electrical conductivity, then apply a brief, intense current pulse that

melts a small spot of metal where the two pieces meet, and then keep

the pressure while that metal again solidifies, cleanly welding the two

parts together. The timing needs to be just right. So any attempt to

work

without a timer will result in either burned metals, holes, or

something more

akin to arc welding than spot welding.

Larger spot welders also

control the amount of current, but a MOT spot welder is always a little

too weak anyway, so there is no point in further reducing the current.

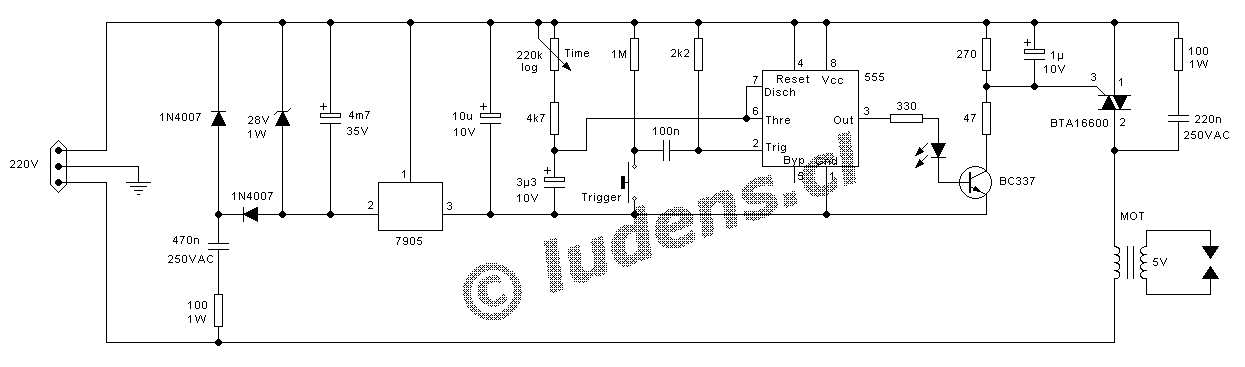

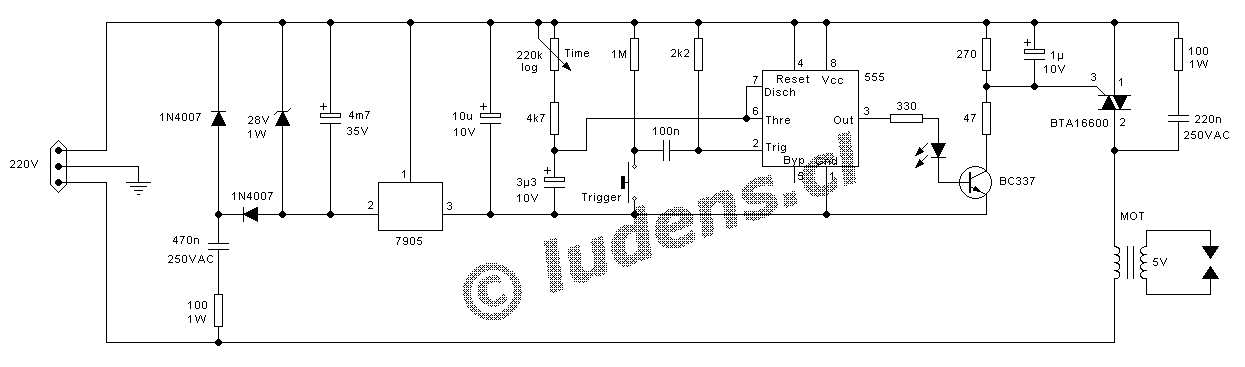

In

my design there is no current control, and the timing is implemented

simply in a 555 timer IC in monostable configuration. The timing

components are selected to give a pulse adjustable from roughly one

single cycle of the AC grid, to nearly one second. This pulse is used

to control a TRIAC, which is fitted with a snubber network to prevent

problems caused by the highly inductive load presented by the MOT.

The

timer circuit is powered directly from the grid by a cheap reactance

supply, saving an additional small power transformer. This supply can

provide only about 15mA, which is insufficient for triggering a TRIAC,

and for that reason a relatively large filter capacitor is used, which

provides enough reserve to deliver about 80mA of trigger current to the

TRIAC for the duration of a welding pulse.

TRIACs work fine when

the gate trigger voltage is the same polarity as the load, and they

also work fine when the gate trigger voltage is always negative.

Instead they are less good, and some don't even work at all, when

the gate trigger voltage is positive and the load is negative. So, my

circuit triggers the TRIAC with negative voltage, and for that purpose

the timer circuit is powered from -5V, provided by a negative

voltage regulator, the 7905. This circuit might look a little confusing

to people accustomed to always having a negative ground, and regulating

the positive line, but there is nothing wrong with it! It's just a

little upside down...

The 7905 can of course be any

brand, which determines the letters in front: LM7905, UA7905,

L7905, MC7905, and so on. The pinout stated is for a TO-220

package. Likewise, the 555 timer can be any brand and letters, like

NE555, LM555 and others. CMOS versions of the 555 should work too, as

long as it is one that has enough driving capability. Not all CMOS

versions do. If in doubt, better use a basic 555.

I used a

BTA16600 TRIAC, simply because I had some in my treasure chest, and it

works fine, but this isn't the optimal kind of TRIAC for this task.

It's a 4-quadrant TRIAC, and these are often a little sensitive to

self-triggering with inductive loads. So, if you have to buy the TRIAC

for this project anyway, it would be best to get a 3-quadrant TRIAC

instead, such as the T1635-8T. Although these are advertised as

"snubberless", do keep the snubber in this application!

Neither

the TRIAC nor the voltage regulator need a heatsink, since the

welding pulses are short, and typically with long pauses in between.

Instead of the BC337, any small NPN transistor that can comfortable handle at least 100mA should work fine.

The

470nF and 220nF capacitors need to be rated for direct AC line

connection. The kind that has a collection of safety agency logos

printed on them, commonly known as X capacitors.

And the

electrolytic capacitor marked "4m7" is 4.7 millifarad, which is

4700 microfarad! Don't get that wrong. I often wonder why

electronicans love talking about thousands of microfarads, while they

don't usually talk about millions of milliohms, or anything like

that...

The potentiometer should be a logarhythmic one,

if you can find it, to give a nice spread of time values. If you use a

linear one instead, the shortest pulse lengths might be hard to

set.

The trigger switch is best implemented as a foot switch,

so you can keep both hands free to hold the electrodes, and the parts

to be welded. Anyway one typically needs at least three hands, if not

four, when spot-welding without a proper jig, clamp or other

device! So don't plan on using your fifth hand for the trigger switch...

The

MOT is prepared for this use by cutting out the high voltage winding

and the filament winding, and keeping in place the primary winding and

the magnetic shunts. Then the freed window space is used to wind two

turns of the absolutely thickest, stranded copper wire you can get

through. The wire ends should not be too long, and end in massive

copper electrodes, that have dull conical tips of about 1 to 2mm

diameter, depending on what you want to weld, and the power of your

MOT. Those copper electrodes should be at least 6mm or so in diameter,

preferably something like 10 to 12mm. We are talking about a current

like 500A, at just a few volt, so the total circuit impedance must

not be higher than a few milliohm, and we want as much as possible of

that to be the resistance of the material we want to weld, NOT the

electrodes nor the wiring!

The whole spot welder should be built

into a metal box, grounded to the earth contact of the power

plug. The entire circuit is at line potential, so it should be

protected from accidental touch. Don't be as lazy as I am! I never

put mine into a box, as I should, since I use it only very

rarely. I just built the timer on a perfboard, and the power part in

self-supported 3D style, and I hold both welding

electrodes in my hands. So please excuse me for not wanting to show you

photos of my contraption, but at least you can see the schematic

diagram, which looks a lot nicer than my practical implementation of

it! You can even click it to get a high resolution version, which

is good for printing.

Back to homo ludens

electronicus.