Power inductor tester

When building or repairing switching power supplies of all sorts, and

also in many other situations, it's essential to be able to test and

measure inductors and transformers. While there are some inductance

meters available cheaply enough, they tell only part of what one needs

to know, because they usually are unable to test an inductor for

saturation current, let alone determine its linearity.

For that reason I built a simple gadget that in combination with a lab

power supply and an oscilloscope will allow measuring

inductance, see

the magnetization curve of an inductor, find out saturation current,

how sharp the

saturation is, and see whether the inductor actually saturates, or is

current-limited by resistance.

Magnetic components such as inductors and transformers are the least

understood by most people doing electronics. So this little gadget also

has a considerable educational value!

I built the first inductor tester of this type more than 20 years ago.

That version never got a housing! It lived naked, free and healthy, all

components in

clear air. Then, about ten years ago, I built a more modesty-endowed

one into a little plastic

box. That's the version I'm finally publishing here!

This circuit can test inductors over the whole range of inductances

usually seen in switching power supplies, inverters, chargers, motor

controllers and the like, and it is capable of testing the saturation

current up to about 100A.

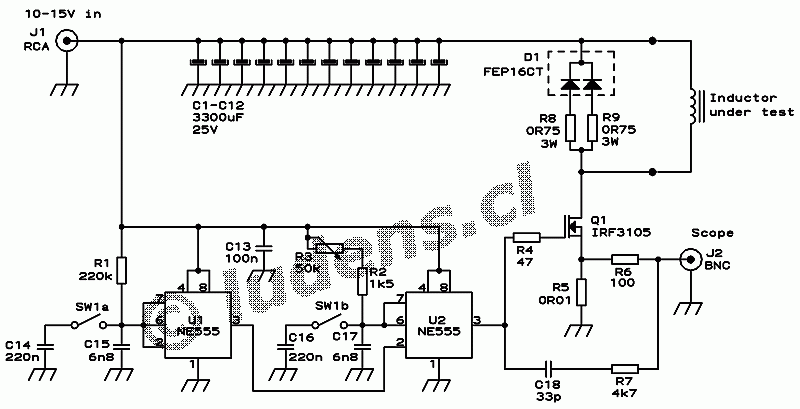

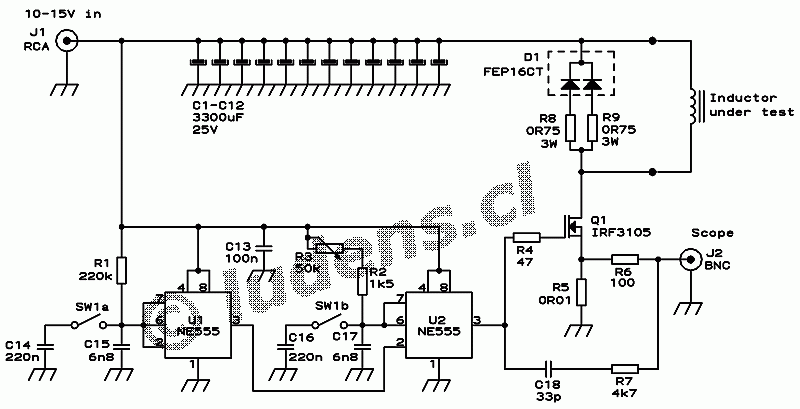

As you can see, the circuit is very simple. There is a big bank of

capacitors, a timer circuit using two 555 ICs that generates a train of

variable length pulses, driving a MOSFET that applies these pulses to

the inductor under test. The inductor current is sensed by a low value

resistor, the resulting voltage being applied to an

oscilloscope,

where the measurements are made.

The first of the 555 chips generates the repetition rate of the pulses,

while the second 555 generates the actual pulse length applied to the

inductor. There is a range switch, which selects the timing capacitors

for both timers, and a potentiometer that fine-adjusts pulse length. In

the slow range, the repetition rate is roughly 20Hz, which is about the

slowest that allows getting a stable, easily readable trace on a

typical scope. The pulse length is adjustable from

roughly 300µs

to 10ms in this range. In the fast range the pulse length goes from

10µs to those

300µs, and the repetition rate is roughly 600Hz, which

gives a good trace intensity at the sweep rates used for those pulse

lengths. So, this circuit basically covers the pulse length range of

10µs to 10ms, with appropriate repetition rates.

The output of the second 555 directly drives a high current MOSFET,

which connects the capacitor bank to the inductor under test. The

capacitors are conveniently charged to slightly over 10V from a current

limited lab supply, so that the voltage applied to the inductor is as

close as possible to 10V. This simplifies further calculations. But any

supply voltage from 10 to 15V can be used.

The current sense resistor is 10mΩ, so that the output to the scope has

a scale of 10 millivolt per ampere. A very narrow sample of

the

drive pulse is also coupled to the scope output through C18 and R7, to

facilitate scope triggering at the start of each pulse.

Finally, there is a diode/resistor circuit to safely discharge the

inductor after each pulse finishes, instead of frying the MOSFET!

Click on the schematic if you want a larger, better resolution version.

And fix the MOSFET number, it's really an IRF3205, not 3105! It seems I

misplaced the original schematic file, so I can't fix it

myself...

I used a 3105 at first, but later changed it to a 3205, which has much

lower resistance.

I built the circuit on two pieces of perfboard. One holds the power

circuit, prominently including the collection of electrolytic

capacitors. I didn't buy these, but instead raided my

collection of

junked electronic boards, and robbed every 3300µF capacitor I

found! When you build your version, of course feel free to use any

large capacitors you happen to have. The goal is to get roughly

40,000µF or more, along with a very low ESR. A voltage rating of 16V is

actually enough, and any more won't hurt.

The MOSFET and power diode don't neet heatsinks, thanks to the low duty

cycle they work at.

The control circuit was assembled on a separate board, both for

practical reasons, and to prevent magnetic interference from the high

pulse current into the timer's high impedance areas. The range switch

was mounted on this board, so that the whole board can be conveniently

supported just by that switch.

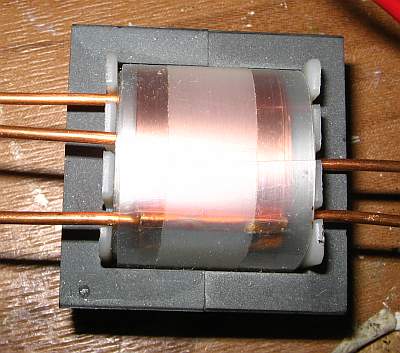

This peek allows you to see the thick wires used to interconnect the

capacitors, MOSFET, diode and power resistors. We want low ESR, right?

If you look carefully, you will notice that most wires are copper, but

there is one shiny silvery wire. That's the 10mΩ resistor! It's a plain

and simple piece of galvanized steel fencing wire! I think the gauge

was AWG #16. Its temperature coefficient might not be the best, but

it's cheap, available, easy to solder, and works well enough! I often

use galvanized steel wire to make such low value power resistors.

And here you can see how the boards and other stuff fit in the little

plastic project box - just barely.

I used a BNC connector for the scope output, and an RCA connector for

the power supply input. Instead the connections to the inductor under

test have no connectors at all. Instead I used thick, short stranded

wires, which I tack-solder to the inductors. That's a lot better than

using any clip connectors, when we want to push 100A pulses through

them, and don't want much resistance!

So much for the construction of this gadget. Now let's go on to using

it!

The inductor tester must be powered by a current-limited power

supply, because otherwise it would be easy to far exceed the power

dissipation capabilities of the discharge resistors, when setting the

controls to a pulse length too long for a given inductor. The power

supply should ideally be adjustable to slightly more than 10V, say,

about 10.2V for low current inductors, and up to 12V for the

biggest ones. If such a supply isn't available, a fixed 12V will do,

but then you will probably need a calculator instead of just your head,

when doing the math.

The current capability of the supply should be about 1A. That will

suffice for almost all tests you will want to do. But if you run out of

juice when testing a very large inductor, you might want to increase

the current limit to 2A or even 3A, but then do only very brief tests,

or you will melt down the tester! On the other extreme of things, when

you test tiny coils and transformers, this gadget can easily deliver

enough current to vaporize thin wires and completely melt down

small coils, so you really should use a lab supply that has a

current limit adjustable down to a low value. I like to use a 100mA

limit when testing small components, and even that can be too much for

the smallest ones!

The idea, in any case, is that if you set a pulse time that's too long,

the power supply should go into current limit well before your inductor

under test gets damaged, or the tester itself lets out its magic smoke!

The scope needs to have a calibrated scale, DC response, and be able to

trigger on the positive edge. Essentially every scope, except absolute

antiques from the time of WW2 and before, meets these requirements.

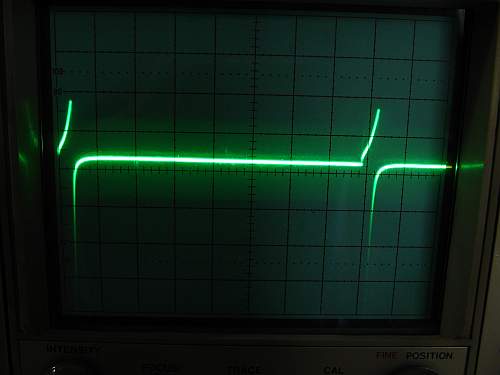

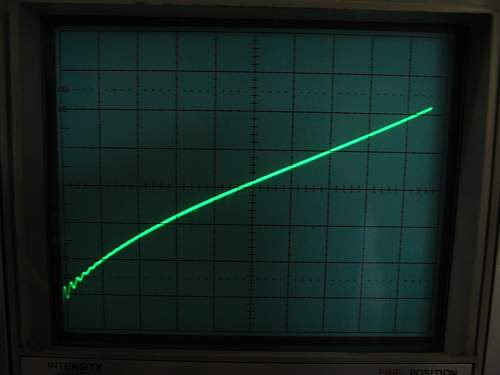

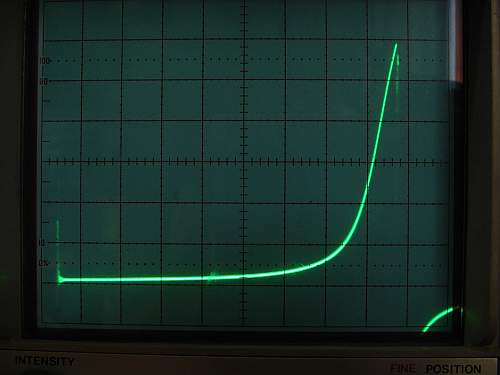

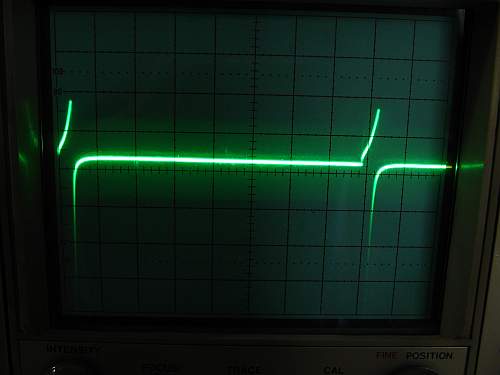

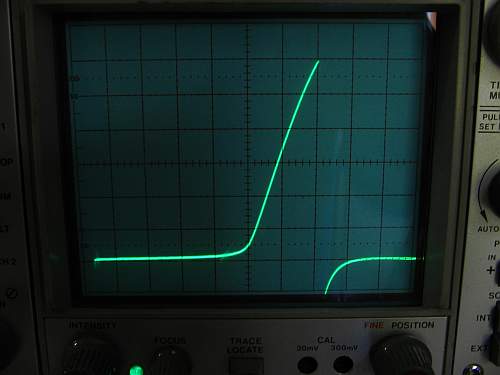

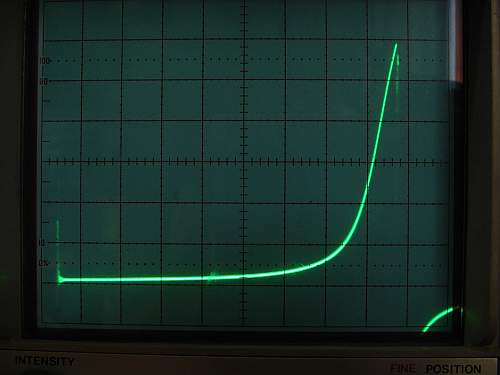

This is the complete waveform displayed on the scope. It begins with a

positive ramp, as the current in the coil increases while the circuit

applies 10V to it. Typically this ramp will not be linear - it can have

one, two or even more bends in it, caused by saturation and other

nonlinear effects of the core, by the winding resistance, and

even

by the tester.

Then the ramp ends, which results in a negative pulse coming

both from the drive circuit and MOSFET capacitances. Note that this

isn't the inductive discharge of the coil! That one is routed away from

the scope. Although some of the inductor discharge current might be

magnetically coupling to the scope output.

And then comes a rest time, after which the cycle repeats. If you look

very carefully, you can see the positive trigger pulse at the start of

the second ramp. The one at the first ramp is hidden by the first grid

line!

You should start testing an inductor by connecting the inductor

(soldering it), setting the tester to the shortest pulse length, then

switching on the power, adjusting the scope to see at least the full

first ramp and some area around, and then slowly increase the pulse

length until you see the ramp bending upwards. This is the saturation

point of the inductor, and it usually makes little sense to test at any

higher current. Don't crank up the pulse length much further, or you

will get really large current pulses, and possibly some smoke.

What you have to do now is adjust the scope to see the interesting part

of the curve in good detail. That's the entire ramp until the

saturation point, in most cases.

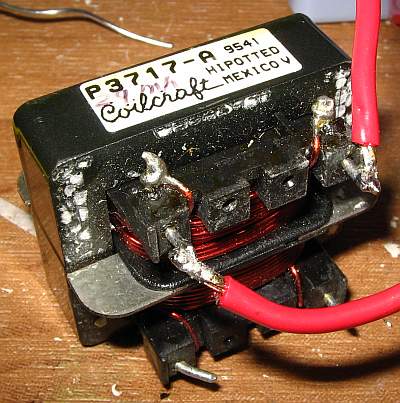

Let's start with this animal. It's the filter choke of a multivoltage

half bridge forward converter, a.k.a. PC power supply. It's wound on a

toroidal core made from very dense, fine grained, powdered iron. These

cores have a permeability of around 70 to 100, which is the highest

available from powdered iron.

For the test, I connected only one of its windings. I think it's the

12V winding. The other windings were left open.

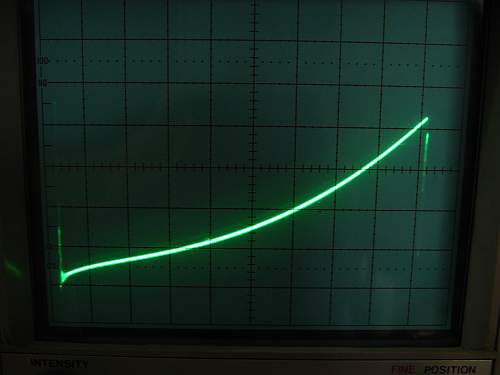

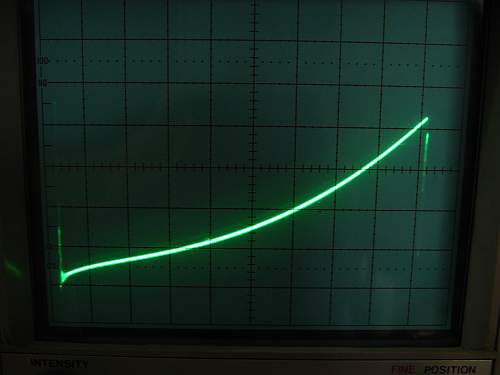

This is the ramp I got. The scope is set for 100mV and 10µs per

division. What we can see is that after some ringing where the ramp

starts, given by stray capacitance, the ramp starts at a certain angle,

then after about 5µs gets slightly less steep (meaning the inductance

increased at that current level!), and then after about

30µs the trace gets steeper again (inductance is reducing at

that

current level). This reduction of inductance continues, and is known as

the saturation knee. Eventually the trace gets straight again, much

steeper than at the beginning. It's here where the core is completely

saturated, and we have basically the same inductance left as if the

winding had been made on thin air instead of an iron core.

The saturation of this core is very soft, indicated by the soft knee,

having a large radius, compared to the size of the whole ramp.

Zero voltage is at the line one division up from the bottom. If we

take as saturation limit the middle of the knee, which is

roughly 50µs after the beginning of the ramp, this is a

voltage of

150mV. Considering that the inductor tester has a 10mΩ sensing

resistor, this means a coil current of 15A. So we can say that this

inductor saturates very roughly at 15 amperes flowing in its 12V

winding. By counting the number of turns and multiplying that by this

current, we can arrive at a certain amount of ampereturns that

will saturate this particular core, but we have to keep in mind that

with the saturation of this core being so soft, it's hard to

say

at which level we will consider it to be saturated!

To measure the inductance of this winding, the scope settings above are

not good enough. The inductance we usually want to measure is

the amount before saturation, and that part of the trace is too small

to allow precisely reading the screen.

So, first we reduce the pulse length, to finish the pulse

before

the core saturates. The scope settings in this shot are still the same,

just the pulse length was reduced.

And then we readjust the scope to make good use of the screen. In this

case the settings are 10mV and 2µs per division.

The inductance that's most meaningful in power electronics is the one

at medium currents, well before saturation, but not at very low

current. Anyway this simple inductor tester has some parasitic effects

at the very start of the pulse, given by the gate charge pulse of the

MOSFET, so it's better to avoid that area. So I will take the last 5

horizontal divisions of this trace, where it is a nice straight ramp.

This is 10µs, and 2.2 vertical divisions, which is 22mV, representing

2.2A. So we know that with 10V applied, this inductor lets the current

grow by 2.2A in 10µs. And now we can apply the definition of the Henry:

H = V × s ÷ A

Inserting our values,

10V × 0.00001s ÷ 2.2A = 0.000045H

So the inductance is 45µH.

Since it's easy enough to count the number of turns of this winding, we

can now calculate both the AL value and the saturation ampereturns for

this core, and those are the main bits of data needed to design any

coil using it! Just the core loss is a separate entity that this tester

does not measure easily. Still, you can take any unknown core, wind a

test coil on it, and use this tester to determine the core's main

characteristics. That's a very useful thing to do!

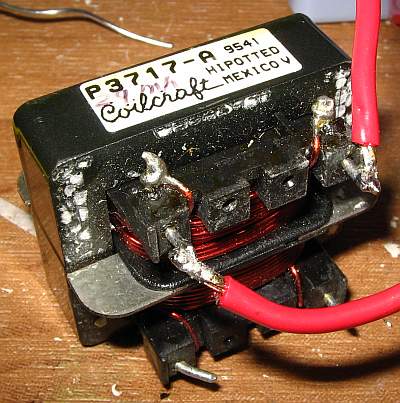

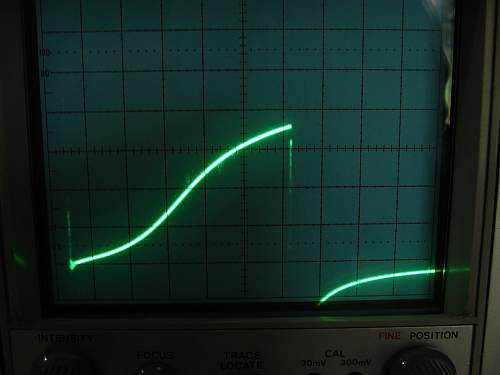

Let's try another guinea pig. This slightly injured but still perfectly

functional thing is a common mode choke, intended to be used in noise

filters at the input of switching power supplies. They are usually

wound on high permeability ferrite, which has a strong resistive

(lossy) component in the RF range, producing good absorption of

unwanted RF signals.

Like in the case above, I connected just one winding.

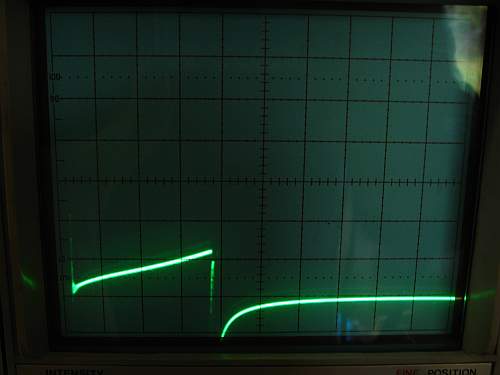

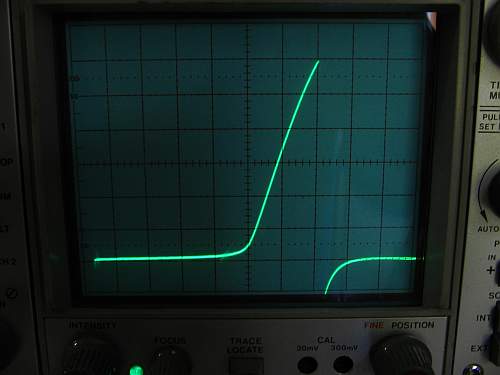

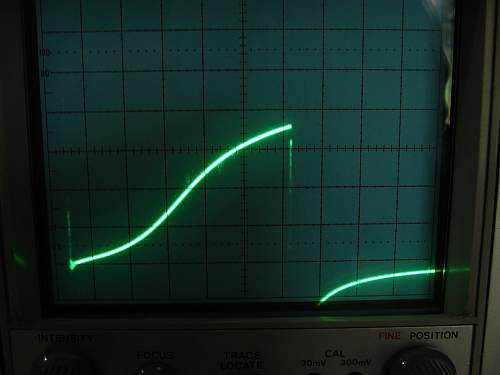

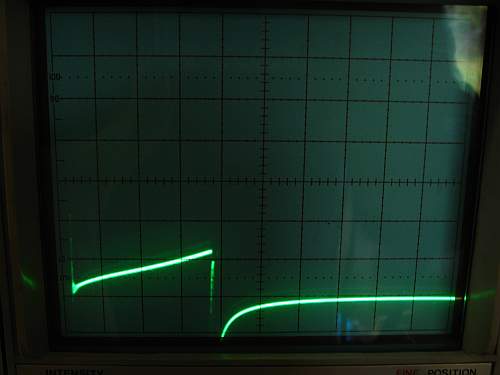

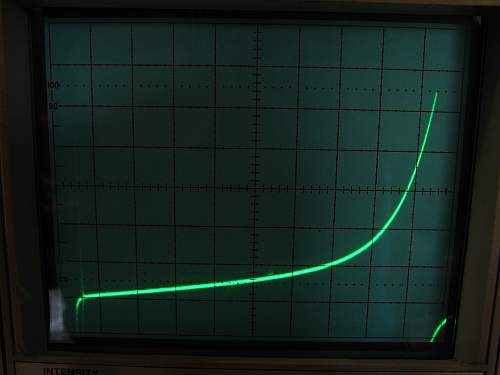

This shot was made at 20mV and 100µs per division. The very sharp, well

defined saturation knee is immediately obvious. Before the knee, the

ramp has a very low slope, indicating a high inductance. After the

knee, the inductance is very much lower.

Just for fun, let's calculate how much inductance there is, when the

core is saturated:

In 5 vertical divisions we get 1.8 horizontal ones. That's 100mV,

meaning 10A,

in 180µs. The applied voltage is of course 10V, defined by the lab

power supply. So:

10V × 0.00018s ÷ 10A = 0.00018H, or 180µH.

Remember that this is the inductance when the core is saturated!

Now I have reduced the pulse length to include the saturation knee but

stop after it, and I have reset the scope to 1mV and

50µs

per division. We can see that significant saturation starts at

1

division up from the zero line (0.1A), the knee is centered roughly on

1.6 divisions (0.16A), and the core is totally saturated at roughly

0.4A in this coil.

Over the usable part of the ramp, before saturation, we get about 0.6

vertical divisions in 5 horizontal ones. That means 0.06A in 250µs,

which results in roughly 42mH. Note this is millihenry,

while all inductances mentioned above were much smaller, and indicated

in microhenry!

So, we can say that a single winding of this common mode choke has an

inductance of 42mH, has hard saturation at roughly 160mA, and when

saturated it has 180µH left - which means that the inductance

drops

by a factor of 233 due to saturation!

This behavior is typical of inductors wound on high permeability

ferrite cores, without air gaps. In fact the sharp saturation of this

choke is an indication that the residual airgap, which results from

imperfectly polished mating surfaces of the core halves, is very small,

indicating good quality of the core finish.

Just to prevent risking any wrong conclusions on the side of my

readers: The normal way a common mode choke is used consists of

connecting its two windings in series with the two poles of the power

line. So, all the big current flows through the two windings in

opposite senses, canceling the magnetic flux. For this reason this

common mode choke can take several amperes in its normal operation

mode, without getting even close to saturation. The actual working

current is limited by heating of the wire, and not by the

core!

Also the choke will oppose almost no inductance to such normal mode

(differential mode) currents. But it will oppose its full non-saturated

inductance to low frequency common mode signals, and at RF it will be

lossy, absorbing RF noise.

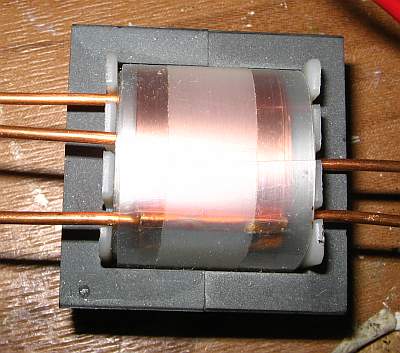

Here we have our next guinea pig: A homemade tape-wound transformer

intended for a 12V to 220V inverter. It has a 2×12V primary and a 45V

secondary. Several push pull converter blocks, each using one

of these

transformers, are connected with their secondaries all in series.

For

this test, I used the secondary winding.

The trace resembles that of the common mode choke. After all, both use

high permeability, ungapped ferrite cores! But one difference is

obvious: The knee is softer. This is due mainly to this low cost core

having less well polished seating surfaces, so that there is a

significant, irregular air gap. As a result, granules of ferrite

actually touching at the joint of the core halves will take lots of

flux, and saturate first, while those granules separated by some air

will only then start taking more flux, and saturate a little later. The

whole core will saturate well after that. This spreads the saturation

phenomenom over a wider current range, extending and softening

the

knee.

Another difference is less obvious: The ratio of the

inductances

in saturated and non-saturated conditions is a little less extreme than

for the common mode choke. This is because the ferrite used for this

transformer has a slightly lower permeability.

And of course the absolute values of inductance and saturation current

are different, due to totally different turn numbers and core

dimensions.

The inductance measured in a transformer like this defines the

magnetizing current it will take, when a certain voltage and frequency

are applied. This magnetizing current needs to be kept below the

saturation level, and at any frequency above roughly 10kHz it needs to

be kept even lower, in order to avoid excessive core loss and heating.

The actual current carried by each winding can be very much larger,

because the primary and secondary currents cancel out, except for that

magnetizing current.

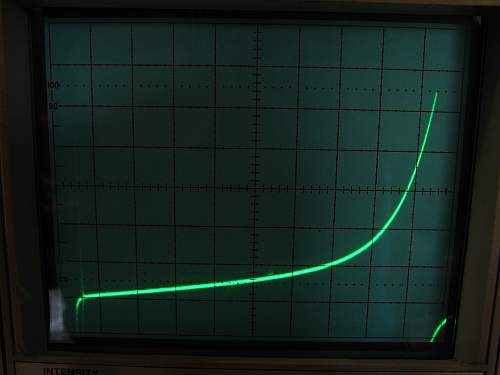

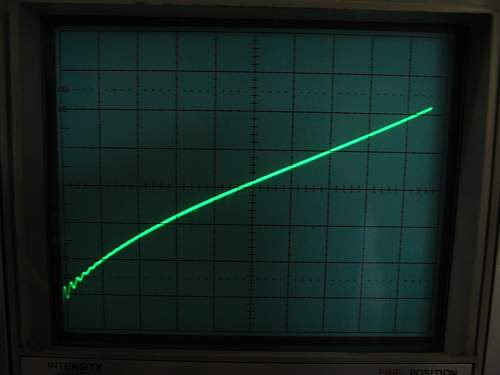

Let's take this last test coil, to illustrate a few more points. This

is an FT-240-61 toroid, made from low permeability ferite, wound with a

quick and dirty trifiliar winding that I used to generate a balanced

signal for an equally quick and dirty test, some time ago. Now I pulled

it out of my

junk box, and connected the three wires in series. This stranded wire

is quite thin, so it has a significant resistance at high currents.

This is the curve it gives. It's nice, because it allows us to see a

pretty linear ramp at the beginning, then a moderately soft saturation

knee, then a steeper ramp in the saturation area, and then a roll-off

toward a horizontal line. This last bend is caused by the wire

resistance. The scope was set for 200mV per division, meaning 20A per

division, so the trace ends at a current of roughly 72A, at which the

thin stranded wire is seriously limiting the current due to its

resistance. It looks like the curve would level off at roughly

80A. Knowing that there are 10V applied, this means that the total

resistance of the winding is 0.125Ω, which seems quite reasonable for

the length and size of wire used. Which shows that my little gadget can

even measure coil resistance, in a more fancy way than using a

multimeter!

Note that the saturated and unsaturated inductances are far less

different than in the other ferrite cores above. That's because of the

low

permeability of this ferrite, barely a bit higher than that of the

powdered iron core at the beginning!

There is no need to worry that this crooked curve could distort the RF

signals, when using this core for a high power balun, as is often done.

Due to the high core losses at RF, all signals are kept to very low

flux levels,

so low that they would be hidden in the blurry spot at the very

beginning of this trace! At that low flux level, the balun is

completely linear, for all practical purposes.

Audio transformers instead, which often use quite high flux densities,

do

suffer from distortion introduced by core nonlinearity. The

core

magnetizing curve directly affects the magnetizing current, and through

several effects this impacts the signals in an audio transformer.

That's the main reason why HiFi sound reproduction became so much

better when tubes, with their almost inevitable transformers, were put

in the museum, and replaced by transformerless solid state circuits.

Tube audio fans will of course tell you the opposite story, in the line

that tube equipment sounds better, because

of the transformer and triode distortions! What sounds more enjoyable,

the clean audio or the distorted one, is a matter of taste...

But that transformerless equipment has less distortion, is an

easily measurable and

audible fact.

Well, enough playing for now. If you want to keep playing and testing

inductors, learning how they work, build your inductor tester and use

it!

Back to homo ludens

electronicus.