160V 3A DC motor power supply

Several

years ago I purchased a small lathe. It's one of my nicest toys. This lathe came with a plain and simple

single-phase 0.5 HP induction motor, Chinese-made, which took a

tremendous current pulse to start up, and also caused quite a lot of

vibration. It worked for a few years, then one day it smoked off.

Instead of repairing it, I replaced it by a small permanent magnet DC

servomotor, made by Minertia, which I had gotten as a gift. It had been

used in some large line printer. This motor worked fine, free of

vibration, but it wasn't powerful enough for my larger jobs - it was

rated at just 60 watts or so!

Several

years ago I purchased a small lathe. It's one of my nicest toys. This lathe came with a plain and simple

single-phase 0.5 HP induction motor, Chinese-made, which took a

tremendous current pulse to start up, and also caused quite a lot of

vibration. It worked for a few years, then one day it smoked off.

Instead of repairing it, I replaced it by a small permanent magnet DC

servomotor, made by Minertia, which I had gotten as a gift. It had been

used in some large line printer. This motor worked fine, free of

vibration, but it wasn't powerful enough for my larger jobs - it was

rated at just 60 watts or so!

Two years later I got the chance to buy a used German-made DC motor,

rated at 170V and 3,1A. This was much better. I installed it in my

lathe, and provisionally powered it from a transformer/rectifier/filter

type power supply, but the transformer was so large that I had to

mount that power supply externally to the lathe. So I finally designed

and built a switching power supply to feed this motor, which is small

enough to fit inside the base of this little lathe. This power supply

was designed to be switched on and off together with the motor, and to

provide current limiting, which is important to avoid demagnetizing the

magnets in the motor during startup or overload conditions.

Most of the components used for this power supply were taken from old,

junked electronic equipment. A CRT monitor was the most important donor.

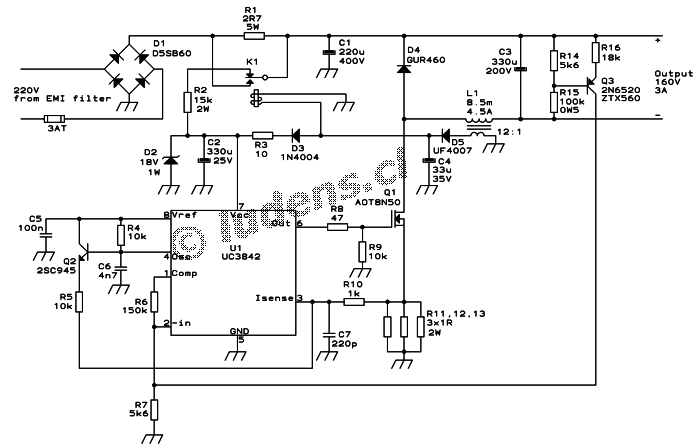

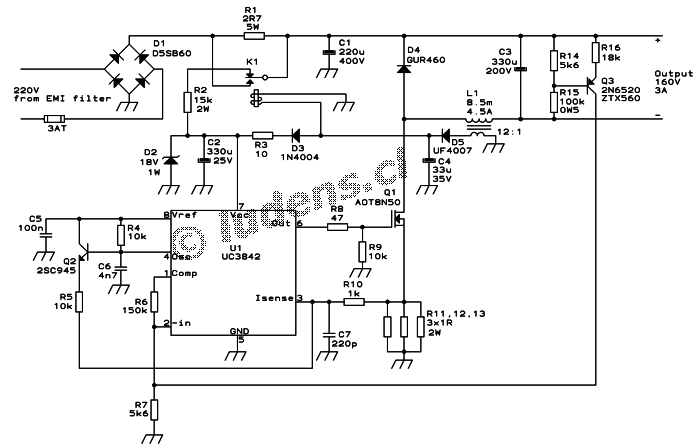

The

circuit of this power supply is rather unorthodox. As this power supply

is for a 500 watt level, most designers would make a

fully fledged half bridge or even full bridge circuit. But my lathe

motor doesn't need its DC to be insulated from the grid! So I made

a simple buck converter circuit, utilizing just one MOSFET,

controlled by the ubiquitous UC3842. To make matters more fun, I placed

the MOSFET on the negative side of the circuit, allowing me to use a

cheap N-channel MOSFET, directly driven by the IC. Some people would

have trouble visualizing this as a simple buck regulator, without first

reading this explanation! But it is.

The

circuit of this power supply is rather unorthodox. As this power supply

is for a 500 watt level, most designers would make a

fully fledged half bridge or even full bridge circuit. But my lathe

motor doesn't need its DC to be insulated from the grid! So I made

a simple buck converter circuit, utilizing just one MOSFET,

controlled by the ubiquitous UC3842. To make matters more fun, I placed

the MOSFET on the negative side of the circuit, allowing me to use a

cheap N-channel MOSFET, directly driven by the IC. Some people would

have trouble visualizing this as a simple buck regulator, without first

reading this explanation! But it is.

One matter that requires attention with such a circuit is that the

output is referenced to the positive rail, so it's galvanically far

away from the control IC, making voltage feedback harder to implement.

I have seen people who solve this problem by using

optocouplers, and so

these poor guys have to deal with all the instabilities of those

devices! Instead I used a simple current transmitter employing a small,

inexpensive high voltage PNP transistor and making use of its very high output resistance. It will inject a current into

the UC3842's feedback circuit, that is cleanly proportional to the

output voltage. This has proven a very effective solution, despite its

extreme simplicity.

This buck converter needs to operate at duty cycles that can far exceed

50%. For that reason I used slope compensation, implemented around Q2.

Without this, the loop would not be stable.

An important difference between this power supply and most others, is

that this one needs to start quickly, under full load, and needs to be

able to be restarted very soon after being shut down. This capability

was highly desirable in order to seemlessly incorporate this power

supply into my lathe, which has an AC-solenoid-latched run switch.

After the rectifier I used a relatively small input filter capacitor,

since a high ripple on it won't cause any trouble in this circuit, and

the small capacitor improves the input power factor. Also the small

filter capacitor helps to make the power supply run out of charge

quickly enough after being shut off, to keep it from driving the motor

for a noticeable time after being switched off. To limit the inrush

current, there is a 2.7 ohm resistor, which gets shorted out as soon as

the power supply has come up to normal operating voltage.

The supply for the UC3842 needs to rise quite fast, but also

needs to have a large reserve capacitance, to be able to power the IC

from the moment its undervoltage lockout releases, to the time it has

come up to normal voltage, spinning up the motor during this process.

So C2 is 330uF, a much larger value than what's usually

required, and it is charged through a 15k resistor from the rectified

mains to bring it up quickly, but to avoid excessive heating this resistor also gets de-activated

by the same relay that shorts out R1, as soon as the power supply

runs. As is usual with the UC3842, during normal operation the IC is

powered from an auxiliary winding on the output inductor (or

transformer, if there was one).

The output inductor has a value of 8.5 millihenries, and must not

saturate at currents up to at least 4.5A. I wound this inductor on a

plastic bobbin made on my lathe, using the ferrite core of an old CRT

monitor's flyback transformer. The core needs to be airgapped. The wire needs to have an

adequate size for 3A continuous duty, and the auxiliary winding that

powers the control IC has one twelfth the number of turns of the main

winding, and can be made from rather small wire.

If you click the schematic, you will get a large version of it, which

also includes the details of this inductor. If you don't find a core

exactly like mine, you can of course use find a ready made inductor, or

custom wind your own, using the info above, and the basic calculations

on my Transformers and Coilspage.

The full size circuit also gives basic data on the relay, and a

warning note that I will repeat here: The ground symbols on this

schematic refer to a floating common, and they must not be connected to

physical earth ground!

Note that in the schematic I mention an EMI filter. My lathe already

has one built in, intended to absorb the spark interference of the

original induction motor's starting circuit, so I didn't include any

additional filter in my power supply. But if you intend to use a supply

like this in some other application, you must include an EMI filter at

the input, or there will be serious interference emitted!

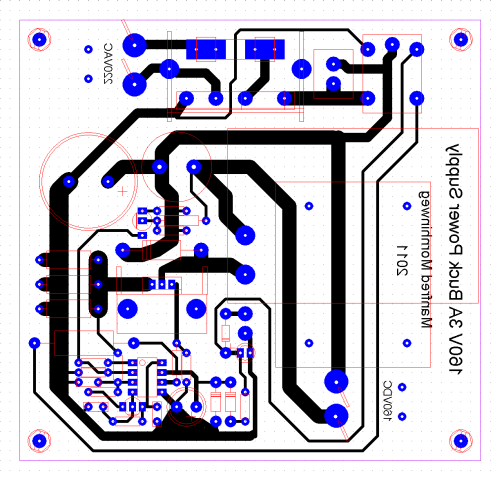

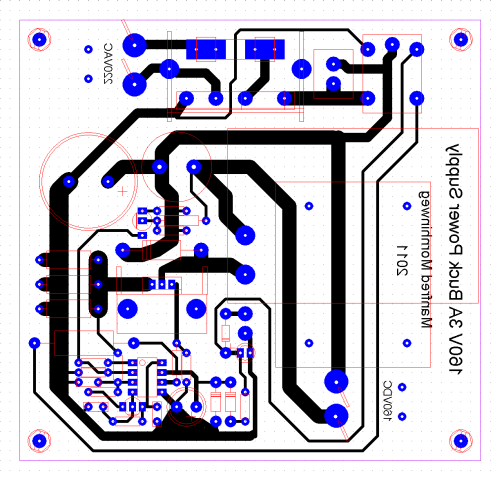

To make a compact and robust power

supply, I indulged in the luxury of building it on a printed circuit

board. All of the parts are on the board, which is single-sided and has

all of the connections on them. It is doubtful to what extent other

builders will be able to use this board layout, because it is heavily

dependent on the sizes and shapes of the exact components I used.

Anyway I'm providing the design here, seen from the component side. If

you click on it, you will get a larger version. You can see roughly

what part goes where, although the parts are not identified, only

outlined. It should be easy enough to populate the board following the

schematic.

To make a compact and robust power

supply, I indulged in the luxury of building it on a printed circuit

board. All of the parts are on the board, which is single-sided and has

all of the connections on them. It is doubtful to what extent other

builders will be able to use this board layout, because it is heavily

dependent on the sizes and shapes of the exact components I used.

Anyway I'm providing the design here, seen from the component side. If

you click on it, you will get a larger version. You can see roughly

what part goes where, although the parts are not identified, only

outlined. It should be easy enough to populate the board following the

schematic.

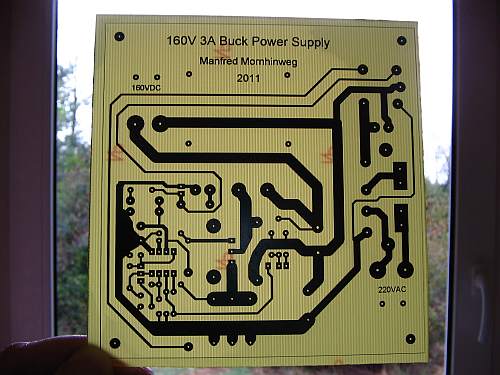

Here is the copper pattern for

this board. I saved it in x5 size, so if you downsize it by a

scale of 5, your printer should put it out at the precise scale, as

long as all programs work as they should, and no program does stupid

things on its own... But if they do, you will have to scale it

manually. It helps to know that the board size is 119.4 x 114.3mm.

Note that the board has several unconnected pads. These are intended

just as drill guides, to make holes through which to anchor the

inductor, and tie down the input and output wires.

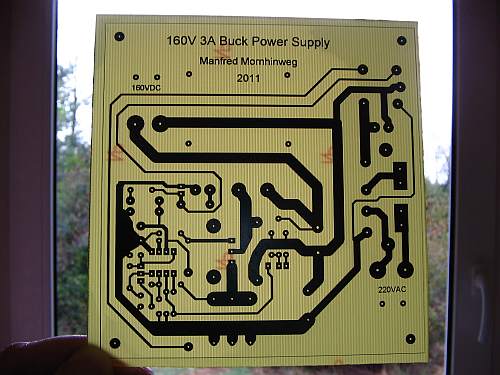

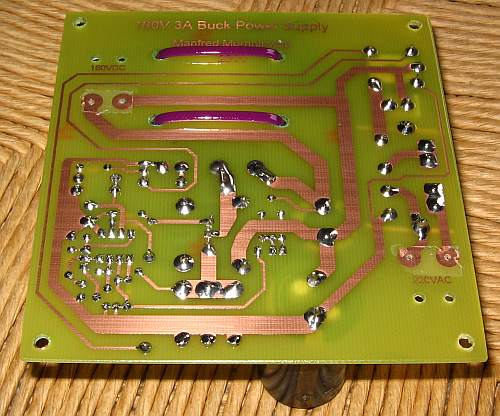

Here

is the board, just out of the ferric chloride bath. It has to be cut

down to its final size, drilled, the photoresist stripped off, and

protected by some solderable varnish.

Here

is the board, just out of the ferric chloride bath. It has to be cut

down to its final size, drilled, the photoresist stripped off, and

protected by some solderable varnish.

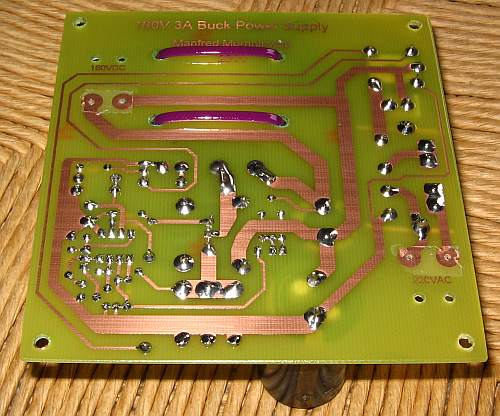

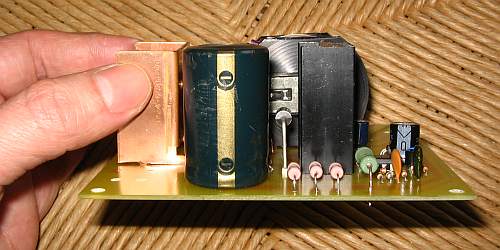

And

here the board has been assembled. After assembly I applied a thick

coat of acrylic varnish, to prevent creepage between nearby traces and

pads. Only the input and ouput pads, which had not yet been

soldered, were protected with little pieces of masking tape before

spraying on the varnish.

And

here the board has been assembled. After assembly I applied a thick

coat of acrylic varnish, to prevent creepage between nearby traces and

pads. Only the input and ouput pads, which had not yet been

soldered, were protected with little pieces of masking tape before

spraying on the varnish.

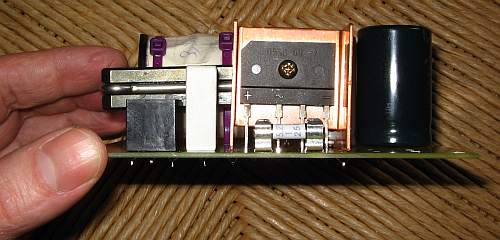

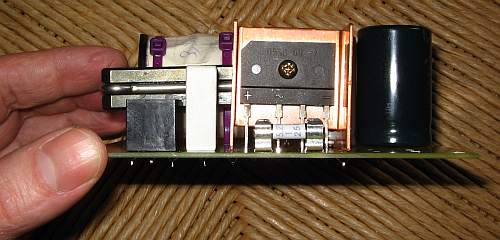

Seen

from the side, the compact built height of this power supply is

apparent. The room inside the base of my lathe is precisely 50mm high,

and the largest free space is 120x115mm. This dictated both the size of

the board, and the height of the tallest components. The full height of

the power supply, from the soldered pins to the tops of the tallest

parts, is 46mm.

Seen

from the side, the compact built height of this power supply is

apparent. The room inside the base of my lathe is precisely 50mm high,

and the largest free space is 120x115mm. This dictated both the size of

the board, and the height of the tallest components. The full height of

the power supply, from the soldered pins to the tops of the tallest

parts, is 46mm.

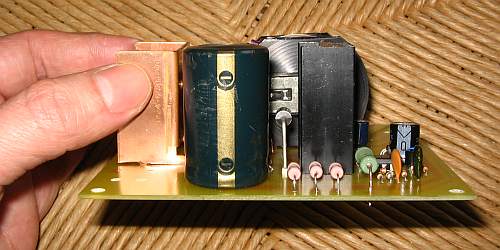

And

here is another view. You can see how some power components are

installed with long legs, to raise them above the board and allow them

to get good air flow.

And

here is another view. You can see how some power components are

installed with long legs, to raise them above the board and allow them

to get good air flow.

This little power supply packs a lot of power into a small size. After

all, it works at the 500 watt level! When machining larger parts, I

often work hard at the limit of the lathe, because that's fastest. The

heatsink cooling the MOSFET gets pretty hot under such conditions, but

since the MOSFET is used well below its limits, the operating

temperature is still completely safe. The other parts heat up much

less. The inductor stays cool, because it's significantly oversized. I

didn't have a suitable smaller ferrite core on hand...

With the DC motor and this power supply, my lathe

now works far better than when new. This motor has better

torque than the original one, and doesn't vibrate. There isn't such

a huge inrush current when starting, as there was with the

induction motor and its capacitor starting system. And in the

two years since I built this power supply, it has worked perfectly.

Back to homo ludens electronicus.

Several

years ago I purchased a small lathe. It's one of my nicest toys. This lathe came with a plain and simple

single-phase 0.5 HP induction motor, Chinese-made, which took a

tremendous current pulse to start up, and also caused quite a lot of

vibration. It worked for a few years, then one day it smoked off.

Instead of repairing it, I replaced it by a small permanent magnet DC

servomotor, made by Minertia, which I had gotten as a gift. It had been

used in some large line printer. This motor worked fine, free of

vibration, but it wasn't powerful enough for my larger jobs - it was

rated at just 60 watts or so!

Several

years ago I purchased a small lathe. It's one of my nicest toys. This lathe came with a plain and simple

single-phase 0.5 HP induction motor, Chinese-made, which took a

tremendous current pulse to start up, and also caused quite a lot of

vibration. It worked for a few years, then one day it smoked off.

Instead of repairing it, I replaced it by a small permanent magnet DC

servomotor, made by Minertia, which I had gotten as a gift. It had been

used in some large line printer. This motor worked fine, free of

vibration, but it wasn't powerful enough for my larger jobs - it was

rated at just 60 watts or so! The

circuit of this power supply is rather unorthodox. As this power supply

is for a 500 watt level, most designers would make a

fully fledged half bridge or even full bridge circuit. But my lathe

motor doesn't need its DC to be insulated from the grid! So I made

a simple buck converter circuit, utilizing just one MOSFET,

controlled by the ubiquitous UC3842. To make matters more fun, I placed

the MOSFET on the negative side of the circuit, allowing me to use a

cheap N-channel MOSFET, directly driven by the IC. Some people would

have trouble visualizing this as a simple buck regulator, without first

reading this explanation! But it is.

The

circuit of this power supply is rather unorthodox. As this power supply

is for a 500 watt level, most designers would make a

fully fledged half bridge or even full bridge circuit. But my lathe

motor doesn't need its DC to be insulated from the grid! So I made

a simple buck converter circuit, utilizing just one MOSFET,

controlled by the ubiquitous UC3842. To make matters more fun, I placed

the MOSFET on the negative side of the circuit, allowing me to use a

cheap N-channel MOSFET, directly driven by the IC. Some people would

have trouble visualizing this as a simple buck regulator, without first

reading this explanation! But it is. To make a compact and robust power

supply, I indulged in the luxury of building it on a printed circuit

board. All of the parts are on the board, which is single-sided and has

all of the connections on them. It is doubtful to what extent other

builders will be able to use this board layout, because it is heavily

dependent on the sizes and shapes of the exact components I used.

Anyway I'm providing the design here, seen from the component side. If

you click on it, you will get a larger version. You can see roughly

what part goes where, although the parts are not identified, only

outlined. It should be easy enough to populate the board following the

schematic.

To make a compact and robust power

supply, I indulged in the luxury of building it on a printed circuit

board. All of the parts are on the board, which is single-sided and has

all of the connections on them. It is doubtful to what extent other

builders will be able to use this board layout, because it is heavily

dependent on the sizes and shapes of the exact components I used.

Anyway I'm providing the design here, seen from the component side. If

you click on it, you will get a larger version. You can see roughly

what part goes where, although the parts are not identified, only

outlined. It should be easy enough to populate the board following the

schematic. Here

is the board, just out of the ferric chloride bath. It has to be cut

down to its final size, drilled, the photoresist stripped off, and

protected by some solderable varnish.

Here

is the board, just out of the ferric chloride bath. It has to be cut

down to its final size, drilled, the photoresist stripped off, and

protected by some solderable varnish. And

here the board has been assembled. After assembly I applied a thick

coat of acrylic varnish, to prevent creepage between nearby traces and

pads. Only the input and ouput pads, which had not yet been

soldered, were protected with little pieces of masking tape before

spraying on the varnish.

And

here the board has been assembled. After assembly I applied a thick

coat of acrylic varnish, to prevent creepage between nearby traces and

pads. Only the input and ouput pads, which had not yet been

soldered, were protected with little pieces of masking tape before

spraying on the varnish. Seen

from the side, the compact built height of this power supply is

apparent. The room inside the base of my lathe is precisely 50mm high,

and the largest free space is 120x115mm. This dictated both the size of

the board, and the height of the tallest components. The full height of

the power supply, from the soldered pins to the tops of the tallest

parts, is 46mm.

Seen

from the side, the compact built height of this power supply is

apparent. The room inside the base of my lathe is precisely 50mm high,

and the largest free space is 120x115mm. This dictated both the size of

the board, and the height of the tallest components. The full height of

the power supply, from the soldered pins to the tops of the tallest

parts, is 46mm. And

here is another view. You can see how some power components are

installed with long legs, to raise them above the board and allow them

to get good air flow.

And

here is another view. You can see how some power components are

installed with long legs, to raise them above the board and allow them

to get good air flow.