Ferrite core loss in HF power applications

For broadband transformers in the high frequency range, the only really

usable core material is ferrite. Over the years several manufacturers

have developed and produced ferrite materials of various permeabilities

that can be used in HF power transformers, such as transmission antenna

baluns, power amplifier coupling and matching, or hybrid combiners, but

the manufacturers seem

to have striken a complot about not to publish the loss data for their

cores! While they do publish loss data for low-frequency cores made for

switching power supplies, the data sheets for almost all of their HF

cores do not include loss data for the radio frequency range. This

forces circuit designers to follow very imprecise rules of thumb, and

then experiment to find out whether the transformers will have

acceptable loss.

For several decades I designed my RF transformers in this way,

but

now (2019) I thought it was time to do something about it. So I spent a

good week of my time measuring the loss of 10 different ferrite cores,

in the frequency range of main interest to radio amateurs,

that

is, 1.8 to 54MHz, at flux densities in the range that would be used in

actual designs. This page presents the results, and my comments about

them.

The method

Each

core under test got a winding having a number of turns that would allow

driving the core to the desired level. This winding was fed from an HF

transceiver, using an antenna tuner when necessary, the coax cable then

going on to a dummy load. A 100:1 high

voltage scope probe connects to the winding, to measure the applied

voltage. The 100:1 ratio is necessary to keep the

probe from

burning out, since 10:1 probes normally don't survive enough RF voltage

to use them in this test. But the 100:1 ratio is also advantageous in

that the input impedance of such a probe is higher than that of a 10:1

probe, reducing the effect of the inductance of the probe tip and the

grounding clip and wire.

Each

core under test got a winding having a number of turns that would allow

driving the core to the desired level. This winding was fed from an HF

transceiver, using an antenna tuner when necessary, the coax cable then

going on to a dummy load. A 100:1 high

voltage scope probe connects to the winding, to measure the applied

voltage. The 100:1 ratio is necessary to keep the

probe from

burning out, since 10:1 probes normally don't survive enough RF voltage

to use them in this test. But the 100:1 ratio is also advantageous in

that the input impedance of such a probe is higher than that of a 10:1

probe, reducing the effect of the inductance of the probe tip and the

grounding clip and wire.

A temperature sensor was attached to each core under test, by means of

kapton adhesive tape and a small amount of thermally conducting grease.

For

each mesurement the core was wrapped in cotton, to serve as thermal

insulation. Some time was allowed for the temperature to stabilize,

then a

specific RF voltage was applied, calculated to produce the desired flux

density in the core, whose dimensions were accurately measured.

After a certain time, typically 3 minutes, the drive signal

was

shut off, and again some time was allowed for the temperature to

stabilize. The temperature rise was used together with the heat

capacity of the core to calculate how much energy had been lost as

heat, and this value was divided by the core volume to get the power

loss per

cubic centimeter of core material.

For

each mesurement the core was wrapped in cotton, to serve as thermal

insulation. Some time was allowed for the temperature to stabilize,

then a

specific RF voltage was applied, calculated to produce the desired flux

density in the core, whose dimensions were accurately measured.

After a certain time, typically 3 minutes, the drive signal

was

shut off, and again some time was allowed for the temperature to

stabilize. The temperature rise was used together with the heat

capacity of the core to calculate how much energy had been lost as

heat, and this value was divided by the core volume to get the power

loss per

cubic centimeter of core material.

After each measurement the cotton was removed, and a fan was used

to cool the core back down to room temperature. The average total time

needed for each measurement was around 15 minutes, adding up to several

hours per core.

The test frequencies were the low band edges of each of the amateur

bands related in approximate or exact 1:2 ratio: 1.8, 3.5, 7, 14, 28

and 50MHz. On each frequency two tests were done, at flux densities

having a 1:2 ratio. The voltage was calculated for each core, so as to

give the same two levels of flux density in all cores. The drive

voltage was kept constant on all frequencies for each of the two

levels, so that the flux densities decreased in inverse proportion to

frequency. This reflects exactly how such cores get used in many

practical situations: At constant voltage and constant power throughout

the

frequency range.

In some cases some additional measurements had to be done at

additional levels of flux density,

when one of the two main measurements was in a range where

precision suffered.

The results

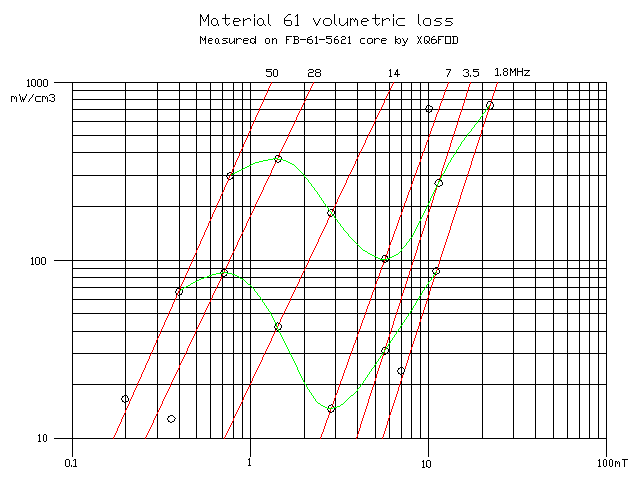

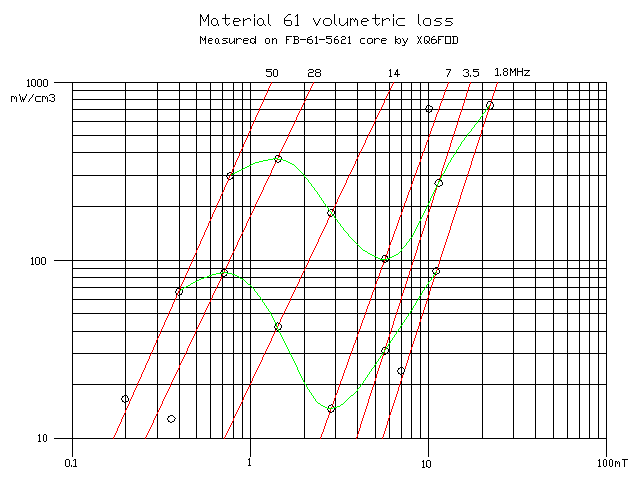

The

first core I tested was an FB-61-5621. This is a medium size cable bead

made of the material most commonly used by hams for low loss RF power

transformers. It has an initial permeability of 125. The part number is

the one used by Amidon, the distributor where I bought it. Fair-Rite,

the company manufacturing these cores, uses different part

numbers.

The

first core I tested was an FB-61-5621. This is a medium size cable bead

made of the material most commonly used by hams for low loss RF power

transformers. It has an initial permeability of 125. The part number is

the one used by Amidon, the distributor where I bought it. Fair-Rite,

the company manufacturing these cores, uses different part

numbers.

The little circles in the graph represent the actual measured values. I

drew the red loss curves as straight lines across the two measurements

that I thought are the most relevant. The manufacturers mostly draw

them as straight lines too, for the ferrites for which they do give

such curves, but I would be very surprised if these

should truly

be straight lines! But drawing these curves as they really

are,

slightly bent, would require at least 4 to 5 measurements per

frequency, and I didn't want to spend the rest of my life measuring

ferrite loss...

It's important to keep in mind, then, that in my graphs the parts of

each line that lie between the two measurement values used to draw it,

and close to them, are the most accurate, while any extensions of those

lines into a range where I made no measurement becomes increasingly

inaccurate. The important point here is that my measurements cover the

levels of flux density most likely used in practice, so that these

graphs can be used quite well for design.

The two green lines directly represent the volumetric loss of the

ferrite through the spectrum, at the two fixed drive levels. The upper

green line always represents a drive level such that a flux density of

22mT results on 1.8MHz, and the lower green line is at half that flux

density. So these green lines allow directly comparing the loss of one

ferrite to that of another. This is much easier to visually interpret,

than the red loss lines per frequency.

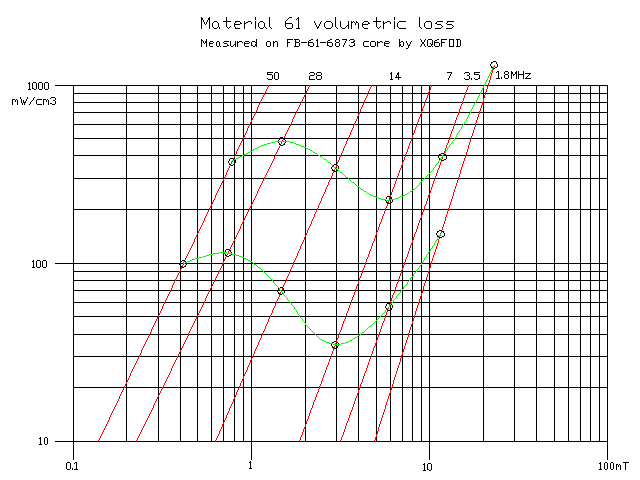

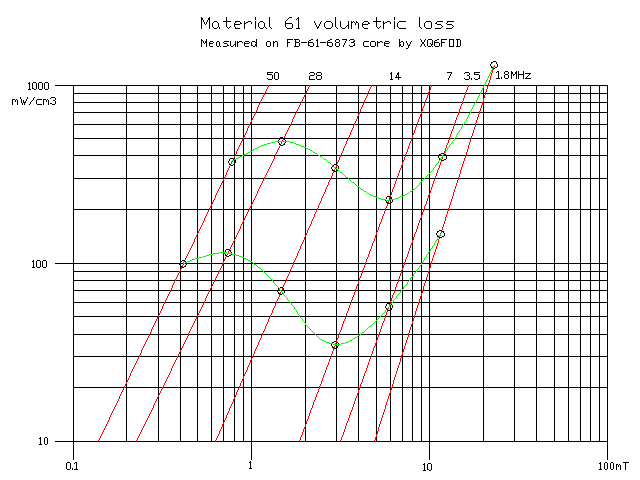

61 ferrite turned out to have a very idiosyncratic loss curve, with a

very low loss at 7MHz, the loss rising toward both higher and lower

frequencies, but dropping again when going beyond HF into the low VHF

range. I won't risk any explanation for this behaviour; I just present

the facts, as measured.

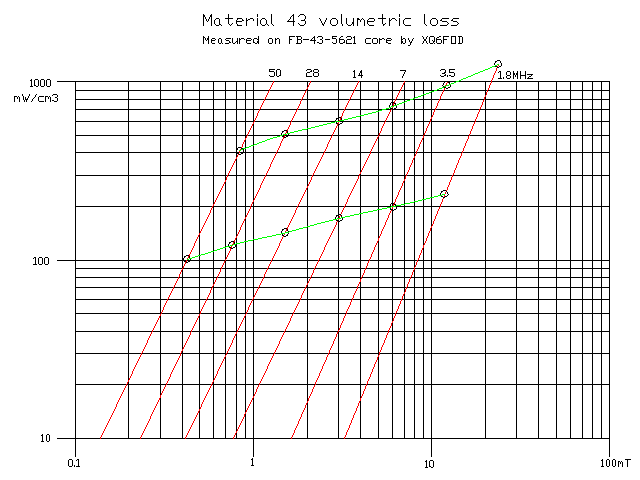

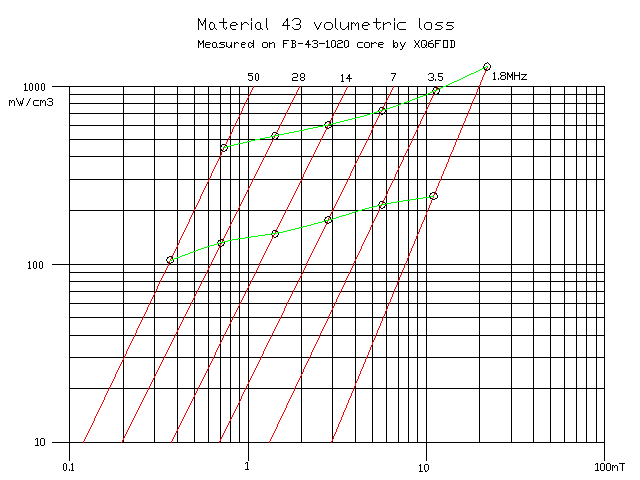

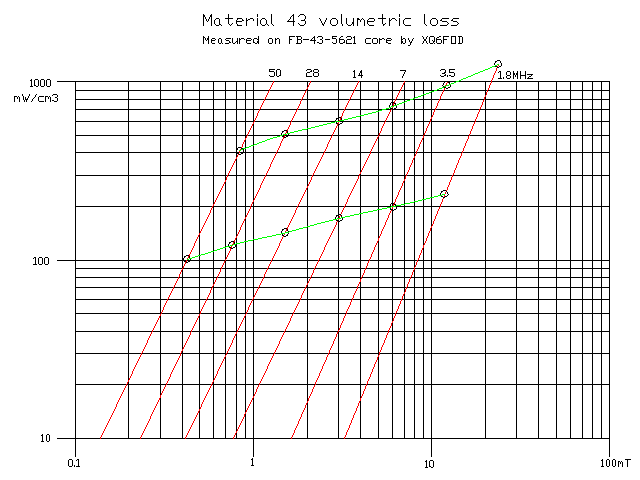

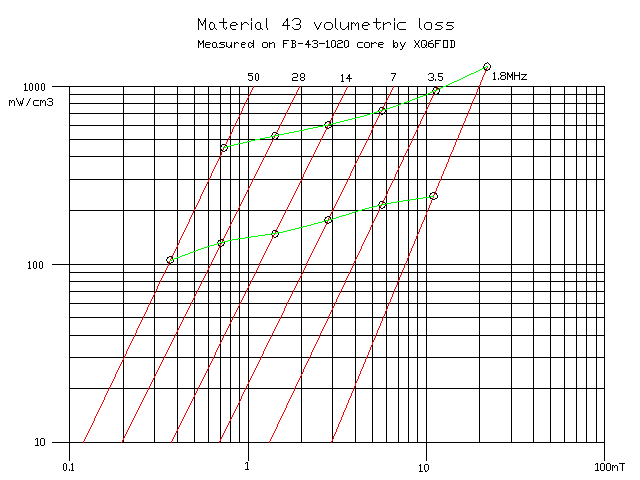

The

next core I measured was of the same nominal size, but

made from material

43, which has a much higher initial permeability of 850.

The

next core I measured was of the same nominal size, but

made from material

43, which has a much higher initial permeability of 850.

The behaviour of this material was extremely smooth, even, predictable,

almost boringly so. This looks nice at first sight - but the loss was

also higher than that of the 61 material, on all frequencies!

Note that at high flux density on 1.8MHz, the loss of material 43

turned out only out 60% higher than that of material 61. But on 7MHz,

where 61 has its sweet spot, 43 is 7 times more lossy than 61, at high

flux density, and a whopping 15 times more lossy than 61 at moderately

low flux density!

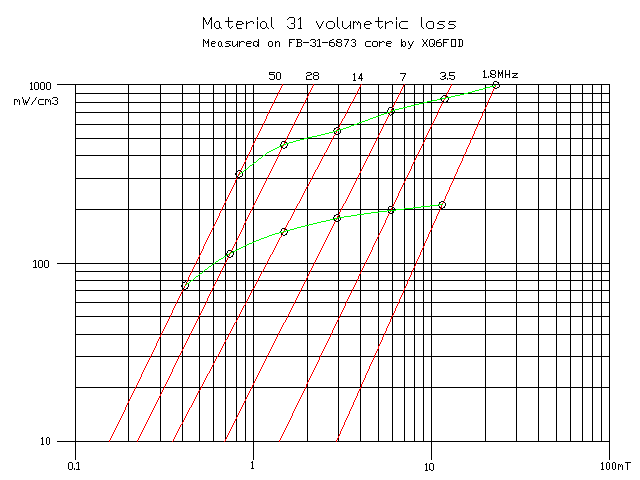

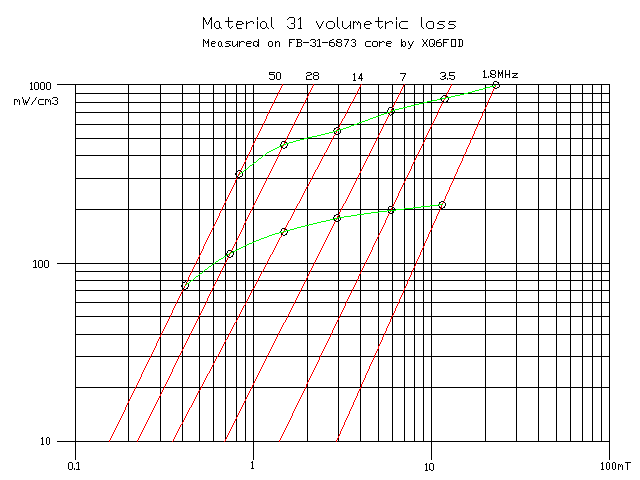

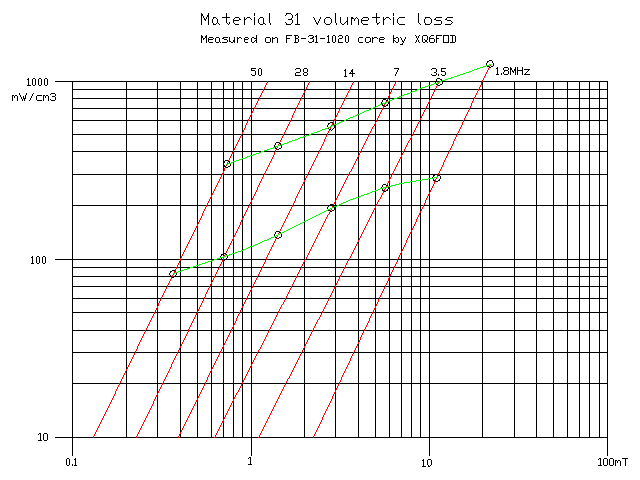

A

lot has been written in the last few years about material 31. Most RF

cores are made from nickel/zinc ferrites, while low frequency cores are

manganese/zinc ferrites. Manganese/zinc ferrite has fundamentally

higher permeability, its loss increases less with flux density

than in nickel/zinc ferrites, but it's also much more conductive than

nickel/zinc, and has far lower velocity of propagation, which leads to

dimensional resonance problems at RF. These two

latter characteristics make most manganese/zinc poor for RF

transformers.

A

lot has been written in the last few years about material 31. Most RF

cores are made from nickel/zinc ferrites, while low frequency cores are

manganese/zinc ferrites. Manganese/zinc ferrite has fundamentally

higher permeability, its loss increases less with flux density

than in nickel/zinc ferrites, but it's also much more conductive than

nickel/zinc, and has far lower velocity of propagation, which leads to

dimensional resonance problems at RF. These two

latter characteristics make most manganese/zinc poor for RF

transformers.

But all the characteristics of a ferrite material depend not only on

its basic formulation, but also on many details of the manufacturing

process, over which the manufacturer has ample control. And so the

Fair-Rite company came out with this material 31, which is an

RF-suitable

manganese/zinc material having a permeability of 1400, which is very

high for RF

use. I bough a small selection of material 31 cores, to try this

material.

The results show that the material very much resembles 43, in terms of

loss. The difference in loss is too slim to be enough reason to choose

between 31 and 43. But where its higher

permeability is an advantage, 31 is really the material to

use.

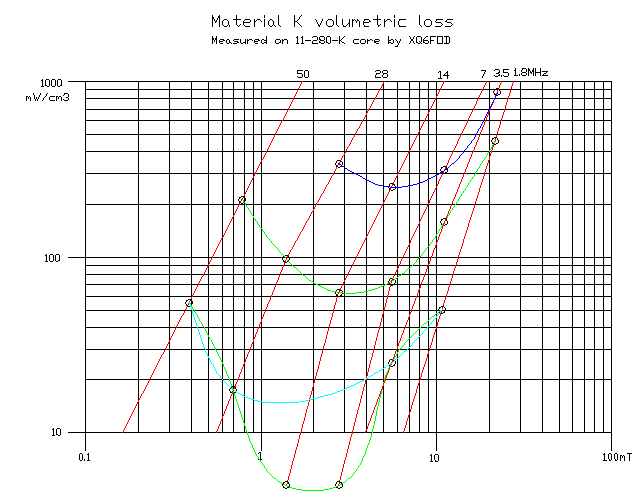

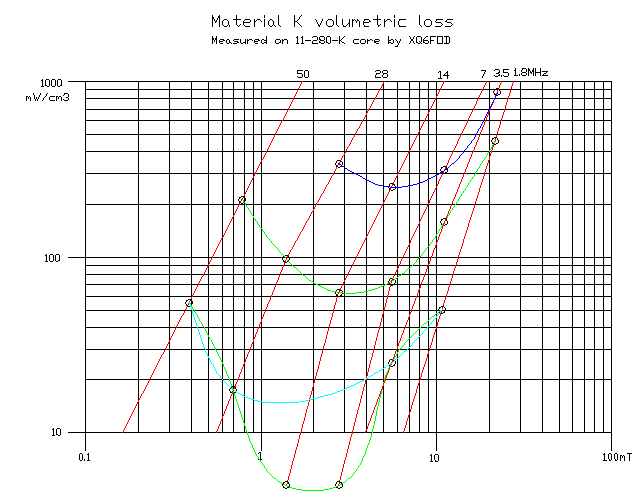

Several

years ago I received a gift from a friend and fellow ham, whose health

was failing to

such a degree that he knew he wouldn't ever again need the ferrite

cores and other parts he had stocked. Nando, rest

in peace. His gift included a nice assortment of magnetic cores, among

them some "Ferronikits", which are kits of many cores of different

sizes, of a specific material and type, made by the company Ferronics.

Among these kits is one of material K binocular cores, and another of

material K toroids. I used one of the largest toroids to measure its

loss.

Several

years ago I received a gift from a friend and fellow ham, whose health

was failing to

such a degree that he knew he wouldn't ever again need the ferrite

cores and other parts he had stocked. Nando, rest

in peace. His gift included a nice assortment of magnetic cores, among

them some "Ferronikits", which are kits of many cores of different

sizes, of a specific material and type, made by the company Ferronics.

Among these kits is one of material K binocular cores, and another of

material K toroids. I used one of the largest toroids to measure its

loss.

Material K is something special: A cobalt/nickel/zinc ferrite. It

has the same initial permeability as Fair-Rite 61, but thanks to a

small cobalt oxide addition and special processing it has exceedingly

low loss. The shape of its basic loss curve is similar to that

of material 61,

having a pronounced loss dip, in this case more toward 14MHz than 7MHz.

Unlike 61, material K has higher loss on 50MHz than on 28MHz - but

still lower than 61! Ferronics K is the lowest loss material I tested.

The two lowest measurement points are so low that they are in a range

where my test setup suffers from severe resolution problems: The

temperature rise was just 0.2°C, and my thermometer has a resolution

of 0.1°C, so the resolution-induced uncertainty is 50%! In the interest

of scientific honesty, I drew those points anyway - but don't trust

them. I drew the light blue loss curve that leaves out these two

suspect points. But I think that the actual loss curve probably lies

about halfway between the light blue and the lower green one.

On four frequencies I also had to make additional measurements at twice

the normal "high" drive level I used, to be able to get data for the

volumetric loss range that causes significant warming. That's the dark

blue curve. No other material could be driven to such a high flux

density on those frequencies without overheating in a matter of seconds.

If you can get Ferronics K cores, use them.

Note that the material K cores sold by Amidon are not

this Ferronics K material. They are rated at an initial permeability of

290, and I understand that they are made by yet another company. I

didn't test Amidon K material, because I don't have any of it. It would

have been interesting to test it.

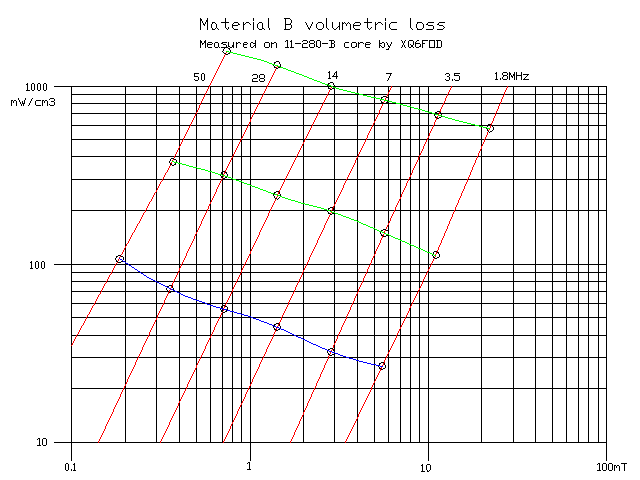

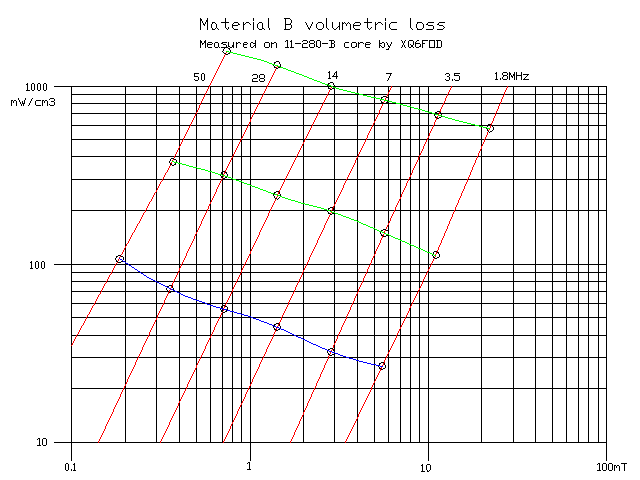

Another

of the Ferronikits I got from Nando contains toroids made from material

B. That's not an RF material. It's a high permeability manganese/zinc

ferrite, made for low frequency pulse transformers and the like. Just

for comparison, I tested the largest toroid of this kit, which is the

same size

as the material K toroid I tested.

Another

of the Ferronikits I got from Nando contains toroids made from material

B. That's not an RF material. It's a high permeability manganese/zinc

ferrite, made for low frequency pulse transformers and the like. Just

for comparison, I tested the largest toroid of this kit, which is the

same size

as the material K toroid I tested.

The characteristics turned out totally different from RF materials.

While the loss on 1.8MHz was roughly in the same range as that of RF

materials,

the loss of material B increases

with frequency, at constant

drive level, while in all RF materials it decreases.

So the loss of

material B in the high HF range and on 50MHz is very high. So

high in fact, that I had to run a third set of measurements, at an

extra low

drive level, to find out the loss in the range one could actually use

this material. That's the dark blue curve.

At sufficiently low drive levels, even this material could be used at

RF, but there is no reason to do so, since material 31 is available,

provides a high permeability, and much lower loss.

Note that I always have 1.8-54MHz applications in mind.

Instead if

just one band, or a a few bands, need to be covered, matters can change

a lot. In a pure 1.8MHz application, for example, material B would

be a good choice.

Given that I was already measuring non-RF materials, I also started

measuring the loss of a material 77 core. This is the main material

sold by Fair-Rite and Amidon for power applications in the 20-100kHz

range, typical for switchmode power supplies. It's a manganese/zinc

ferrite having an initial permeability of 2000. Some hams do

use

this material in RF applications. But my measurements turned out so

bad, that I decided to stop testing it, and I didn't draw a graph.

Suffice it to say that material 77 has similar loss characteristics as

material B, its loss rising with frequency at constant drive level, but

also the loss is much higher than for B!

Also some hams use material 73 in RF transformers. Unfortunately the

only cores I have in material 73 are small wire beads. They are too

small to let me accurately measure their loss with my setup, and also

the

diameter ratio of those beads is too high to produce reliable results.

Magnetic flux crowds in the small-radius areas of a core, and when the

diameter ratio is too high, this effect seriously impacts the accuracy

of material loss measurements.

Having

run out of materials to test, I decided to test some cores made of the

same

materials but in other sizes. The 61 and 43 cores I tested

first

were of the same size, but the 31 core was slightly larger. Since I

have some material 61 cores of the same size as that 31 core,

I tested it.

Having

run out of materials to test, I decided to test some cores made of the

same

materials but in other sizes. The 61 and 43 cores I tested

first

were of the same size, but the 31 core was slightly larger. Since I

have some material 61 cores of the same size as that 31 core,

I tested it.

The result was surprising: While the loss curves have the same shape

than for the smaller 61 core, the volumetric loss is significantly

higher! This much

difference cannot come from my measurement setup. It's clear that

ferrites are not always very consistent, in terms of loss.

Material 61, like several other low permeability materials, can be

damaged by excessively intense magnetic fields. The

manufacturers

warn about this, but don't say how much is safe! Exceeding the limit

will increase both the losses and the permeability, according

to the lterature. Anyway this

core was taken fresh from the package for testing, so I'm sure that I

haven't applied a strong field to it. But could it be that it

was

exposed to such a field somewhere else, before I got it?

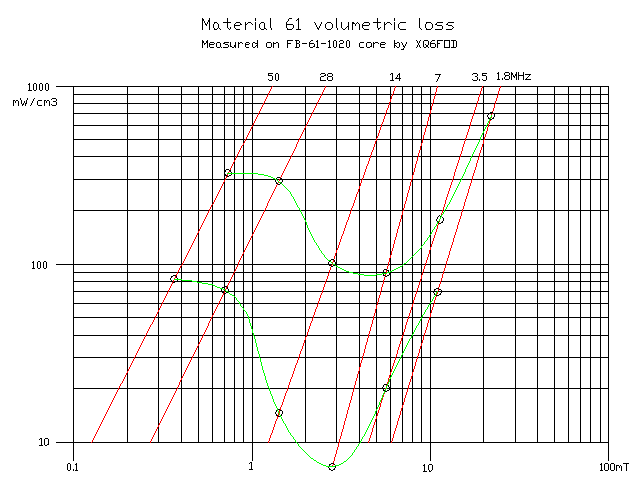

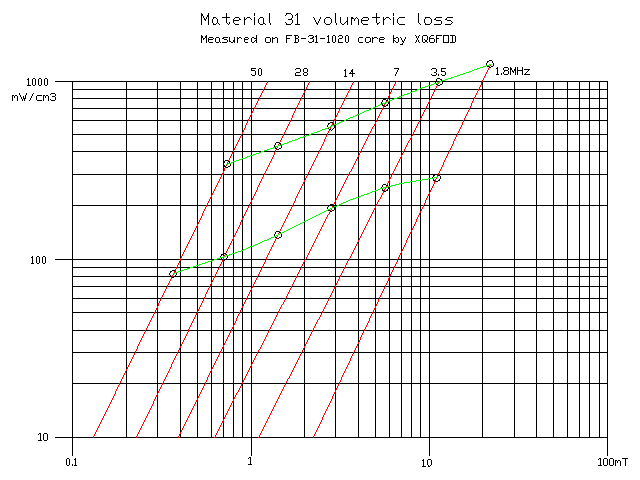

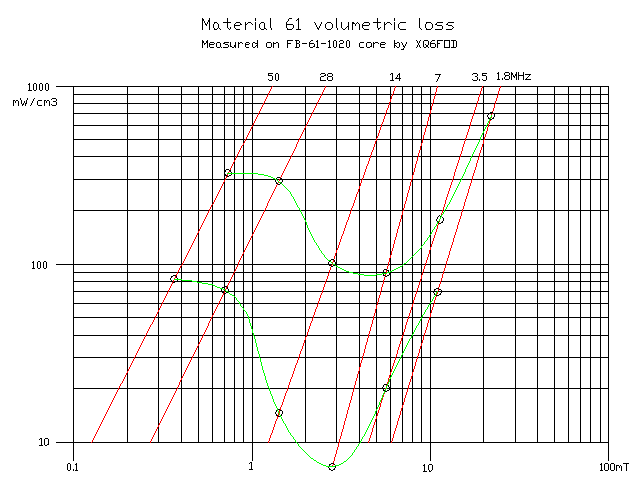

Digging

deep in my treasure chest, I found three cores of identical size,

Amidon FB-1020, in all three most-used Fair-Rite materials: 61, 43 and

31. So I measured their loss.

Digging

deep in my treasure chest, I found three cores of identical size,

Amidon FB-1020, in all three most-used Fair-Rite materials: 61, 43 and

31. So I measured their loss.

The FB-61-1020 bead has loss curves very close to those of the

first,

smallest bead I tested. This was reassuring, as it suggests that there

are no hidden flaws in my measurement method, that would make it overly

size-sensitive. And it also suggests that my FB-61-6873 core

has

abnormally high loss.

The

material 43 bead of the same size shows very much the same volumetric

losses as the much smaller bead I tested first. This suggests that

material 43 has better part-to-part consistency than material 61, but

it's not a good idea to judge this from just two samples...

The

material 43 bead of the same size shows very much the same volumetric

losses as the much smaller bead I tested first. This suggests that

material 43 has better part-to-part consistency than material 61, but

it's not a good idea to judge this from just two samples...

And

the third in the group, the same-size material 31 bead, shows a loss

close to that of its smaller brother, but not as close as the two 43

siblings. This suggests a theory: Within each family (manganese/zinc or

nickel/zinc), the lower permeability members show wider

dispersion of their loss characteristics. And this might be due by the

low permeability being implemented by means of a distributed air gap

(more filler, less ferrite in the final mix), just like in powdered

metal cores, rather than by changing the basic formulation of the

ferrites. But I'm purely guessing this.

And

the third in the group, the same-size material 31 bead, shows a loss

close to that of its smaller brother, but not as close as the two 43

siblings. This suggests a theory: Within each family (manganese/zinc or

nickel/zinc), the lower permeability members show wider

dispersion of their loss characteristics. And this might be due by the

low permeability being implemented by means of a distributed air gap

(more filler, less ferrite in the final mix), just like in powdered

metal cores, rather than by changing the basic formulation of the

ferrites. But I'm purely guessing this.

The accuracy of these measurements

While I tried to work in a consistent, careful and repeatable manner

while measuring the loss of these cores, the result shouldn't be

considered to be highly accurate. There was always some heat loss

through the test winding, some extra heat generated by copper loss in

that wire, cotton isn't a perfect thermal insulator, the temperature

sensor isn't perfectly coupled to the core and does conduct some heat

away through its cable, and so on. In the very low loss range the

resolution of my temperature measurements is poor, the oscilloscope

used to measure the applied voltage only has

a 100MHz

bandwidth, which means that at 50MHz it could already have a

significant error, the scope probe is rated at 250MHz but was

used with its grounding clip pigtail, and so on. Despite all this, I

think that my

measurements are still usable, since the characteristics of

ferrite

materials themselves aren't highly precise. But one issue worries me

more than the sum of all others: I didn't find really trustworthy,

consistent information about the heat capacity of ferrite materials. I

found values between 500 and 1250 J/kg/K published on the web, many of

those

sources don't say what type of ferrite is meant, nor even whether they

mean

ferrite as in magnetic cores, or bulk ferrites of various types.

Narrowing it down from all I could find, I finally used a value of

750 J/kg/K for all my materials, but surely this is not precise. If the

heat capacity of any of the materials is different from this

value, the curves I drew for that material should be shifted

according to that difference.

In case one material has a very different heat capacity than another,

this might significantly affect the relative merits of them, making any

hard conclusions drawn from my graphs a bit dangerous.

Ferrites vary their loss according to temperature. My tests were all

done with the cores starting from my room temperature, about 21 to

22°C, and heating up at most to 45°C. So the loss measured is

representative for normal "cool" operation, but not for cores that are

running really hot.

Which material should you use?

Among the widely available materials (from Amidon and others), and

considering only the ones tested here, 61 has the lowest loss,

but

also the lowest permeability. That's no news at all.

What could be news to many people, is that the difference in

practical use between materials is less than one would think! Although

they can have a large difference in loss at a given flux density and

frequency, the loss also varies at a very high rate with flux density.

So, the flux density at which a core can operate, for a fixed

amount of heating, varies only slightly between the various ferrite

materials!

For example, let's assume that in a given application, with a given

core size, a volumetric loss of 200mW/cm³ is acceptable. You now have

to look at the graphs, and see at which frequency the ferrites have

their highest loss, and see what flux density they can take at that

frequency, for 200mW/cm³ loss. Let's do this now, for a 1.8-54MHz

application. Here is the table I got:

Material K: 15mT at 1.8MHz.

Material 61: 12 to 14mT at 1.8MHz.

Material 43: 10 to 11mT at 1.8MHz.

Material 31: 9.2-11mT at 1.8MHz.

Material B: 0.23mT at 54MHz, thus roughly 7.3mT at 1.8MHz.

Let's forget about material B, which isn't an RF material. All the

others fall in a range of 9.2 to 15mT, at 1.8MHz. That's an important

difference, but not a really dramatic one! In a critical application

you would want to get material K, if you can, and otherwise stick to

61, and see if you can get enough inductance from them at the low end

of the spectrum. Instead in a less critical situation you would use

any material you happen to have on hand, and just be sure to use enough

turns per volt to keep the flux density low enough. Using more turns,

or larger cores, reduces the upper frequency limit of a

transformer, and that's why in a critical application you need to be

careful with this. Equal-delay transmission line transformers

(Guanella) give you a whole lot more headroom in this regard.

Note that the selection of material is dependent on the

allowable volumetric loss. For example, let's assume that you will

make a very small transformer. In these a much higher volumetric loss

is acceptable, due to their higher surface-to-volume ratio, unless the

insertion loss becomes a problem from the point of view of signal

attenuation. Let's assume you can tolerate

1000mW/cm³. In this case, at 1.8MHz:

Material K: 28mT

Material 61: 20.5 to 23mT

Material 31: 20 to 22mT

Material 43: 20 to 21mT

Except for our clear winner, Ferronics K, the other three are pretty

much in a tie!

And now let's go to the other extreme, when you have large cores, no

forced-air cooling, and continuous operation, so that you can only

accept 50mW/cm³ of core loss:

Material K: 10mT

Material 61: 8 to 9mT

Material 43: 5.7 to 6.2mT

Material 31: 4.8 to 6mT

Material K wins again, but 61 is close, the other two falling way

behind. Note that both K and 61 are actually limited by the high

frequency end, having slightly higher loss there than at the low end,

at this low drive level.

And if you have an application that only needs a smaller frequency

range, things change again.

This entire page is just about the loss of ferrite cores, but core

loss is just one of several things you need to keep in mind when

selecting the best material for a given application, and then select

the shape and the size of the core. Here are some other considerations:

Initial permeability: The materials tested here vary between 125 and

5000. That's a huge range! Some people think "the bigger the better",

other's think "enough is enough", but few realize all the

implications of using materials of different permeabilities. Firstly,

it's important to understand that the permeabilities really vary only

in the lower frequency range. By 50MHz all of these ferrites have

nearly the same permeability. Also at the low end of our frequency

range the differences are already smaller than the very low frequency

initial permeabilities suggest:

K: 125, highly inductive

61: 135, highly inductive

43: 550, with significant resistive component

31: 1100, with high resistive component

Note that these are the initial

permeabilities, that is, the ones the materials show at extremely small

flux density. At higher drive levels they change - specially the

resistive component grows much larger. This effect is stronger in

nickel/zinc ferrites than in manganese/zinc ones - you can see it by

comparing the steepness of the 1.8MHz loss lines of 61 and 31 ferrites.

That of 61 is much steeper.

A higher permeability can save the day, which is why many people

love material 31. But it can also be a big liability. For

example, when

there is any net DC present in the windings. At a given core size,

turns number and DC flowing in those turns, the DC flux density in the

core is

in direct proportion to its very-low-frequency permeability. Said

clearly, a 31 core will have to carry 11 times as much DC flux as a 61

core! Very often this is critical in power amplifiers. While a 31 core

would be totally saturated by a given DC, a 61 core might handle

it comfortably. With low permeability ferrite you

can often

just forget about imbalance currents in bifiliar chokes, for example -

they typically won't cause trouble. Instead with high permeability

ferrite even a small imbalance in a push pull amplifier might saturate

the core!

Also an excessive permeability extends the response of a transformer

down into an uneeded, and often unwanted, frequency range. It's

typically an aid to amplifier stability to use transformers that have

just enough bandwidth.

This extension of frequency response can be a real problem, when it

extends so low that it reaches the higher components of the envelope

signal, in transformers or chokes that carry a DC supply. In that case

distortion can be caused, which manifests

in splatter. So there are many good reasons to design

transformers in such a way that they respond only over the desired

frequency range, and not much beyond. And that often means that a

specific permeability is optimal for a specific design. Not the highest

one and not the lowest one, but the right one.

Another consideration is thermal effects. When a core runs warm, it

changes its characteristics. In an extreme case, it can reach its Curie

temperature, and at that point you no longer have a magnetic core, and

the amplifier blows up! Material 43 has a Curie temperature of only

135°C. Material 31 is even lower! Instead material 61 and

material K both have it above 350°C, so it will never be reached in any

normal circuit. Now you might say that 130°C also won't ever be

reached. Be careful about that, though. Ferrites are poor thermal

conductors, and the temperature inside the

core can

get much higher than that on its surface! The larger a core

is, the more severe this effect becomes. So, in applications that

might run very hot, you might be forced to use a material that has a

high enough Curie point.

Cost and availability are powerful factors in deciding what core to

use. Materials 61, 43, 31, and a few more, are widely available through

Amidon and a few other distributors. Some amplifier builders have used

Laird 28 material, which is available from some mainstream parts

distributors. It has slightly lower permeability than 43 and might be a

good choice, but specifications given by Laird are very thin. The

complex permability graph they publish suggests that the material is

less lossy than 43, but that's just the initial permeability, and it

says

little about the loss at higher flux densities. I don't have any Laird

28 cores here, so I can't test them. The same happens with cores from

manufacturers like TDK, Ferroxcube, Kaschke, and several others. As

long as I can't find a place where I can order them online, paying by

Paypal or the like, and have them shipped to me by mail for a

reasonable charge, I can't use those cores.

The cost of material 43 and 31 tends to be the same, while 61 is more

expensive. That's a good reason to avoid 61when you can. On the other

hand, in many circuits the cost of ferrite cores is small compared to

that of other parts, such as high power transistors. This makes it

reasonable to choose the best cores, regardless of a few dollars

difference in their total cost.

Saturation flux density is of no importance in pure RF work, because a

core will dramatically overheat at flux densities far lower than its

saturation level. The exception could be pulsed operation at a very

high peak-to-average ratio, but I'm writing this page mostly for

homebrewing radio amateurs, and we hams don't use such narrow pulses.

But

always keep in mind the problems associated with DC. If

there is any chance that DC will flow in a winding, you need to

evaluate what effects it will cause. A material combining high

saturation flux density with low permeability tolerates the highest DC

drive. But don't forget that materials like 61 and K are degraded by

high flux density, and we are not told how much is safe!

A minor point to keep in mind is the electrical conductivity of the

materials. Generally nickel/zinc ferrites are essentially good

insulators, while manganese/zinc ferrites are bad conductors. If you

use any manganese/zinc ferrite, including material 31, you need to keep

in mind that it is slightly conductive, and insulate it where needed.

Life has never been easy. And ferrite cores are worse than life in that

regard.

Back to homo ludens electronicus.

Each

core under test got a winding having a number of turns that would allow

driving the core to the desired level. This winding was fed from an HF

transceiver, using an antenna tuner when necessary, the coax cable then

going on to a dummy load. A 100:1 high

voltage scope probe connects to the winding, to measure the applied

voltage. The 100:1 ratio is necessary to keep the

probe from

burning out, since 10:1 probes normally don't survive enough RF voltage

to use them in this test. But the 100:1 ratio is also advantageous in

that the input impedance of such a probe is higher than that of a 10:1

probe, reducing the effect of the inductance of the probe tip and the

grounding clip and wire.

Each

core under test got a winding having a number of turns that would allow

driving the core to the desired level. This winding was fed from an HF

transceiver, using an antenna tuner when necessary, the coax cable then

going on to a dummy load. A 100:1 high

voltage scope probe connects to the winding, to measure the applied

voltage. The 100:1 ratio is necessary to keep the

probe from

burning out, since 10:1 probes normally don't survive enough RF voltage

to use them in this test. But the 100:1 ratio is also advantageous in

that the input impedance of such a probe is higher than that of a 10:1

probe, reducing the effect of the inductance of the probe tip and the

grounding clip and wire. For

each mesurement the core was wrapped in cotton, to serve as thermal

insulation. Some time was allowed for the temperature to stabilize,

then a

specific RF voltage was applied, calculated to produce the desired flux

density in the core, whose dimensions were accurately measured.

After a certain time, typically 3 minutes, the drive signal

was

shut off, and again some time was allowed for the temperature to

stabilize. The temperature rise was used together with the heat

capacity of the core to calculate how much energy had been lost as

heat, and this value was divided by the core volume to get the power

loss per

cubic centimeter of core material.

For

each mesurement the core was wrapped in cotton, to serve as thermal

insulation. Some time was allowed for the temperature to stabilize,

then a

specific RF voltage was applied, calculated to produce the desired flux

density in the core, whose dimensions were accurately measured.

After a certain time, typically 3 minutes, the drive signal

was

shut off, and again some time was allowed for the temperature to

stabilize. The temperature rise was used together with the heat

capacity of the core to calculate how much energy had been lost as

heat, and this value was divided by the core volume to get the power

loss per

cubic centimeter of core material. The

first core I tested was an FB-61-5621. This is a medium size cable bead

made of the material most commonly used by hams for low loss RF power

transformers. It has an initial permeability of 125. The part number is

the one used by Amidon, the distributor where I bought it. Fair-Rite,

the company manufacturing these cores, uses different part

numbers.

The

first core I tested was an FB-61-5621. This is a medium size cable bead

made of the material most commonly used by hams for low loss RF power

transformers. It has an initial permeability of 125. The part number is

the one used by Amidon, the distributor where I bought it. Fair-Rite,

the company manufacturing these cores, uses different part

numbers. The

next core I measured was of the same nominal size, but

made from material

43, which has a much higher initial permeability of 850.

The

next core I measured was of the same nominal size, but

made from material

43, which has a much higher initial permeability of 850.  A

lot has been written in the last few years about material 31. Most RF

cores are made from nickel/zinc ferrites, while low frequency cores are

manganese/zinc ferrites. Manganese/zinc ferrite has fundamentally

higher permeability, its loss increases less with flux density

than in nickel/zinc ferrites, but it's also much more conductive than

nickel/zinc, and has far lower velocity of propagation, which leads to

dimensional resonance problems at RF. These two

latter characteristics make most manganese/zinc poor for RF

transformers.

A

lot has been written in the last few years about material 31. Most RF

cores are made from nickel/zinc ferrites, while low frequency cores are

manganese/zinc ferrites. Manganese/zinc ferrite has fundamentally

higher permeability, its loss increases less with flux density

than in nickel/zinc ferrites, but it's also much more conductive than

nickel/zinc, and has far lower velocity of propagation, which leads to

dimensional resonance problems at RF. These two

latter characteristics make most manganese/zinc poor for RF

transformers.  Several

years ago I received a gift from a friend and fellow ham, whose health

was failing to

such a degree that he knew he wouldn't ever again need the ferrite

cores and other parts he had stocked. Nando, rest

in peace. His gift included a nice assortment of magnetic cores, among

them some "Ferronikits", which are kits of many cores of different

sizes, of a specific material and type, made by the company Ferronics.

Among these kits is one of material K binocular cores, and another of

material K toroids. I used one of the largest toroids to measure its

loss.

Several

years ago I received a gift from a friend and fellow ham, whose health

was failing to

such a degree that he knew he wouldn't ever again need the ferrite

cores and other parts he had stocked. Nando, rest

in peace. His gift included a nice assortment of magnetic cores, among

them some "Ferronikits", which are kits of many cores of different

sizes, of a specific material and type, made by the company Ferronics.

Among these kits is one of material K binocular cores, and another of

material K toroids. I used one of the largest toroids to measure its

loss. Another

of the Ferronikits I got from Nando contains toroids made from material

B. That's not an RF material. It's a high permeability manganese/zinc

ferrite, made for low frequency pulse transformers and the like. Just

for comparison, I tested the largest toroid of this kit, which is the

same size

as the material K toroid I tested.

Another

of the Ferronikits I got from Nando contains toroids made from material

B. That's not an RF material. It's a high permeability manganese/zinc

ferrite, made for low frequency pulse transformers and the like. Just

for comparison, I tested the largest toroid of this kit, which is the

same size

as the material K toroid I tested. Having

run out of materials to test, I decided to test some cores made of the

same

materials but in other sizes. The 61 and 43 cores I tested

first

were of the same size, but the 31 core was slightly larger. Since I

have some material 61 cores of the same size as that 31 core,

I tested it.

Having

run out of materials to test, I decided to test some cores made of the

same

materials but in other sizes. The 61 and 43 cores I tested

first

were of the same size, but the 31 core was slightly larger. Since I

have some material 61 cores of the same size as that 31 core,

I tested it. Digging

deep in my treasure chest, I found three cores of identical size,

Amidon FB-1020, in all three most-used Fair-Rite materials: 61, 43 and

31. So I measured their loss.

Digging

deep in my treasure chest, I found three cores of identical size,

Amidon FB-1020, in all three most-used Fair-Rite materials: 61, 43 and

31. So I measured their loss. The

material 43 bead of the same size shows very much the same volumetric

losses as the much smaller bead I tested first. This suggests that

material 43 has better part-to-part consistency than material 61, but

it's not a good idea to judge this from just two samples...

The

material 43 bead of the same size shows very much the same volumetric

losses as the much smaller bead I tested first. This suggests that

material 43 has better part-to-part consistency than material 61, but

it's not a good idea to judge this from just two samples... And

the third in the group, the same-size material 31 bead, shows a loss

close to that of its smaller brother, but not as close as the two 43

siblings. This suggests a theory: Within each family (manganese/zinc or

nickel/zinc), the lower permeability members show wider

dispersion of their loss characteristics. And this might be due by the

low permeability being implemented by means of a distributed air gap

(more filler, less ferrite in the final mix), just like in powdered

metal cores, rather than by changing the basic formulation of the

ferrites. But I'm purely guessing this.

And

the third in the group, the same-size material 31 bead, shows a loss

close to that of its smaller brother, but not as close as the two 43

siblings. This suggests a theory: Within each family (manganese/zinc or

nickel/zinc), the lower permeability members show wider

dispersion of their loss characteristics. And this might be due by the

low permeability being implemented by means of a distributed air gap

(more filler, less ferrite in the final mix), just like in powdered

metal cores, rather than by changing the basic formulation of the

ferrites. But I'm purely guessing this.