Accelerometer

Many machines cause

vibration. Usually this is undesirable. Through improved balancing,

mounting on dampers, avoidance of resonant parts, and other measures,

it's very often possible to reduce the vibration to an acceptable

level. But when working on such a machine, it might be hard to guess,

by sight and feel, how much the vibration really is, and whether or not

it is improving through the work one is doing.

Many machines cause

vibration. Usually this is undesirable. Through improved balancing,

mounting on dampers, avoidance of resonant parts, and other measures,

it's very often possible to reduce the vibration to an acceptable

level. But when working on such a machine, it might be hard to guess,

by sight and feel, how much the vibration really is, and whether or not

it is improving through the work one is doing.

An instrument to measure vibration is then necessary. This is called an

accelerometer, because it measures the acceleration of the vibrating

parts. This is typically more useful than measuring the amplitude of

the vibration.

I built a simple accelerometer, triggered by my sister's need to track

down a machine in her neighborhood that robs her sleep by making the

walls vibrate in the night; but I also intend to use this meter to keep

track of the wear of my turbogenerator's ball bearings, among other

uses.

This is a very simple meter. It uses a monolithic three-axis

acceleration sensor with on-chip signal conditioning, which I built

into a little plastic case, along with a galvanometer and the necessary

electronics in between. The whole battery-powered instrument is simply

laid on the machine whose vibration is to be measured, or is held

against the vibrating wall. It has only a single scale, covering

accelerations of zero to one meter per second squared. The only control

is the power switch. The frequency range over which it has full

sensitivity spans 5 to 70 Hertz, which covers the frequencies at which

most machines exhibit their strongest vibrations. Outside this range,

sensitivity falls off at a rate of 6dB per octave, and above 150Hz it

falls off much sharper. The value indicated on the scale is the RMS

equivalent value of a sine wave vibration, present in the axis that is

vibrating the strongest. That means, this instrument joins the three

axes and always displays the highest value from among the

three.

This accelerometer could even be used to measure earthquakes, but a

significant portion of a typical earthquake's spectrum falls below 5Hz,

so the sensitivity will be a bit lower than it should. If you want to

use this meter to measure earthquakes, you should expand its

low frequency response by increasing C9, 10, and 11, at the cost of

higher noise. That would also require slowing down the decay rate, by

increasing C16.

The noise level of the sensor I used is about 0.05 m/s^2. Any vibration

to be measured must be clearly stronger than this, or it will be buried

in the meter's noise, and thus undetectable.

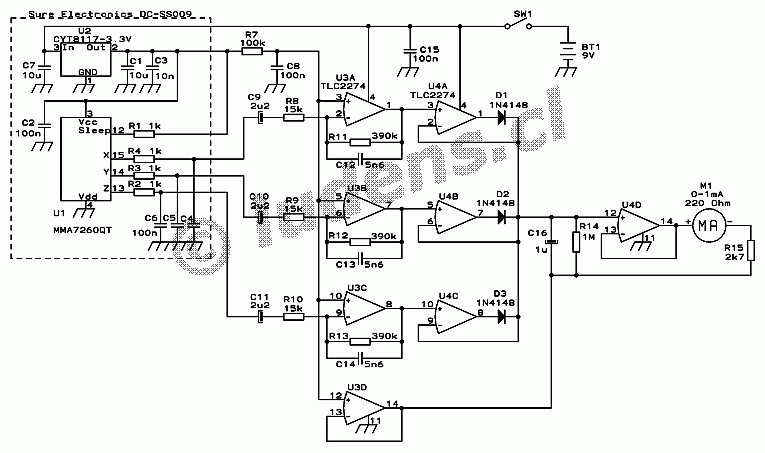

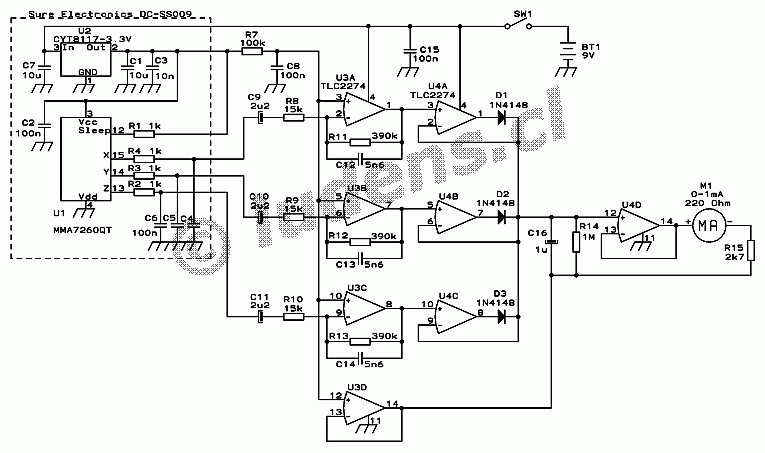

You

can click on this schematic to get a higher resolution version, for

printing.

You

can click on this schematic to get a higher resolution version, for

printing.

The sensor chip is an MMA7260QT. Since this IC is a surface mount

device that has connection pads under the body, it's hard to solder

with hand tools. When I bought it, I still had no reflow soldering

equipment, so instead of buying the chip alone, I bought a little

module offered by Sure Electronics on eBay, that has the chip mounted

on a little circuit board, along with a 3.3V regulator and bypass and

filtering components. This module can be easily integrated into the

rest of the circuit, which I built on universal prototyping board.

The circuit is pretty simple: Each of the three outputs of the sensor

is amplified by independent frequency-shaping amplifiers, and then the

three signals are joined in superdiode circuits that react to the

highest peaks present in any of the three channels. There is a one

second time constant filter, and then a 0-1mA galvanometer as display

device, with the appropriate voltage followers in between. The op amps

are directly powered from a 9V battery, and their bias voltage is

simply taken from the regulated 3.3V present in the sensor module.

There are no trimpots to calibrate the instrument. I don't have access

to any well calibrated reference accelerometer, so there would be no

point in playing with a trimpot and guessing where to set it. Instead

the resistor values were calculated so that the meter will show a

reasonably accurate RMS value of acceleration, assuming that the

vibration has a sine shape, and that the sensor chip actually

produces the output level stated in its data sheet. This seems to be

true, to a level that is good enough. But if the galvanometer you get

has a much different internal resistance than the one I got , which has

220 ohms, then you would have to change R15 accordingly, to

maintain proper sensitivity. The gain of the circuit is set so that if

the resistors and the sensor chip are all accurate, then exactly 2.814

volts across the combination of the meter and R15 should produce exact

full scale deflection. So you can see that my 2.7k resistor should

really be 2.594k, but I don't care for the tiny difference... and

anyway I used 5% resistors, so the uncertainty is larger!

Maybe this circuit is useful to you just as it is, or maybe you will

want to make additions or changes, depending on your needs. If you need

to measure the vibration separately in the three axes, it's a simple

matter to separate the channels in this circuit. You might also want to

add more scales to expand the measurement range. Be aware that you

cannot obtain greater sensitivity with this sensor,

because its

internal noise level is about 0.05 m/s^2. But you could perfectly well

add scales for higher accelerations. The sensor chip can be

configured to several spans, the most sensitive being 1.5 G (roughly 15

m/s^2), used, here, with the highest range topping out at 6 G. Also the

amplifiers

can be programmed for lower gain, by modifying the resistor values. Of

course the values of the capacitors in the amplifier circuits would

need to be modified accordingly, to maintain the desired frequency

response.

If you modify the circuit to measure high levels of vibration, of

course you will need to place the sensor module in a unit that's

separate from the box carrying the galvanometer! Otherwise the severe

vibration will damage the meter... But for the low vibration levels I

want to measure, it's fine to have everything in an integrated unit.

I built the instrument

using a ready-made plastic case. These are inexpensive, and very

practical, because they come internally ribbed so that PCBs can be

inserted in the

grooves, without requiring further fastening.

I built the instrument

using a ready-made plastic case. These are inexpensive, and very

practical, because they come internally ribbed so that PCBs can be

inserted in the

grooves, without requiring further fastening.

The 9V battery sits on the galvanometer, held in place by a piece of

scrap board and some plastic foam, which keeps it from rattling around.

The wiring is very simple: Only the battery, power switch and meter are

wired to the board. Everything else is on the board.

The

circuit was assembled on a piece of prototyping board that has a copper

pattern just like the solderless protoboards. I find this pattern the

most useful, and anyway these prototype PCBs are by far the most

convenient way to build simple one-of-a-kind circuits.

The

circuit was assembled on a piece of prototyping board that has a copper

pattern just like the solderless protoboards. I find this pattern the

most useful, and anyway these prototype PCBs are by far the most

convenient way to build simple one-of-a-kind circuits.

The Sure Electronics module is mounted just as if it were one more

component.

All of the small components (resistors, capacitors, diodes) for this

meter were recycled from junked electronic equipment. Old video

recorders, TVs, monitors, and other things, are a great

free source of lots of components. If you still don't

have a big junk box full of such electronic waste, it's high time that

you go and visit your local TV repairman, and ask him for some! With

modern consumer electronics being so cheap, a great many devices are

never repaired, and accumulate at the repair shops. Usually the shop

owners are happy to give them away for free, and recover the space they

took up!

I drew the meter scale in AutoCAD, printed it on plain paper with my

inkjet printer, and stuck the new scale on top of the galvanometer's

original scale, which is graduated in 0 to 1 milliamperes, using double

faced adhesive tape. There are also some freeware programs out there

that specialize in drawing meter scales, but being used to

AutoCAD, I prefer using it for all sorts of mechanical drawings,

including meter scales!

Back to homo ludens

electronicus.

Many machines cause

vibration. Usually this is undesirable. Through improved balancing,

mounting on dampers, avoidance of resonant parts, and other measures,

it's very often possible to reduce the vibration to an acceptable

level. But when working on such a machine, it might be hard to guess,

by sight and feel, how much the vibration really is, and whether or not

it is improving through the work one is doing.

Many machines cause

vibration. Usually this is undesirable. Through improved balancing,

mounting on dampers, avoidance of resonant parts, and other measures,

it's very often possible to reduce the vibration to an acceptable

level. But when working on such a machine, it might be hard to guess,

by sight and feel, how much the vibration really is, and whether or not

it is improving through the work one is doing. You

can click on this schematic to get a higher resolution version, for

printing.

You

can click on this schematic to get a higher resolution version, for

printing. I built the instrument

using a ready-made plastic case. These are inexpensive, and very

practical, because they come internally ribbed so that PCBs can be

inserted in the

grooves, without requiring further fastening.

I built the instrument

using a ready-made plastic case. These are inexpensive, and very

practical, because they come internally ribbed so that PCBs can be

inserted in the

grooves, without requiring further fastening.  The

circuit was assembled on a piece of prototyping board that has a copper

pattern just like the solderless protoboards. I find this pattern the

most useful, and anyway these prototype PCBs are by far the most

convenient way to build simple one-of-a-kind circuits.

The

circuit was assembled on a piece of prototyping board that has a copper

pattern just like the solderless protoboards. I find this pattern the

most useful, and anyway these prototype PCBs are by far the most

convenient way to build simple one-of-a-kind circuits.