T12 Soldering Iron Temperature Controller

When I

started in electronics, temperature-controlled soldering irons were

very expensive. Almost every electronician, and particularly poor

students like me, used some cheap and plain soldering iron instead, and

the more clever students hooked it up to a dimmer, to at least have

some degree of control over the temperature. But of course

the iron would cool down while soldering large items, and heat up a bit

too much when

left unused for a while.

When I

started in electronics, temperature-controlled soldering irons were

very expensive. Almost every electronician, and particularly poor

students like me, used some cheap and plain soldering iron instead, and

the more clever students hooked it up to a dimmer, to at least have

some degree of control over the temperature. But of course

the iron would cool down while soldering large items, and heat up a bit

too much when

left unused for a while.

Eventually I got rich enough to buy one of those very

expensive temperature-controlled Antex soldering irons, which

has served me well for roughly 35 years so far, going through several

dozen tips. But the time came when I got so immensely rich that I

wanted the luxury of a second

temperature-controlled soldering iron, so that I could keep one with a

tip for through-hole soldering, and another with a small SMD tip,

instead of having to constantly switch tips on a single iron. There

just was one

problem: While I got a lot richer than I was as a student, I never

ceased to be a cheapskate, so I didn't want to buy a second Antex!

Nowadays there are many Chinese soldering irons, and some of them are

actually good enough to use, although some others aren't...

Particularly I grew fond of the T12

soldering tips. These exist in many sizes and shapes, and they have a

thermocouple built right into the tip, which allows good temperature

control. They also have the heater built into each tip, which seems

like an overkill, but they are still cheap enough to not worry

about this. And in any case, having the heater in the tip provides the

best possible thermal conductivity, and thus a quick-heating, powerful

tool.

The heaters are designed for maximally 24V, and they run at over 60W

at that voltage. Even with as little as 11V they get hot enough to

solder not-too-big items. So I saw the chance to make a dual-use

soldering iron: In my lab it can serve as a second soldering iron for

SMD use, while in the field it can be used as a pretty versatile

battery-powered soldering iron, capable of soldering connectors and

large wires!

The Chinese makers sell a variety of controllers and power supplies for

the T12, but I chose to make my own, since it's easy, cheaper, and

gives me all the control to make exactly what I want. So I bought a

selection of T12 soldering tips, a handle for them, and I made

a little portable controller. The power input connector is an RCA phono

plug, which I use as my standard low-voltage supply connector for

devices

consuming up to about 3A.

There are both digital and analog controllers available. I personally

don't see an advantage in a digital one, because anyway the

thermocouples in these soldering tips aren't precise enough to allow

accurately measuring the temperature - even less so given that there is

usually no cold-junction compensation, and it would be unduly hard to

implement one. So all that's needed is a circuit that stabilizes the

temperature, and the user turns a knob to set the temperature so that

the iron solders well with the particular tip and solder type used. An

analog circuit does this best.

Many little analog controller boards are available that use variations

of a circuit based on the LM358 dual op amp. I had a look at

this circuit, but found it a bit stupid, because it is designed to

defeat the

LM358's totem-pole outputs, instead of using them to

advantage. In a circuit like this, actually open-collector outputs are

more suitable, and a comparator is also better suited than an op amp.

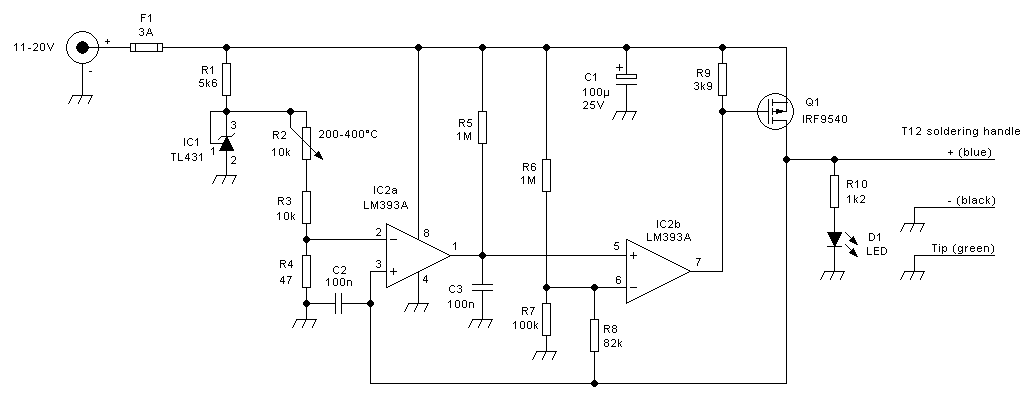

So I modified the "industry standard" circuit to use an LM393A dual

comparator, which features open-collector outputs, and resulted in

saving several components. This is the

result:

As usual with my schematics, you can click it to get a high resolution

version for printout.

The circuit is very simple, but its way of operation isn't immediately

obvious, so here is a functional description. To easily understand it,

you need to keep in mind that the LM393A has

open-collector outputs, and that the T12 soldering tips have a

thermocouple connected in series with the heater element.

When the circuit is first turned on, C3 is at zero charge, so IC2b gets

0V at its positive input, but some higher voltage at its negative

input, and thus its output is in logic low state, which means that the

open-collector output transistor is on. As a result Q1's gate gets

pulled to ground level, Q1 turns on, this applies the full input

voltage to the soldering iron's heater, and also lights the LED. In

addition the positive input of IC2a gets pulled up very high, way above

its negative input, so that this comparator sets its output to logic

high, which means turning its output transistor off.

As a result C3 can slowly charge through R5, until the voltage on it

exceeds the voltage on IC2b's pin 6. This voltage depends on the supply

voltage, but since the charging speed of C3 also depends on the supply

voltage, the time it takes for C3 to charge up to this level is

unaffected by the supply voltage (a ratiometric circuit). For example,

at 15V supply voltage

pin 6 will be at roughly 8.5V, which is given by the voltage divider

action between R7 pulling down to ground, and both R6 and R8 pulling up

to 15V.

When C3 exceeds this voltage, IC2b will change state, turning off Q1.

Now the drain of Q1, which is the positive side of the soldering tip's

heater and thermocouple series pair, will go to a very low voltage,

that

depends on the temperature the thermocouple has reached. It's of the

order of just a few millivolt. This pulls down the voltage on pin 6 to

only about 0.65V, making IC2b operate as a very strong Schmitt

trigger. Also the very low thermocouple voltage gets directly to pin 3

of

IC2a. C2 is there simply to bypass any RF interference that the

soldering

iron, wiring and circuit might pick up, and it is important

to locate this capacitor close to the IC, and sharing the same ground

point as R4. Pin 2 gets an adjustable, very low reference voltage,

produced by the variable voltage divider R2-R3-R4, from a regulated

2.5V reference created by IC1 and R1. The voltage at pin 2 can be

adjusted between aproximately 5.9 and 11.7mV. This equals the voltage

generated by the thermocouple of a T12 soldering tip for typically a

200-400°C range of temperatures.

As long as the soldering tip is at a temperature lower than the set

value, IC2a will

turn on its output transistor when Q1 turns off, very quickly

discharging C3 until its voltage falls below the 0.65V present on pin

6. Then IC2b will again turn on its output transistor, turning on Q1

and the heater element, which will again raise the voltage on pin 3,

turning off IC2a's output, allowing C3 to begin charging

again, to the 8.5V to which pin 6 has returned.

So, while the soldering tip is still colder then the selected

temperature, it will be powered with the full input voltage almost

continuously, only with very short interruptions to sense the

temperature. These dropouts are too brief to see them at the

LED, which visually stays continuously lit. The soldering tip heats up

pretty much as fast as possible at the present input voltage. C3 will

have a sawtooth wave on it, with a frequency of roughly 10Hz and a p-p

value of roughly one half the supply voltage.

When the tip has reached the desired temperature, the

situation changes: When

Q1 turns off, the thermocouple in the tip generates enough voltage to

keep pin 3 above pin 2. This keeps the output transistor of IC2a off,

allowing C3 to keep charging. So Q1 will remain off, for as long as

needed until the thermocouple has cooled below the set point. At that

time IC2a will turn its output transistor on, discharging C3, and this

will restart heating.

If there was an instantaneous thermal coupling between the heater and

the

thermocouple, the circuit would now operate with a fixed HEATER ON time

of about 0.1 second, and a variable HEATER OFF time as needed

to keep the temperature stable. But since there is some time lag

between the heater and the thermocouple, circuit operation gets a bit

slower, typically producing ON times of about 1 second (actually

composed of individual 0.1 second pulses with brief drops between

them), and OFF times that can reach up to 10 seconds or so. The LED

allows observing this clearly.

This

circuit works very well, but since IC1a compares such small input

voltages, it's critical to build it properly: You need to make sure

that the ground current flowing between the power input and the T12

negative wire doesn't cause any voltage drop affecting IC1a. The

easiest way to do this is to make a star ground point, to which 4

things are connected: The negative supply input, the negative

lead of the

T12, the ground of the tip, and a wire that goes to the

ground of the rest of the circuit. Ideally the LED negative

should also be connected to this star ground, or directly to the T12

negative. If you get the ground wiring wrong, the circuit will be

somewhat unstable, with the LED flickering a lot, or staying on and off

for longer times than it should, but even then you should get a pretty

decent temperature control of the tip.

This

circuit works very well, but since IC1a compares such small input

voltages, it's critical to build it properly: You need to make sure

that the ground current flowing between the power input and the T12

negative wire doesn't cause any voltage drop affecting IC1a. The

easiest way to do this is to make a star ground point, to which 4

things are connected: The negative supply input, the negative

lead of the

T12, the ground of the tip, and a wire that goes to the

ground of the rest of the circuit. Ideally the LED negative

should also be connected to this star ground, or directly to the T12

negative. If you get the ground wiring wrong, the circuit will be

somewhat unstable, with the LED flickering a lot, or staying on and off

for longer times than it should, but even then you should get a pretty

decent temperature control of the tip.

I built the circuit on a little scrap of perfboard, the kind

that has a copper pattern like a protoboard. I keep finding this the

most practical way to build single simple circuits like this. My star

ground point is at the lower left corner of the board. I used one

power trace to solder first the negative input, then the negative of

the T12, then the ground of the T12, and then the power trace runs on

to the

rest of the circuitry.

Note the cable ties placed tightly around each cable entering the box,

as strain reliefs.

Then I

put some globs of hot melt glue around those cable entries, also around

the LED (I used one of those nice-looking jumbo LEDs, but that's purely

a matter of taste), and also at two corners of the board, while a third

corner is supported by the potentiometer. This immobilizes all of the

stuff inside the box.

Then I

put some globs of hot melt glue around those cable entries, also around

the LED (I used one of those nice-looking jumbo LEDs, but that's purely

a matter of taste), and also at two corners of the board, while a third

corner is supported by the potentiometer. This immobilizes all of the

stuff inside the box.

There isn't much to say about the components, since these are all very

common and totally standard. The MOSFET doesn't need a heatsink. It

stays cold even without one. I used carbon film resistors having a 5%

tolerance, since that's good enough. Also I used ceramic multilayer

capacitors for C2 and C3. In the case of C3, a film capacitor would

give better stability of the oscillation frequency, but such stability

isn't needed at all, so I used the cheaper and smaller ceramic

capacitor. And

the fuse is a subminiature one, which has the size and shape of a

quarter watt resistor. It's soldered in place, because I

don't expect it to ever blow. That's the optimist in me, you know...

In my lab I power this soldering iron from 13.8V, because being a radio

amateur I have a big 13.8V supply constantly on. At this voltage, the

T12 heats to soldering temperature in about 30 seconds, and is powerful

enough for all PCB and connector work except the biggest

stuff. And when going into the field, I use a lithium ion battery made

from four 18650 cells in series, with a ready-made battery management

circuit that includes cell balancing. At the 16V provided by nearly

full cells, I can solder even coax connectors and thick wires.

I rated the circuit for 11 to 20V, because below 11V the heating power

of the T12 tips

is too low, and above 20V there is some theoretical risk of damaging

the MOSFET gate. If you really want to go to the full 24V rated for the

T12 tip, you might want to use a MOSFET with a 30V gate rating instead.

Or just risk it... The gates usually don't break down with such a

slight overvoltage. But if you manage to destroy your MOSFET, don't

tell anyone that I suggested this! :-)

In any case, I think that hardly anyone will need the full power a T12

tip develops at 24V.

Back to homo ludens

electronicus.

When I

started in electronics, temperature-controlled soldering irons were

very expensive. Almost every electronician, and particularly poor

students like me, used some cheap and plain soldering iron instead, and

the more clever students hooked it up to a dimmer, to at least have

some degree of control over the temperature. But of course

the iron would cool down while soldering large items, and heat up a bit

too much when

left unused for a while.

When I

started in electronics, temperature-controlled soldering irons were

very expensive. Almost every electronician, and particularly poor

students like me, used some cheap and plain soldering iron instead, and

the more clever students hooked it up to a dimmer, to at least have

some degree of control over the temperature. But of course

the iron would cool down while soldering large items, and heat up a bit

too much when

left unused for a while. This

circuit works very well, but since IC1a compares such small input

voltages, it's critical to build it properly: You need to make sure

that the ground current flowing between the power input and the T12

negative wire doesn't cause any voltage drop affecting IC1a. The

easiest way to do this is to make a star ground point, to which 4

things are connected: The negative supply input, the negative

lead of the

T12, the ground of the tip, and a wire that goes to the

ground of the rest of the circuit. Ideally the LED negative

should also be connected to this star ground, or directly to the T12

negative. If you get the ground wiring wrong, the circuit will be

somewhat unstable, with the LED flickering a lot, or staying on and off

for longer times than it should, but even then you should get a pretty

decent temperature control of the tip.

This

circuit works very well, but since IC1a compares such small input

voltages, it's critical to build it properly: You need to make sure

that the ground current flowing between the power input and the T12

negative wire doesn't cause any voltage drop affecting IC1a. The

easiest way to do this is to make a star ground point, to which 4

things are connected: The negative supply input, the negative

lead of the

T12, the ground of the tip, and a wire that goes to the

ground of the rest of the circuit. Ideally the LED negative

should also be connected to this star ground, or directly to the T12

negative. If you get the ground wiring wrong, the circuit will be

somewhat unstable, with the LED flickering a lot, or staying on and off

for longer times than it should, but even then you should get a pretty

decent temperature control of the tip. Then I

put some globs of hot melt glue around those cable entries, also around

the LED (I used one of those nice-looking jumbo LEDs, but that's purely

a matter of taste), and also at two corners of the board, while a third

corner is supported by the potentiometer. This immobilizes all of the

stuff inside the box.

Then I

put some globs of hot melt glue around those cable entries, also around

the LED (I used one of those nice-looking jumbo LEDs, but that's purely

a matter of taste), and also at two corners of the board, while a third

corner is supported by the potentiometer. This immobilizes all of the

stuff inside the box.